15 - 2

Descriptions (cont'd)

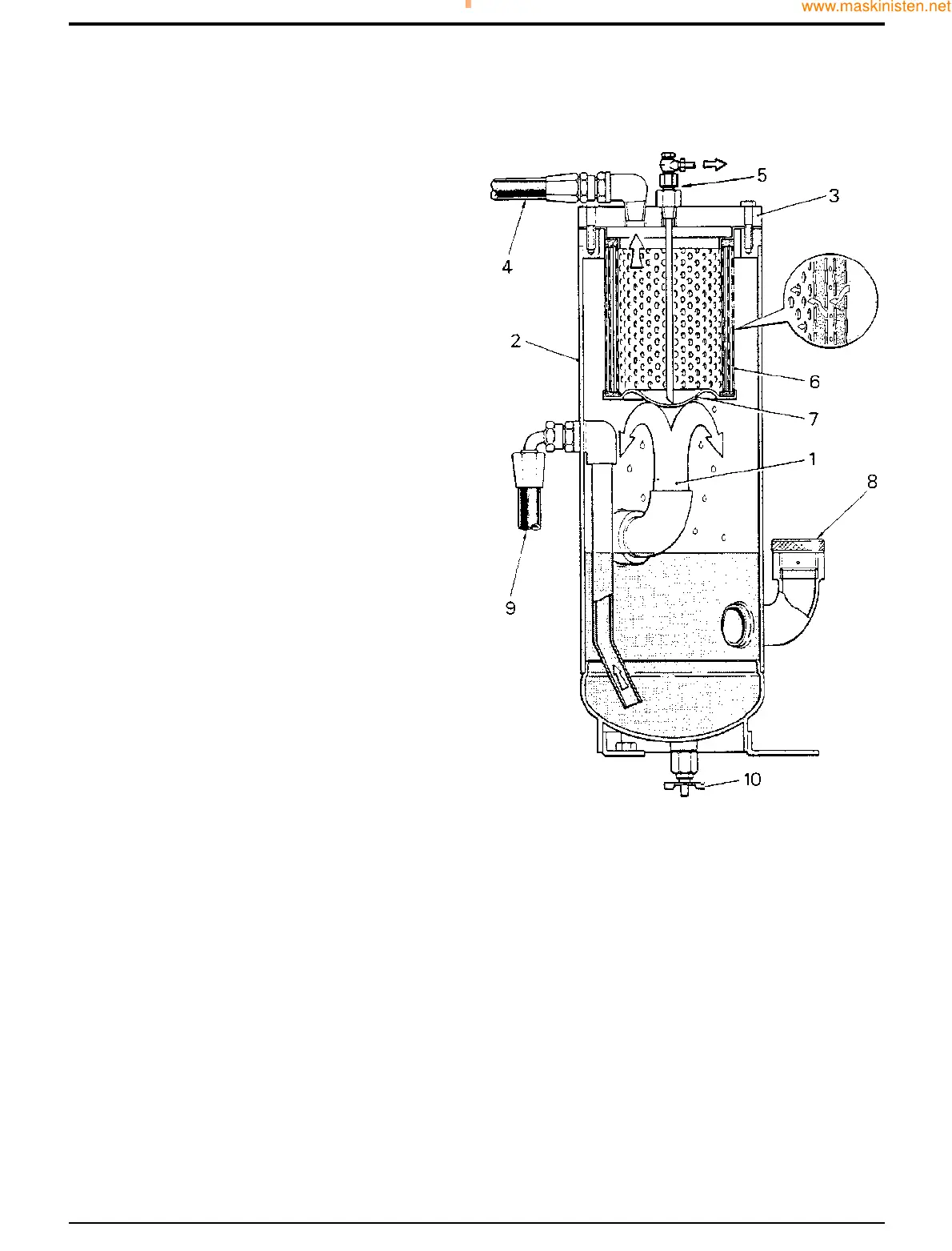

Oil Separation and Recovery

The air/oil receiver separates the oil from the air/oil mixture

after compression has taken place and acts as an oil

reservoir.

The receiver consists of a vertical steel casing 2 constructed

in accordance with the appropriate standards for fusion

welded pressure vessels and contains a separator 6.

Access to the separator is provided by cover 3. Fitted in the

cover is a temperature sensor, air pressure gauge feed, oil

scavenge tube 5 and air delivery pipe 4 terminating at the

delivery manifold. Receiver fittings include an oil filler

plug/dipstick 8, drain tap 10 and safety valve (not shown).

The air/oil mixture 1 from the compressor enters the receiver

through an angled connection which directs the mixture

against the bottom of well 7. The resulting sudden change in

speed and direction of the flow causes most of the oil to

drop out under gravity to the bottom of the casing where it

re-joins the main oil flow and is re-circulated.

The air which now holds only a small amount of fine oil mist

then flows through the separator 6 where the mist is

agglomerated into large droplets which collect in well 7.

From there the collected oil is returned via the oil scavenge

tube 5 to the compressor by differential pressure.

Component Key

Item Description

1 Air/oil mixture (from compressor)

2 Receiver casing

3 Cover

4 Air delivery pipe

5 Oil scavenge tube and restrictor

6 Separator element

7 Well

8 Oil filler/dipstick plug

9 Oil feed to cooler

10 Drain tap

Section A Attachments

9803/7130

Section A

15 - 2

Issue 1

Airmaster Compressor

S212050