22

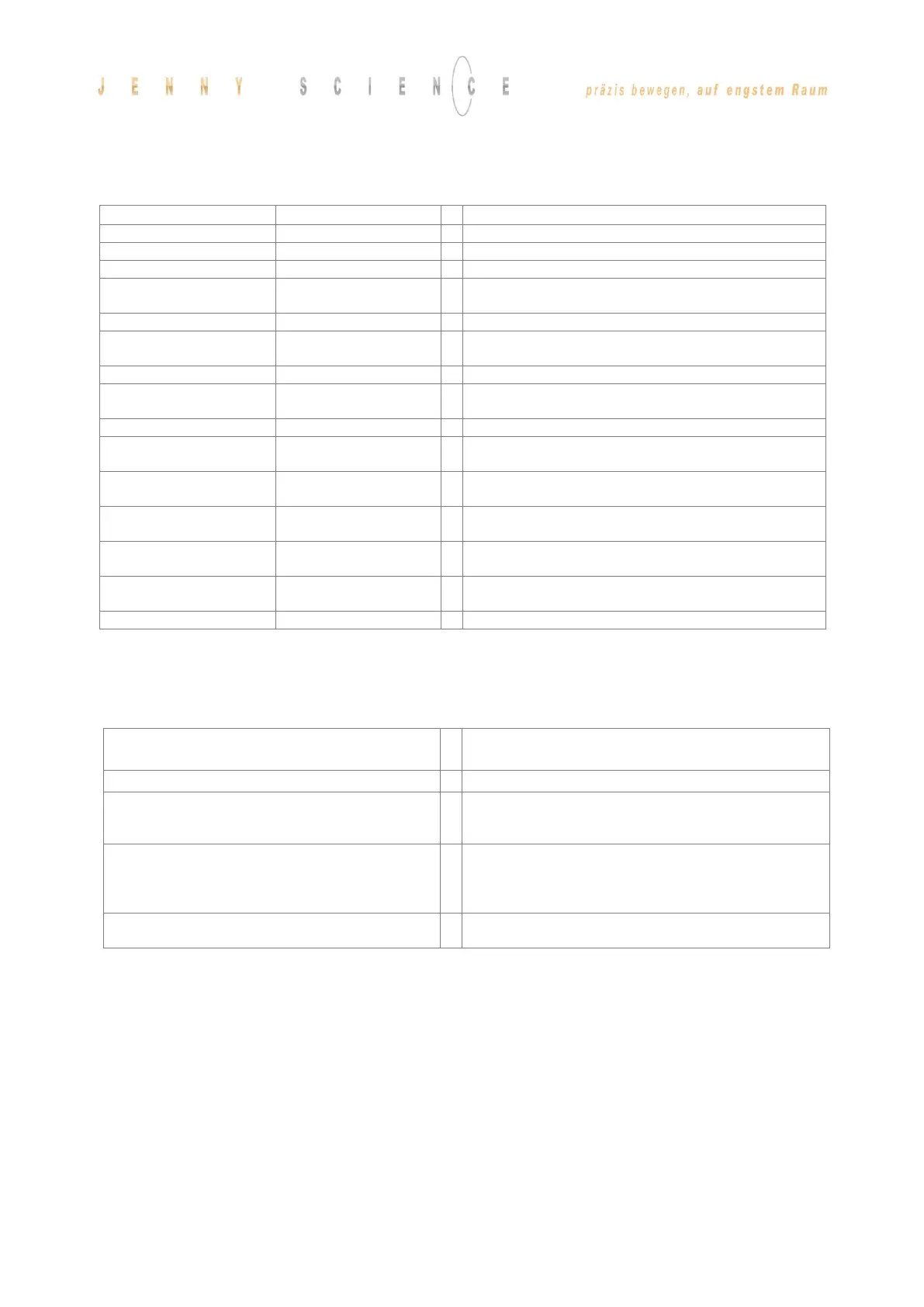

5.2.4 Encoder and Hall Signals

Together, for encoder and hall 0V supply, only 1 pin

150 mA for encoder supply

Pull up 2,7kΩ to 5V, differential input 26LS32

Middle level: pull up 2,7kΩ to 5V, Pull down 2,2kΩ,

differential input 26LS32, 330Ω internal between Pin3/4

Pull up 2,7kΩ to 5V, differential input 26LS32

Middle level: pull up 2,7kΩ to 5V, pull down 2,2kΩ,

differential input 26LS32, 330 Ω internal between Pin5/6

Pull up 2,7kΩ to 5V, differential input 26LS32

Middle level: pull up 2,7kΩ to 5V, pull down 2,2kΩ,

differential input 26LS32, 330 Ω E internal between Pin7/8

Pull up 2,7kΩ to 5V, differential input 26LS32

Middle level: Pull up 2,7kΩ to 5V, pull down 2,2kΩ,

differential input 26LS32

Pull up 2,7kΩ to 5V, differential input 26LS32 / over

temperature signal motor

Middle level: Pull up 2,7kΩ to 5V, Pull down 2,2kΩ, differential

input 26LS32

Pull up 2,7kΩ auf 5V, differential input 26LS32 /

I2C clock signal

Middle level: Pull up 2,7kΩ to 5V, pull down 2,2kΩ, differential

input 26LS32

5V, 150 mA / I2C data signal

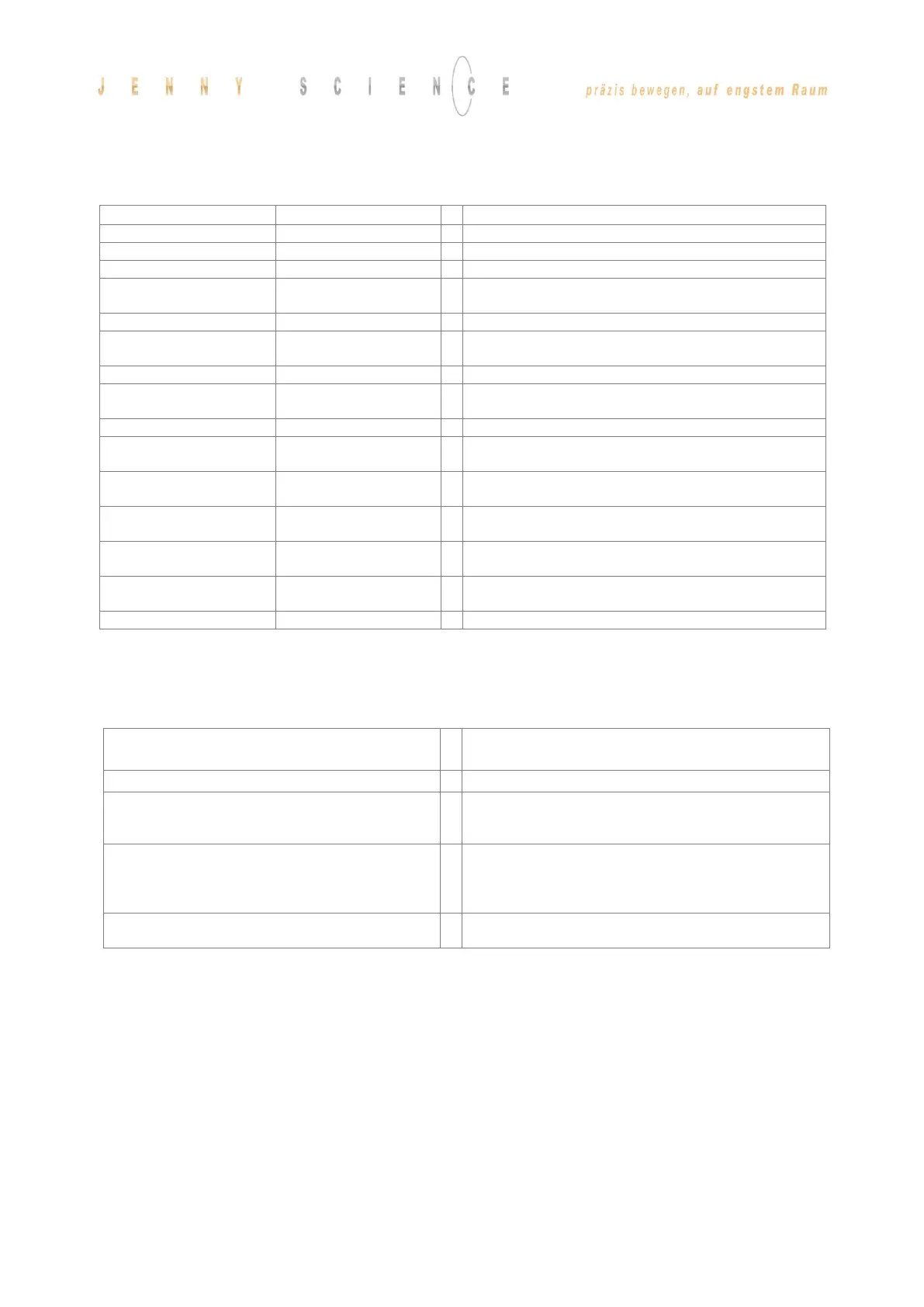

5.2.5 Definition of Rotating Direction for Servo

Motors

Sight on front surface motor shaft, turn the shaft clockwise,

the meter has to count upwards

Switch encoder A/B

Switch +/- motor power

Switch rotating direction for DC brush type servo motors

Switch encoder A/B

Switch hall1 with hall3

Switch winding-phase 1 and phase 2

Switch rotating direction for 3phase brushless servo motors

Phase 1 to phase 2, 2 to 3 and 3 to 1

Hall 1 to hall2, 2 to 3 and 3 to 1

Switch phase connection for brushless servo motors without

change of rotating direction

Loading...

Loading...