en-28

5 MAINTENANCE AND LUBRICATION

5.1 MAINTENANCE AND LUBRICATION CHARTS ______________________________

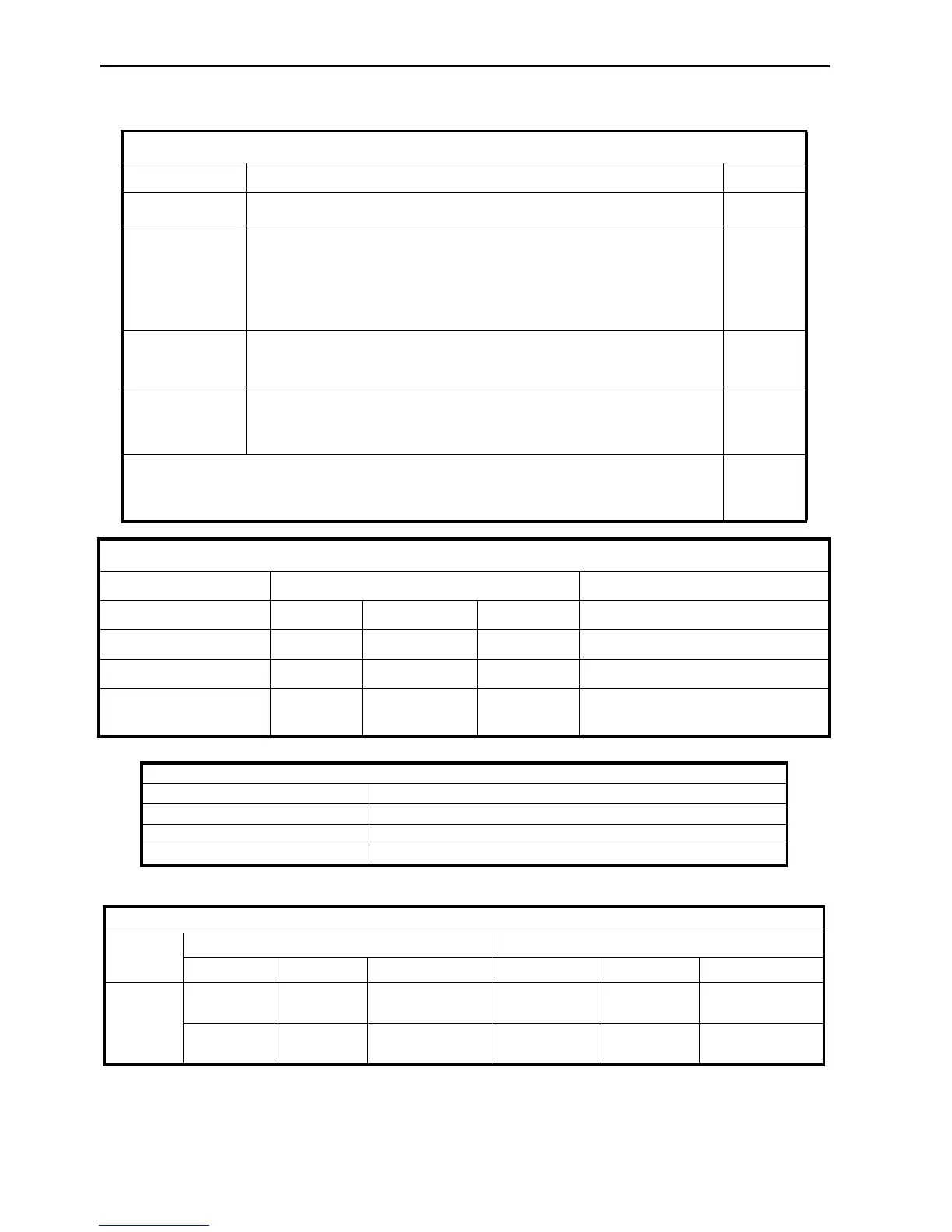

MACHINE SERVICE INTERVAL CHART

Interval Item Section

First 50 hours

Change the Hydraulic Charge Filter Element

8.5

Each day

10 hours

Check Safety Interlock System

Check the Hydraulic Fluid Level

Check Tyre Pressure

Check Engine Bay And Cooling System For Debris

7.2

8.5

4.2

8.10

Each week

Every 50 hours

Check for Loose Components

Check for Hydraulic Leaks

8.10

8.10

End of season

Every 1000

hours

Check Battery Condition

Change the Hydraulic Oil and Filter

8.9

8.5

Lubricate these fittings every week

A = All Lift Arm Pivots.

B = All Cutter Deck Caster Wheel Pivots.

8.24

FLUID REQUIREMENTS

Quantity Type

Engine Oil (with filter) 9.5 litres 2.1 Imp gals 2.51 US gals See Engine Oil Below

Hydraulic Oil (with filter) 50.2 litres 11.0 Imp gals 13.3 US gals Total Equivis ZS46 (ISO VG 46)

Radiator Coolant 7.6 litres 1.67 Imp gals 2.0 US gals 50% Anti-Freeze

Fuel 77.1 litres 17 Imp gals 20.3 US gals

Diesel to BS EN590:2009 or ASTM

D975 S15 (“Ultra Low Sulfur”)

Engine Oil: Must meet A.P.I. Standard CI-4.

TEMPERATURE VISCOSITY

More Than 25°C (77°F) SAE30 or SAE10W-30 or 15W-40

0°C to 25°C (32°F to 77°F) SAE20 or SAE10W-30 or 15W-40

Less Than 0°C (32°F) SAE10W or SAE10W-30 or 15W-40

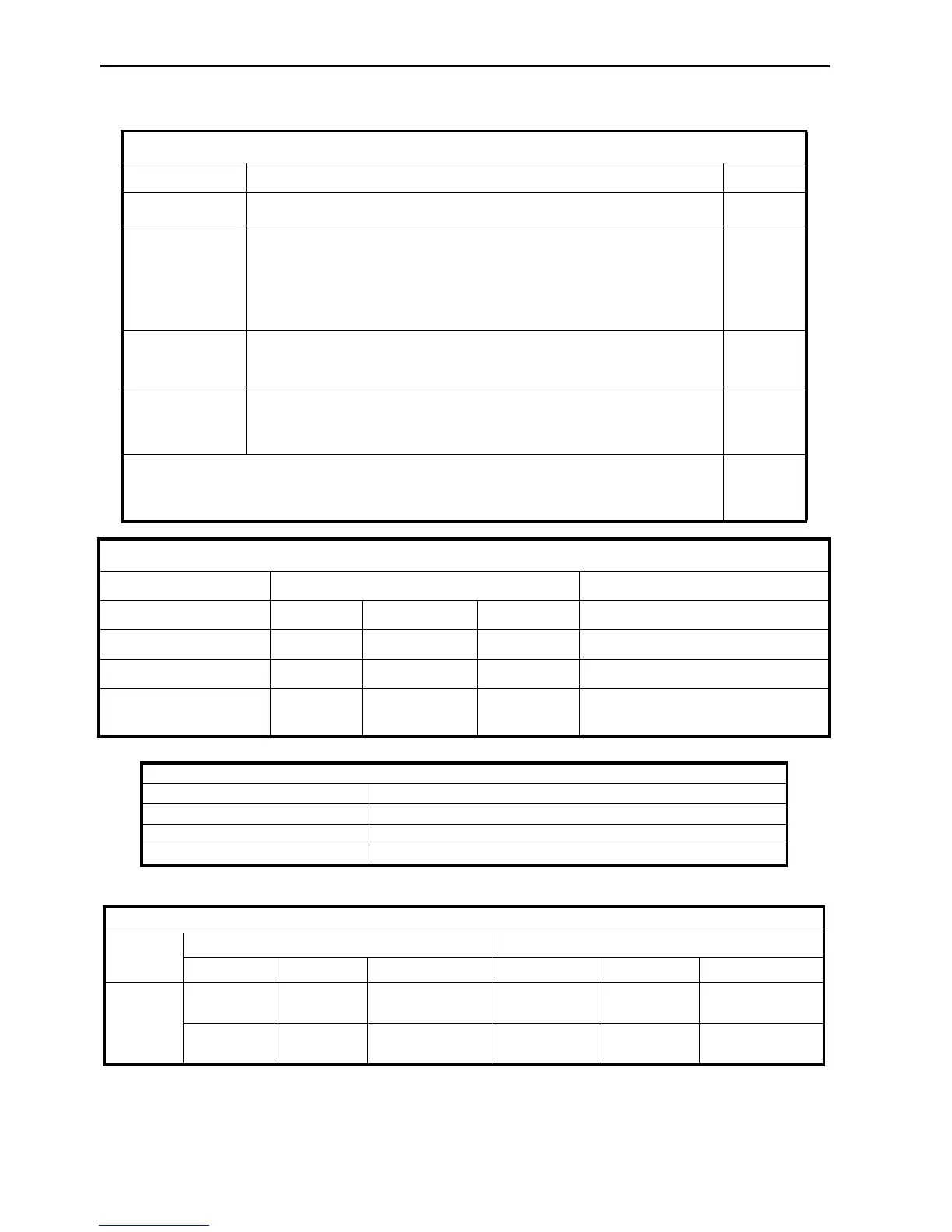

TYRE PRESSURE

Product

Front Wheel Rear Wheel

Tyre Size Tyre Type Tyre Pressure Tyre Size Tyre Type Tyre Pressure

MP493

26 x 12.00 - 12

Grassmaster 8

pr

1.37 - 1.72 bar

(20 - 25 psi)

20.00 x 10.00 - 8

Grassmaster

6 pr

1.37 - 1.72 bar

(20 - 25 psi)

26 x 12.00 - 12 Armaturf 8 pr

1.37 - 1.72 bar

(20 - 25 psi)

20.00 x 10.00 - 8 Armaturf 6pr

1.37 - 1.72 bar

(20 - 25 psi)

Loading...

Loading...