Loading...

Loading...

Do you have a question about the jcb Hydradig 110W and is the answer not in the manual?

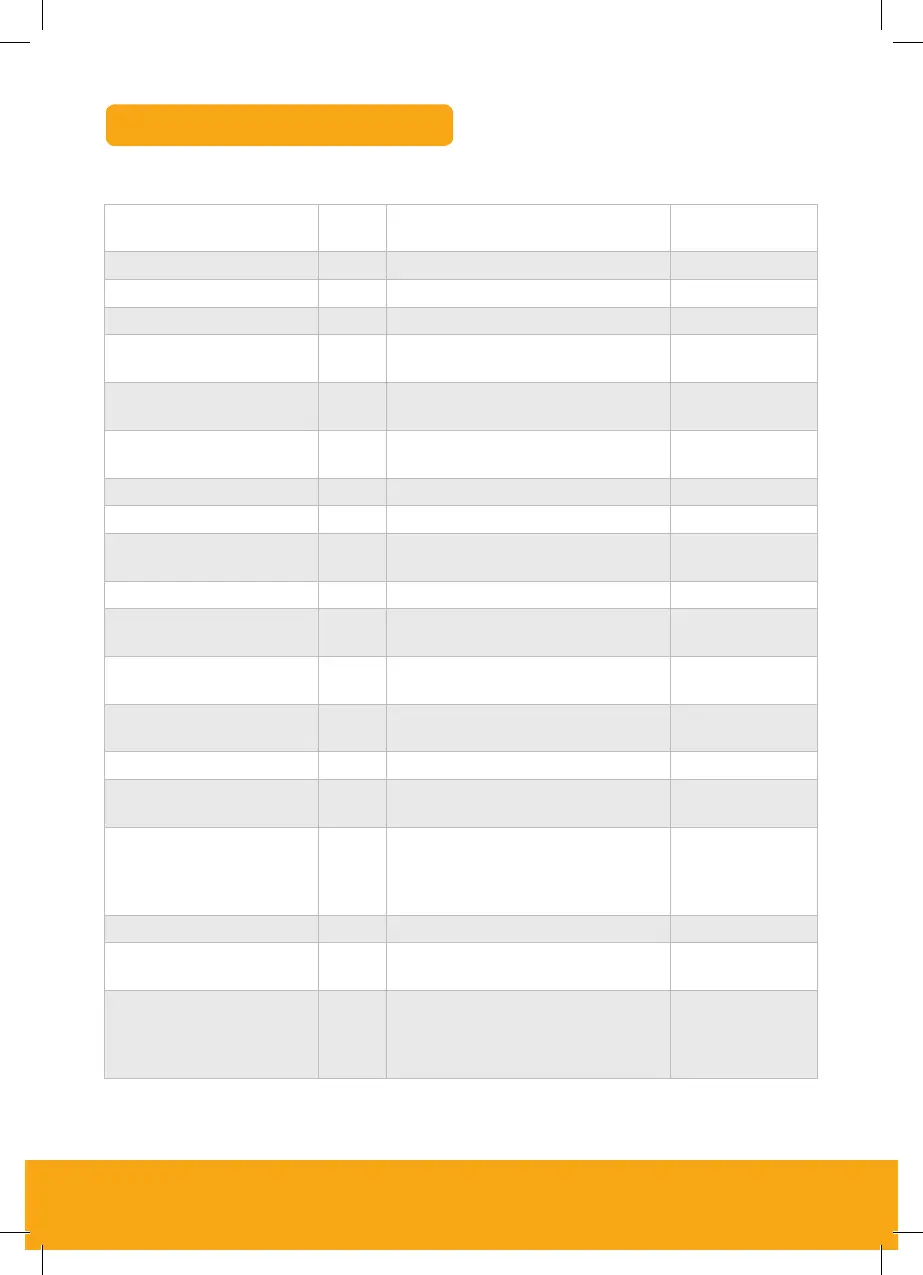

| Brand | jcb |

|---|---|

| Model | Hydradig 110W |

| Category | Excavators |

| Language | English |

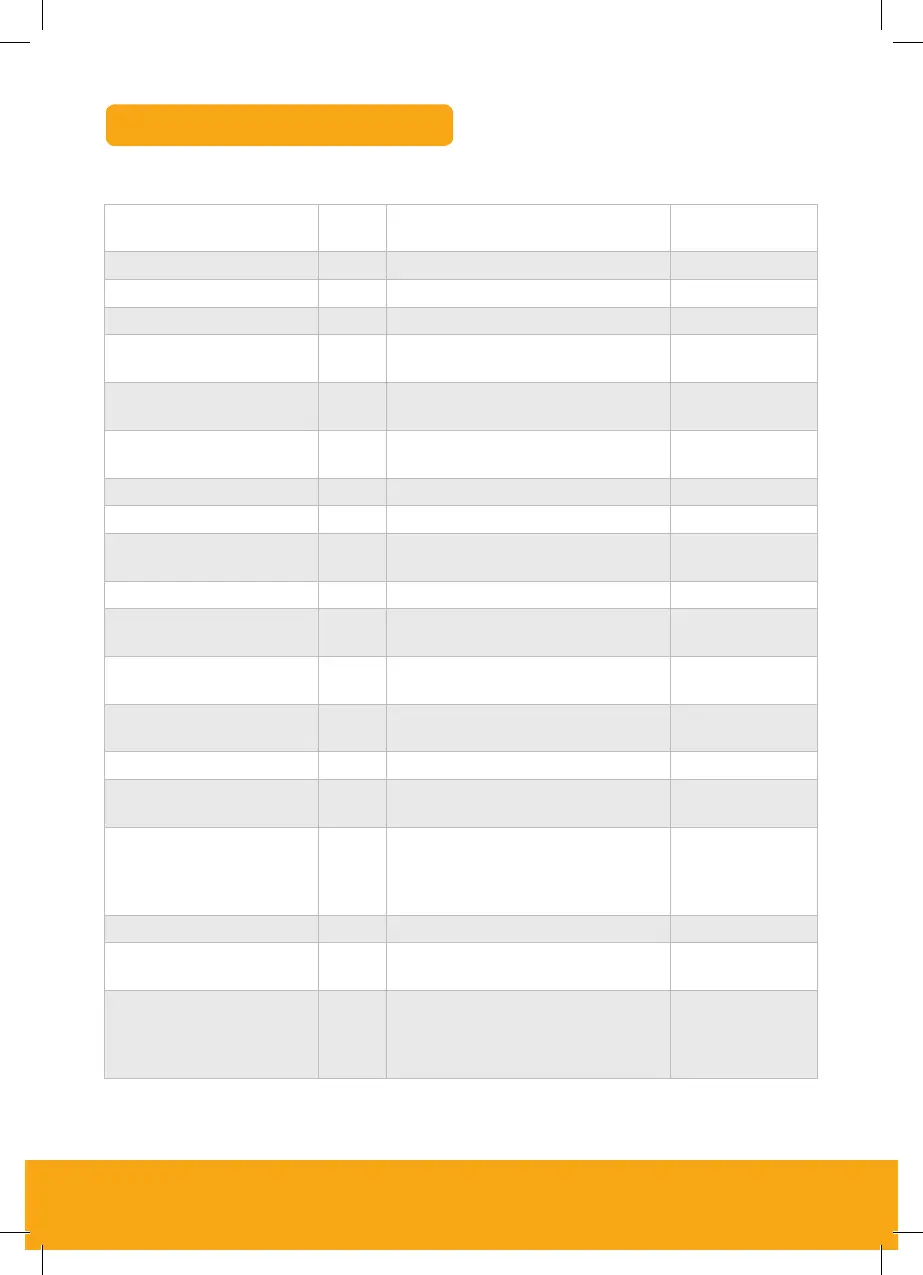

Details starting the machine, lowering the arm rest, and preparing to drive.

Outlines the process for unlocking standard attachments using the quick hitch system.

Describes procedures for specialised attachments, including crowd override and removal.

Details parking, applying brakes, securing the machine, and exiting the cabin safely.

Explains the procedure for auxiliary venting and the meaning of helmet indicators for safety.

Addresses common problems like steer option selection, highway mode, and stabiliser function.

Covers machine startup failures and the meaning of audible buzzers during operation.

Explains reasons why hydraulics might not activate, including side pod and mode settings.

Explains axle lock behaviour and the overspeed warning display and de-rate function.

Addresses issues with travel speed limitations and the operation of the quick hitch system.

Details enabling the Hand Held Tool Circuit and the meaning of auto axle lock for roading.