20 - 1

Front and Rear Axle -

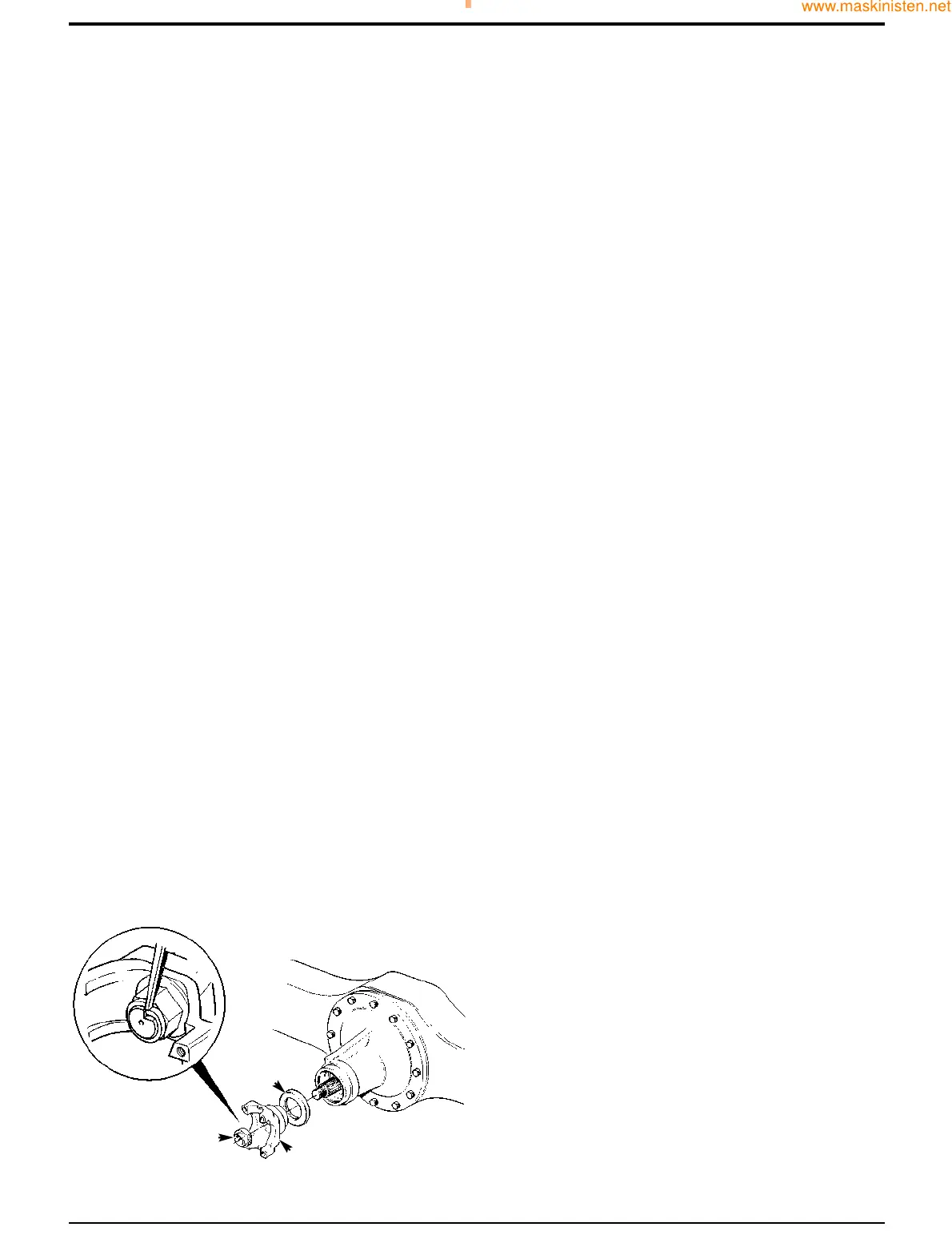

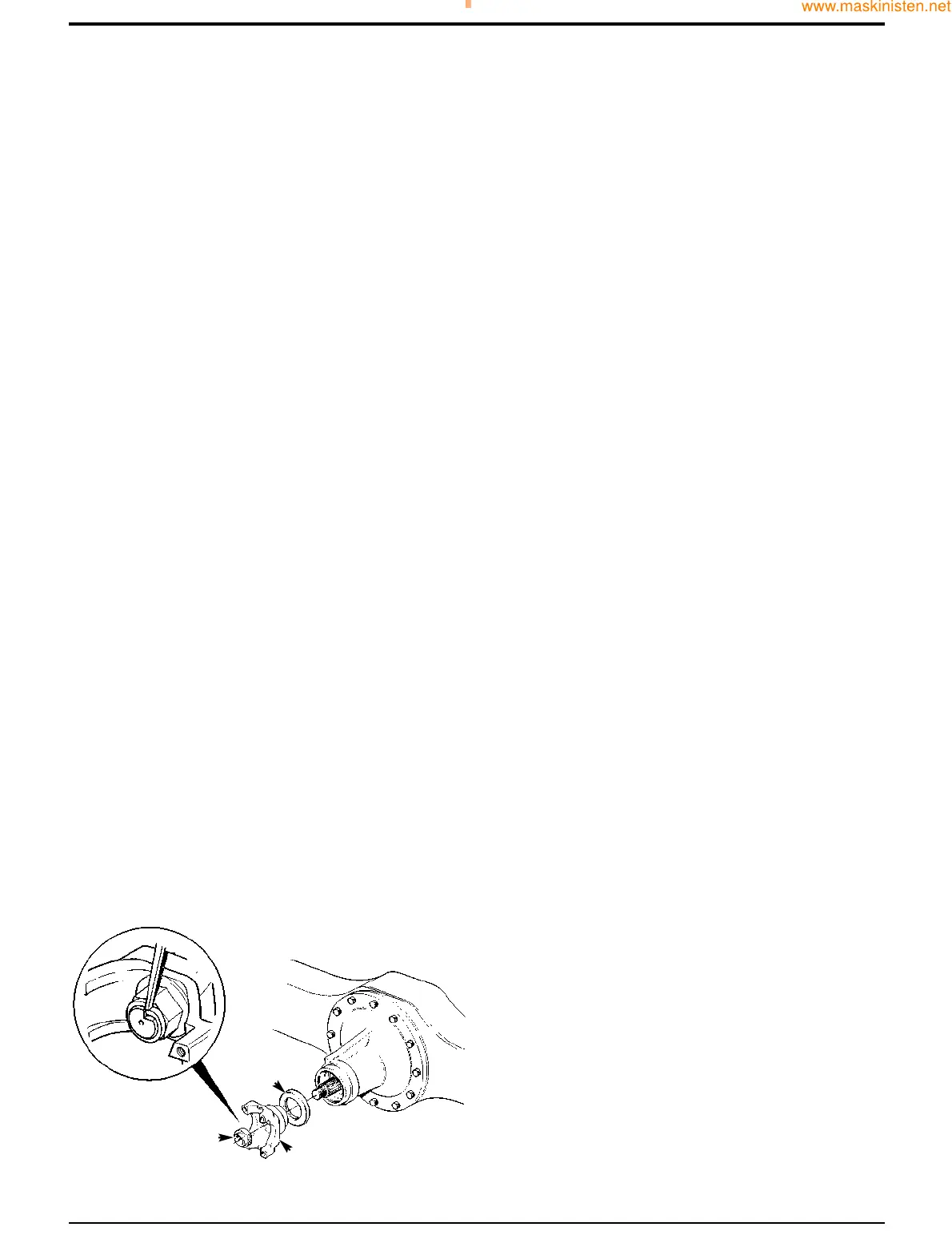

Renewing the Pinion Oil Seal

The pinion oil seal 4 may be renewed without removing the

axle from the machine.

!!

WARNING

A raised and badly supported machine can fall on you.

Position the machine on a firm, level surface before

raising one end. Ensure the other end is securely

chocked. Do not rely solely on the machine hydraulics or

jacks to support the machine when working under it.

Disconnect the battery, to prevent the engine being

started while you are beneath the machine.

GEN-001

1 Remove the roadwheels and uncouple the axle

propshaft. Measure the axle rolling torque and record

the reading.

2 Using Service Tool 892/00812, remove the drive yoke 1

together with its stake nut 2.

3 Remove the seal 4 and fit a new one. Pack between the

lips of the new seal with grease before fitting.

4 Fit the coupling yoke, and a new stake nut:

a Using Service Tool 892/00812, tighten the nut to

200 Nm (148 lbf ft; 20.4 kgf m).

b Measure the rolling torque. The reading should be

0.5 to1Nm (0.37 to 0.74lbf ft; 0.05 to 0.1kgf m)

more than that recorded in Step 1.

c Progressively torque tighten nut to achieve correct

rolling torque or a maximum of 300Nm (287 lbf ft).

Note: If the rolling torque figure (new pinion seal fitted)

exceeds the reading recorded in step 1 by 1Nm (0.74 lbf ft;

0.1 kgf m) or more, this would indicate that a collapsible

spacer has been fitted which MUST be renewed.

d Stake the nut using a square ended staking tool.

5 Refit the roadwheels and couple the propshaft.

Section F Transmission

9803/7130

Section F

20 - 1

Issue 1

Service Procedures

S380610

11

22

44

Loading...

Loading...