17

Daily Checks (10h) Operator’s Manual Page Ref. Physical/Visual

Tyre pressure check 188-189 Physical

Wheel nuts alignment check 186-187 Visual

Tow hitch condition check 74 Visual

Windscreen washer fluid level check/refill 160 Visual

Oil level check 172-173 Physical

Fuel level check 64 Visual

Coolant quality/level check 218 Visual

Coolant or oil leaks check 172 Visual

Park brake – operation check 184 Physical

Oil level check 172-173 Physical

Service brake operation check 184-185 Physical

Park brake operation check 184 Physical

Brake pressure warning operation check 62 & 171 Physical

Controls isolation safety system operation check 171 Physical

Quickhitch safety system operation check 171 Physical

Neutral start safety system operation check

171

Physical

Overload warning system operation check

171

Physical

Weekly Checks (50h) Check

Engine filter/sedimenter drain/clean

173

Physical

Fuel tank – water & sediment drain

178

Physical

Primary fuel filter drain/clean

181

Physical

Main fuel filter drain/clean

181

Physical

Fuel filler cap check/clean

179

Physical

Radiator clean/check

108 & 183

Physical

Pivot & links lubricate

165

Physical

Battery inspect

193

Visual

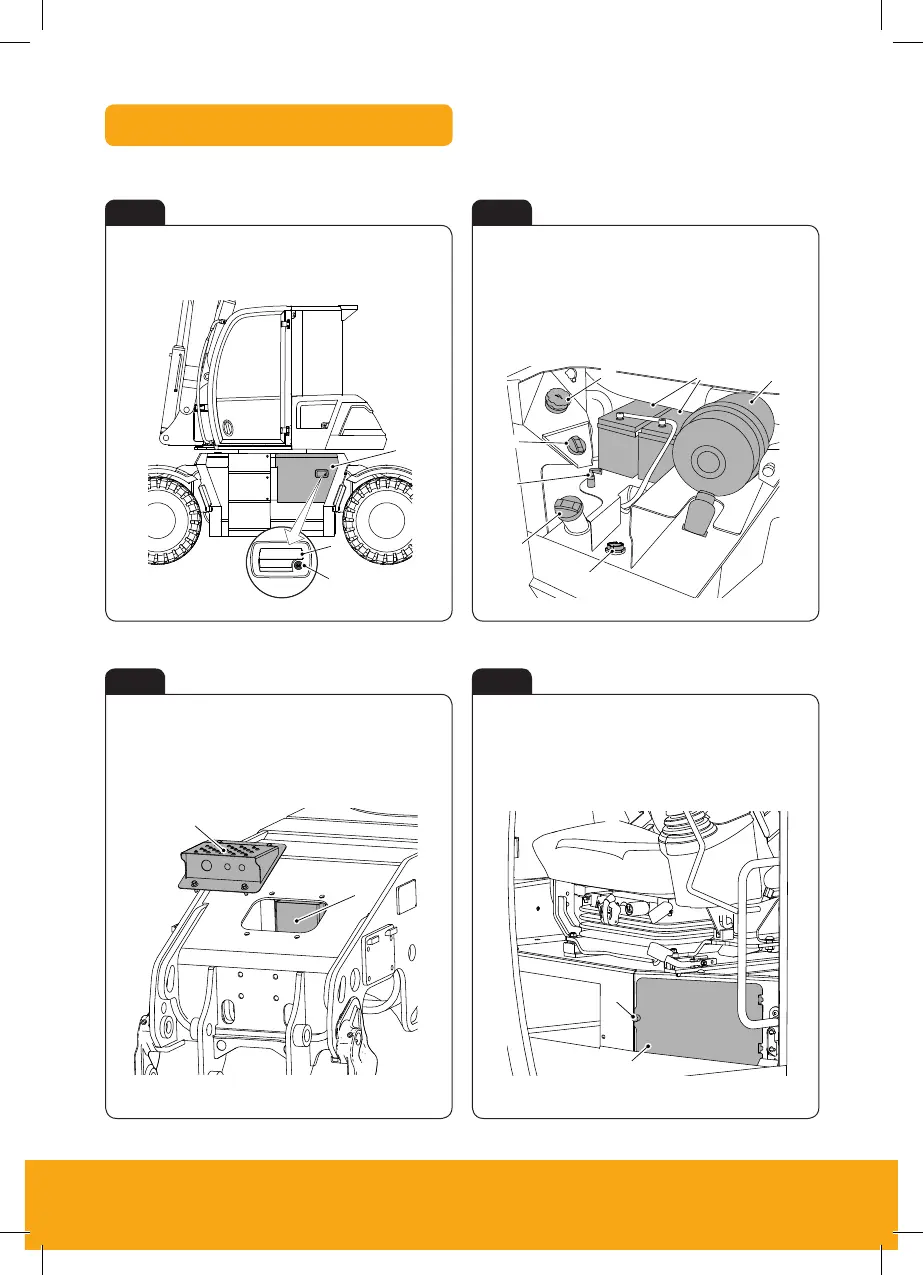

Access Covers

Fig 17

Fig 19

Fig 18

Fig 20

Maintenance

Electrical System

204 9831/3350-2 204

The electrical circuits are protected by fuses. If a fuse blows, find out why before a new one is installed. For

more information on the individual fuses. Refer to: Fuses (Page 256).

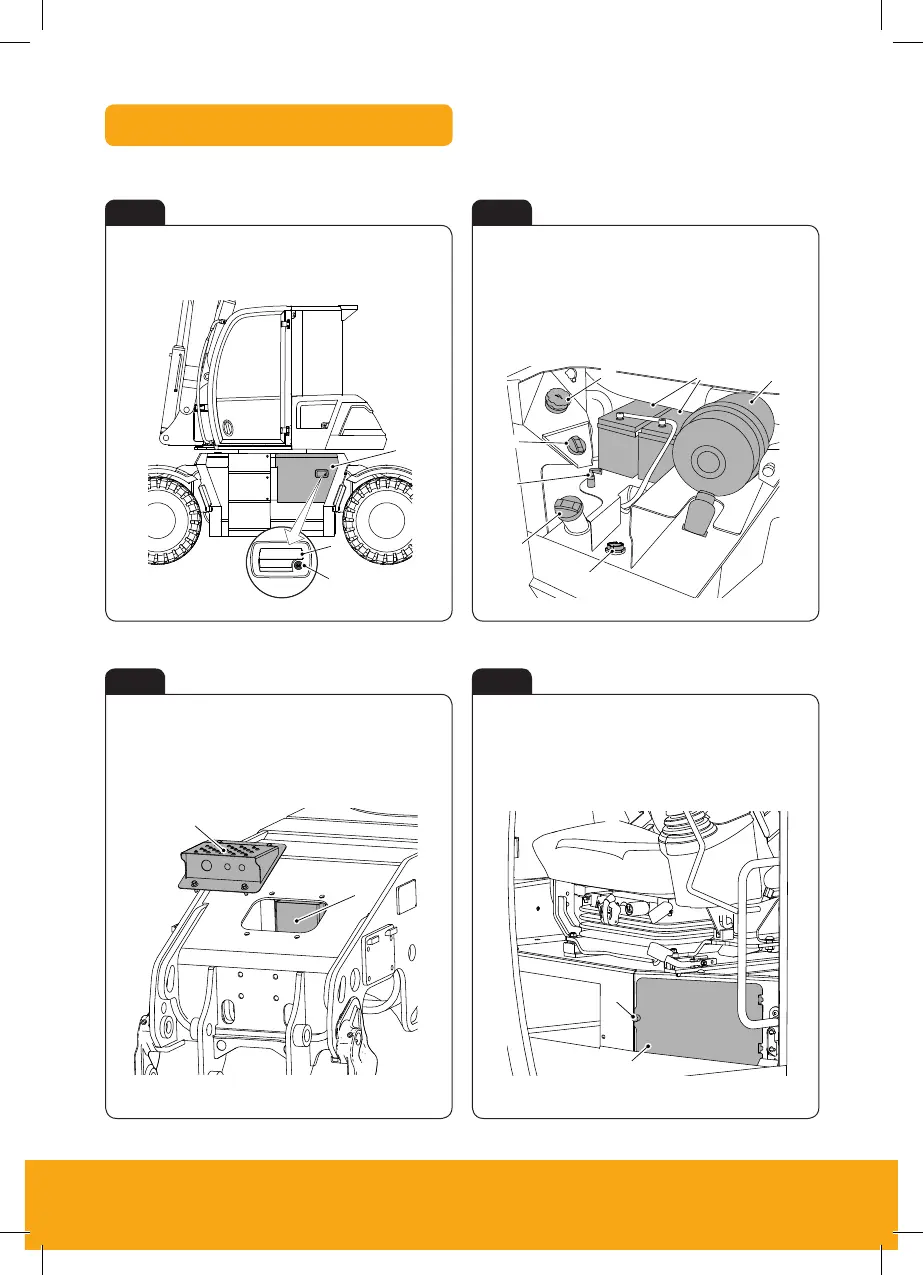

Upper Fuses

The fuses are installed in the cab below the operator seat. Remove the thumb screw and open the cover to

get access to the fuses.

Figure 138.

A Cover B Thumb screw

Lower Fuses

The fuses are installed under the tread plate on the front of the chassis. Remove the cover to get access to

the fuses.

Figure 139.

B

A

A Tread plate B Cover

Battery Bay Main Fuse

The main fuse is installed at the back of the battery bay.

Maintenance

Electrical System

204 9831/3350-2 204

The electrical circuits are protected by fuses. If a fuse blows, find out why before a new one is installed. For

more information on the individual fuses. Refer to: Fuses (Page 256).

Upper Fuses

The fuses are installed in the cab below the operator seat. Remove the thumb screw and open the cover to

get access to the fuses.

Figure 138.

B

A Cover B Thumb screw

Lower Fuses

The fuses are installed under the tread plate on the front of the chassis. Remove the cover to get access to

the fuses.

Figure 139.

A Tread plate B Cover

Battery Bay Main Fuse

The main fuse is installed at the back of the battery bay.

A Cover B Handle C Lock

A Tread plate

B Cover (lower fuses)

A Air filter

B Batteries

C Hydraulic oil fill

D DEF fill

E Isolator

F Diesel fill

G Mechanical fuel

gauge

A Cover (upper fuses)

B Thumb screw

A

A

B

B

Maintenance

Service Points

166 9831/3350-2 166

Service Points

General

Figure 118.

A Cooling pack B Engine fuel filter

C Engine oil filter D Engine oil dipstick

E Coolant expansion bottle F Fuel filter/water separator

G Crank case ventilation filter H Engine oil filler cap

Figure 119.

D

C

A

E

G

B

A Fuel filter cap B DEF (Diesel Exhaust Fluid) filler cap

C Battery isolator D Hydraulic oil filler cap

E Battery F Air filter

A

B

D

E

F

G

C

Maintenance

Access Apertures

169 9831/3350-2 169

Access Apertures

General

When moved to their maintenance position, the access panels give you access to parts or areas of the machine

that are not required during machine operation.

Before you operate the machine, make sure that all of the access panels are correctly in their closed or installed

positions.

Battery Cover

Open

1. Make the machine safe.

Refer to: Maintenance Position (Excavator Arm Lowered) (Page 165).

2. Use the ignition key to unlock the cover.

3. Pull the handle to release the latch.

4. Open the cover until it latches in position.

Figure 123.

A

B

C

A Cover B Handle

C Lock

Close

1. To release the latch pull it up.

2. Close the cover.

3. Make sure the cover is closed correctly.

4. Use the ignition key to lock the cover.

A

B

C

Battery Cover

Fuses

Loading...

Loading...