Loading...

Loading...

Do you have a question about the Janome MC400E and is the answer not in the manual?

| Type | Embroidery Machine |

|---|---|

| Embroidery Area | 7.9" x 7.9" (200mm x 200mm) |

| Built-in Designs | 160 |

| Built-in Fonts | 6 |

| Display | LCD Touch Screen |

| Connectivity | USB |

| Weight | 18.5 lbs |

| Needle Threader | Yes |

| Maximum Stitch Width | 7 mm |

| Maximum Stitch Length | 5 mm |

| Built-in Memory | Yes |

| Speed Control | Yes |

| Drop Feed | Yes |

| Free Arm | No |

| Presser Feet | Embroidery Foot |

Procedure to remove and attach the face cover.

Procedure to remove and attach the thread cutter cover.

Procedure to remove and attach the base plate.

Procedure to remove and attach the bed cover.

Procedure to remove and attach the front cover.

Procedure to remove and attach the rear cover.

Procedure to remove and attach the carriage cover.

Procedure to remove and attach the belt cover.

Adjusting needle position at the center of the needle plate hole.

Setting hook timing for ascending needle bar travel.

Setting needle eye to hook race distance.

Setting clearance between needle and rotary hook.

Ensuring smooth gear movement and limiting rotary play.

Setting needle height for "Bight" phase change.

Setting thread tension to 59-67 gram-force.

Setting tension disc to open/close correctly.

Procedure to replace the needle threader plate.

Adjusting needle threader hook position for alignment.

Setting space between needle plate and foot.

Procedure to remove and install printed circuit board A.

Procedure to remove and install printed circuit board F.

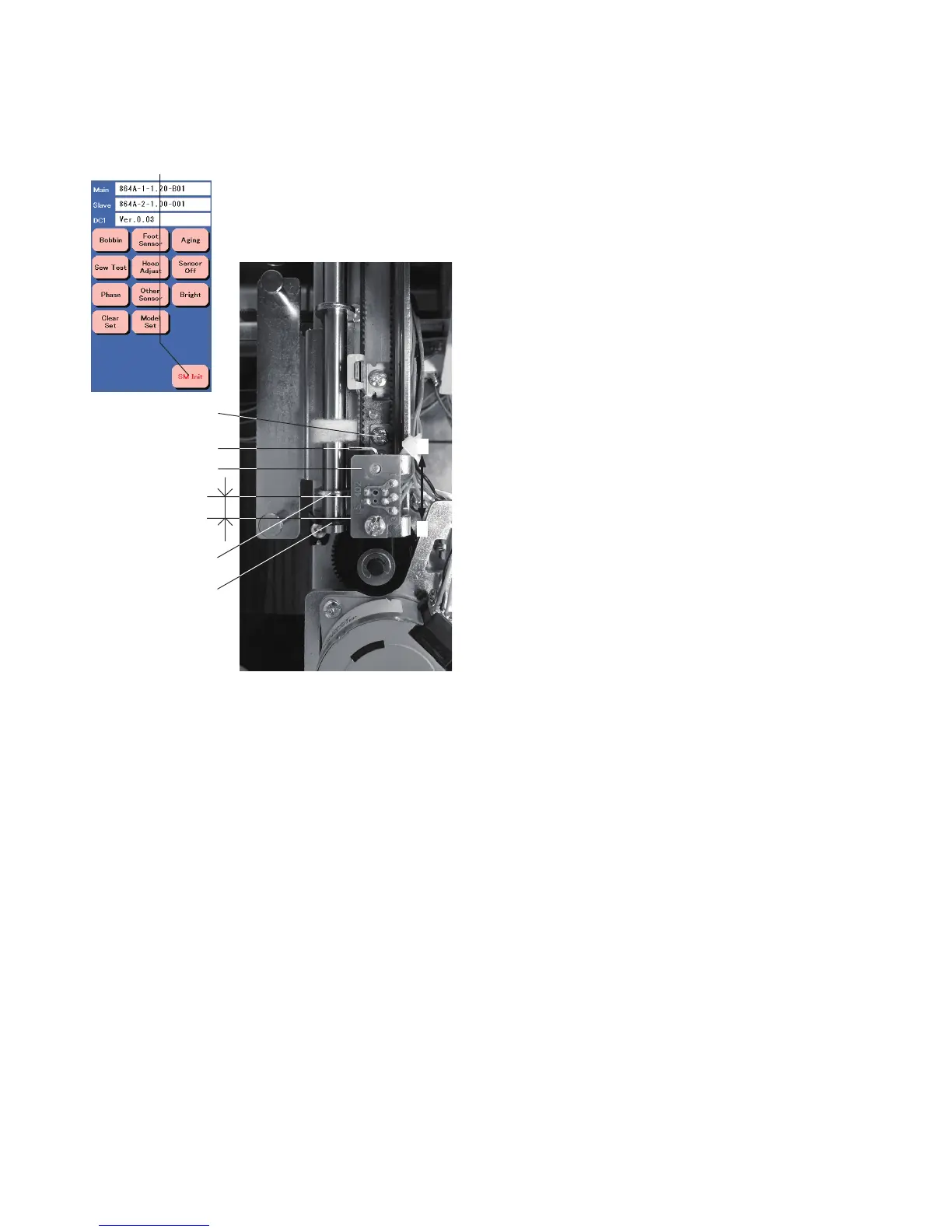

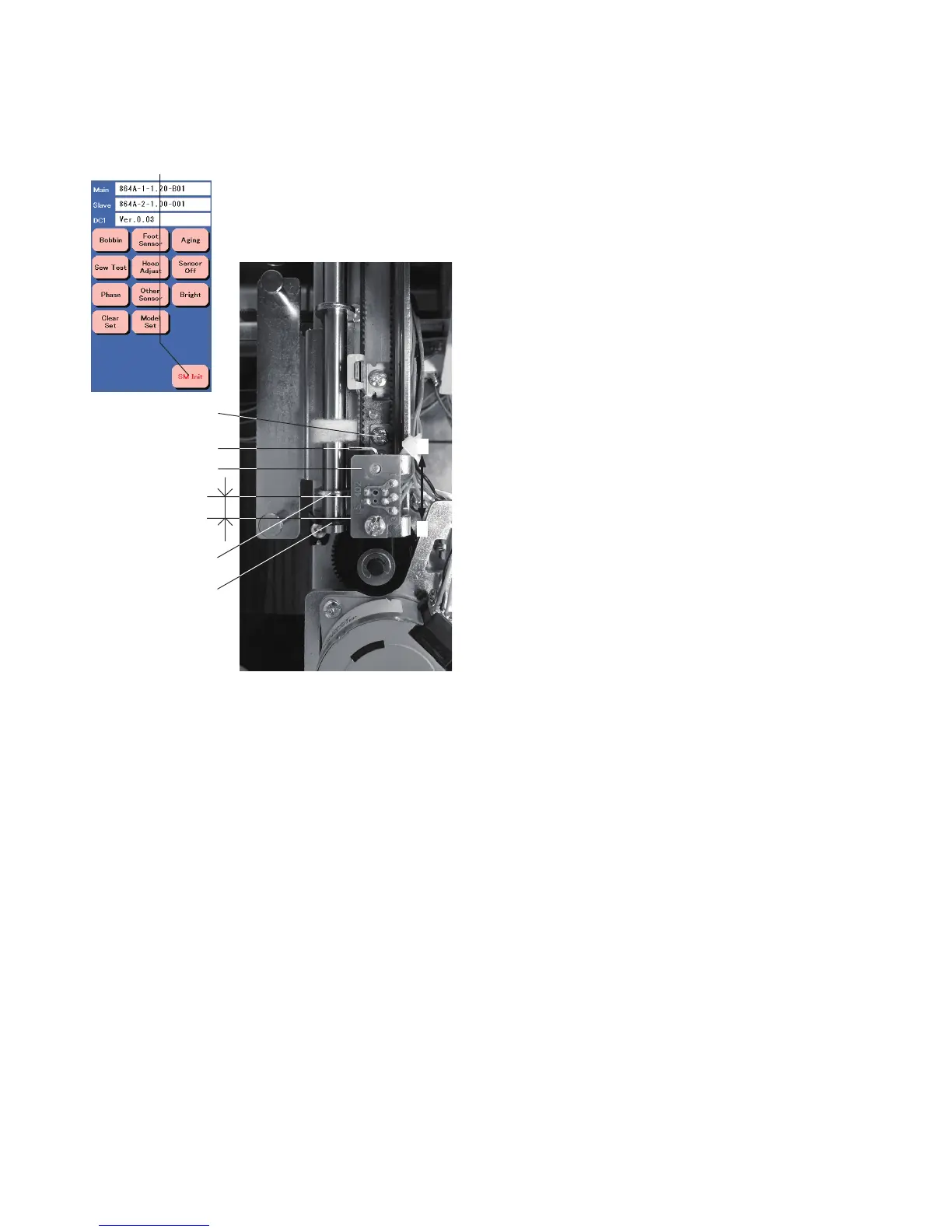

Calibrating the switch for foot position detection.

Setting distance for thread cutter plate slit and moving cutter.

Calibrating the sensor for bobbin thread levels.

Aligning hoop with the template hole.

Procedure to remove and install the carriage unit.

Setting the gap between stopper and X-carriage guide.

Setting the gap between hoop base and Y-shaft plate.

Setting distance between rail and Y-carriage edge.

Procedure to remove and install the switching power supply.

Procedure to remove and install the driving motor.

Procedure to replace gears in the X-carriage.

Oiling points for needle bar, presser bar, and take-up lever.

Oiling procedure for the oil wick.

Oiling points for the front and rear lower shaft supporters.

Oiling points for the Y-carriage.

Oiling points for the X-carriage.