– 22 –

4-8. Intermediate presser height

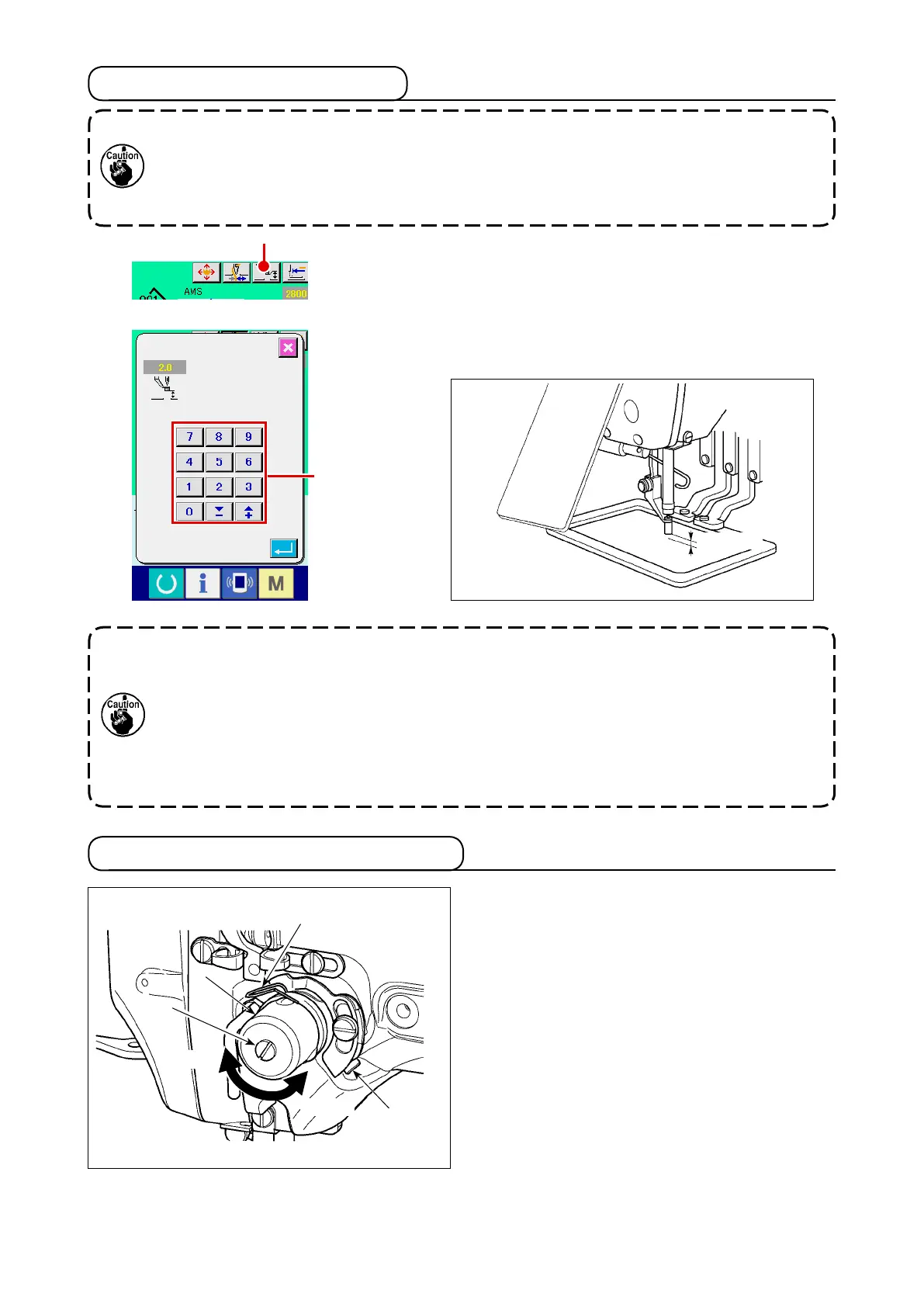

Press INTERMEDIATE PRESSER SETTING button

A

and ad-

just with TEN keys

B

so that the clearance between the bottom

end of intermediate presser and the cloth is 0.5 mm (thickness

of thread used).

1. Setting range of the intermediate presser is up to the standard of 3.5 mm.

However, when using DP X 17 needle for H type or the like, the setting range can be

changed up to max. 7 mm with memory switch U112.

2. When increasing the height of intermediate presser or making the needle size thicker,

conrm the clearance between the wiper and the components. Wiper cannot be used

unless the clearance is secured. In this case, turn OFF the wiper switch, or change the

set value of memory switch U105.

1. When raising the intermediate presser height, turn the pulley by hand to lower the needle

bar, and conrm that the needle bar does not interfere with the intermediate presser. (When

using DP X 5 needle, use the sewing machine with the height of 3.5 mm or less.)

2. Take care not to get your hands and ngers caught in the feeding frame or intermediate

presser.

A

B

0.5 mm

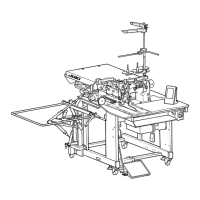

4-9. Adjusting the thread take-up spring

1) Adjusting the stroke

Loosen setscrew

2

, and turn thread tension asm.

3

.

Turning it clockwise will increase the moving

amount and the thread drawing amount will

increase.

2) Adjusting the pressure

To change the pressure of the thread take-

up spring

1

, insert a thin screwdriver into the

slot of thread tension post

4

while screw

2

is

tightened, and turn it. Turning it clockwise will

increase the pressure of the thread take-up

spring. Turning it counterclockwise will de-

crease the pressure.

2

1

4

3

Decrease

Increase