61 - 2

Dismantling and Assembly

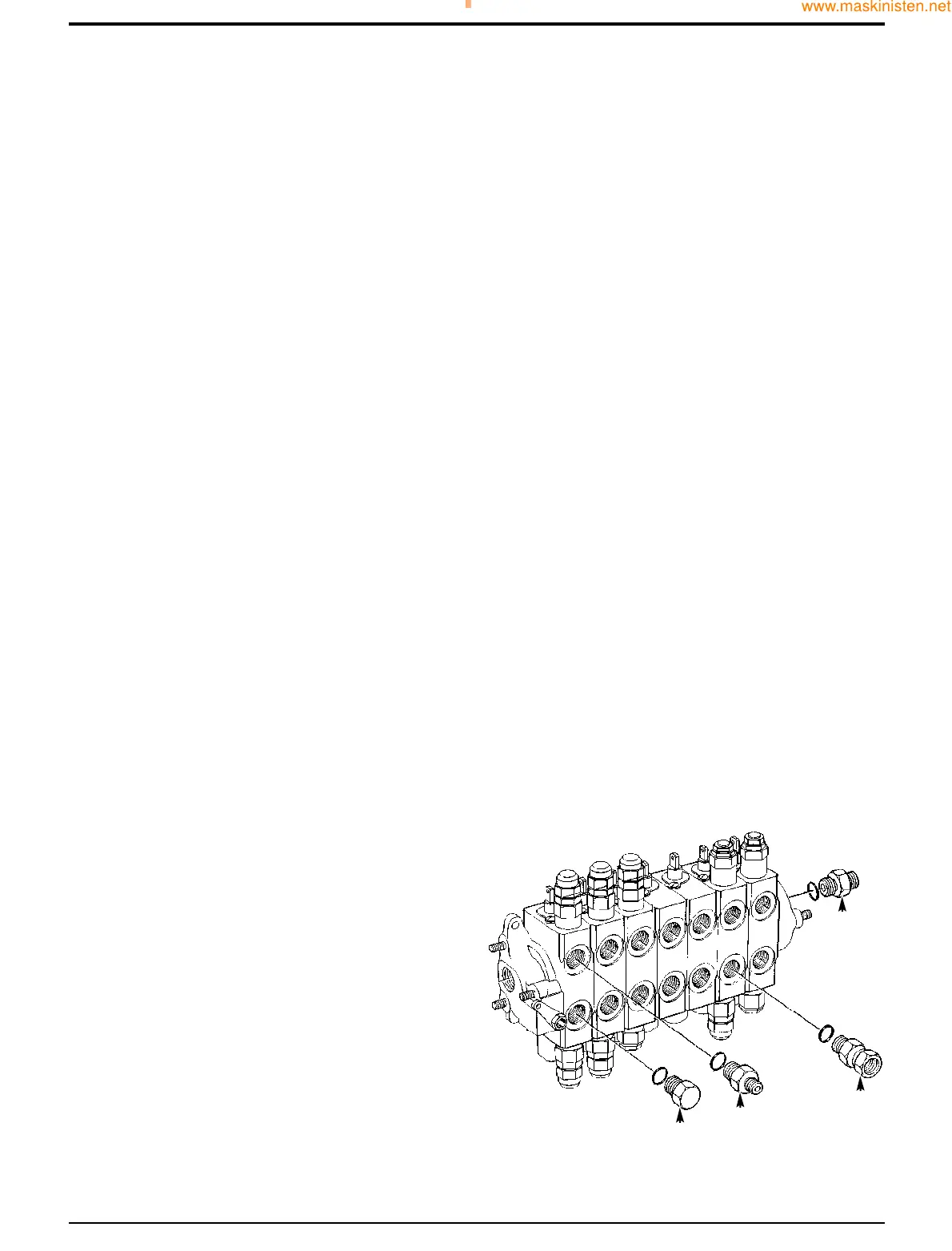

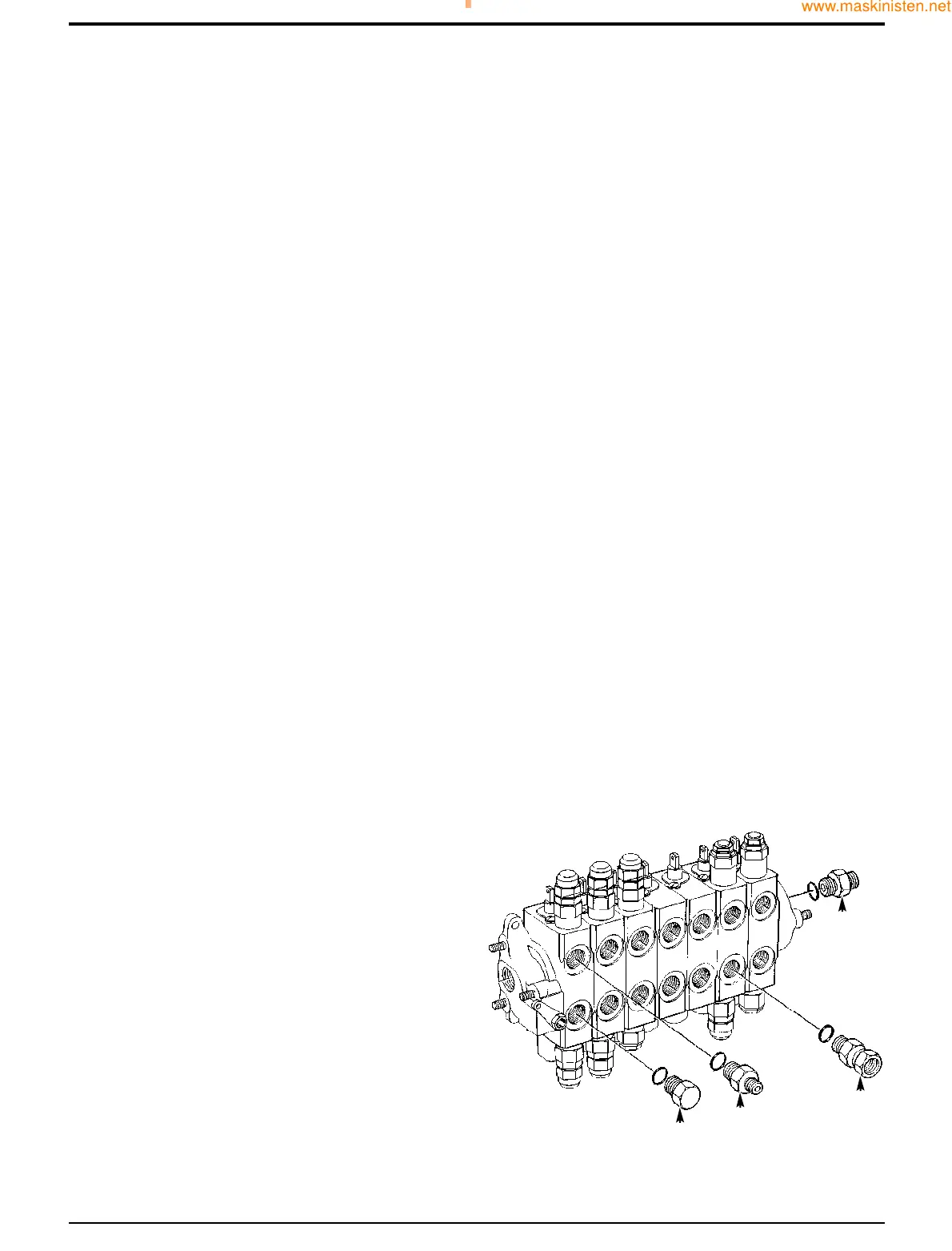

The numerical sequence shown on the illustration is

intended as a guide to dismantling.

For assembly the sequence should be reversed.

Great care should be taken when dismantling and

assembling a valve to avoid the following:-

Contamination

Damage to spools

Damage to seal grooves

Any of the above may result in possible problems with the

operation of the valve.

Dismantling

When removing 'O' Rings and seals, use an appropriatly

rounded tool that WILL NOT cause any damage to the seal

grooves.

Discard ALL 'O' Rings. DO NOT use worn or damaged

items.

Check Valves

Each of the identical load hold check valves 4R to 4W can

be removed as shown at 4W. Note only 4W shown on

illustration.

Ensure good condition of seating face on poppet 10 and on

the mating face in the valve block.

Note: Valve block adapters, types A, B, C and D are torqued

to 81 Nm (60 lbf ft; 8.3 kgf m).

Spools

Spools 4B, 4C, 4D, 4E and 4F are identical but must not be

interchanged as they are matched to their bores. Slew spool

4A is different in design from the above spools.

All spools have the same centring and sealing components

items 11 to 19 and 24 to 27.

To completely dismantle a spool, follow the sequence 11 to

19 and 24 to 27. To prevent spool rotation when turning

screw 13, hold a rod through the eye end of the spool.

Inspection

Inspect the valve components for scratches, nicks or any

other type of damage, replace with new if required.

Assembly

Renew all 'O' rings.

Lubricate new seals with JCB Hydraulic Fluid and take care

to prevent them from being damaged by the sharp edges of

the spool.

Apply JCB Threadlocker and Sealer to threads of screw 13.

Section E Hydraulics

9803/7130

Section E

61 - 2

Issue 1

Excavator Valve

S205350

DD

CC

BB

AA

Torque Settings

Item Nm kgf m lbf ft

1A 17.6 - 20.4 1.76- 2.04 13 - 15

1B 41 - 49 4.2 - 5 30 - 36

11 6.1 - 7.5 0.62 - 0.76 4.5 - 5.5

13 9.5 - 10.9 0.97 - 1.11 7 - 8

22 41 - 68 4.15 - 6.9 30 - 50

Relief Valves

Ensure that A.R.V's 4H to 4P are correctly adjusted and

fitted in their specified positions.

Torque tighten A.R.V's 4H, 4J, 4K and 4N to 41 - 68 Nm (30

- 50 lbf ft, 4.15 - 6.9 kgf m).

Torque tighten A.R.V's 4L, 4M and 4P to 41 - 68 Nm (30 - 50

lbf ft, 4.15 - 6.9 kgf m).

For relief valve dismantling and assembly procedure, refer to

Excavator Valve, Dismantling and Assembly - ARV’s.

Loading...

Loading...