– 92 –

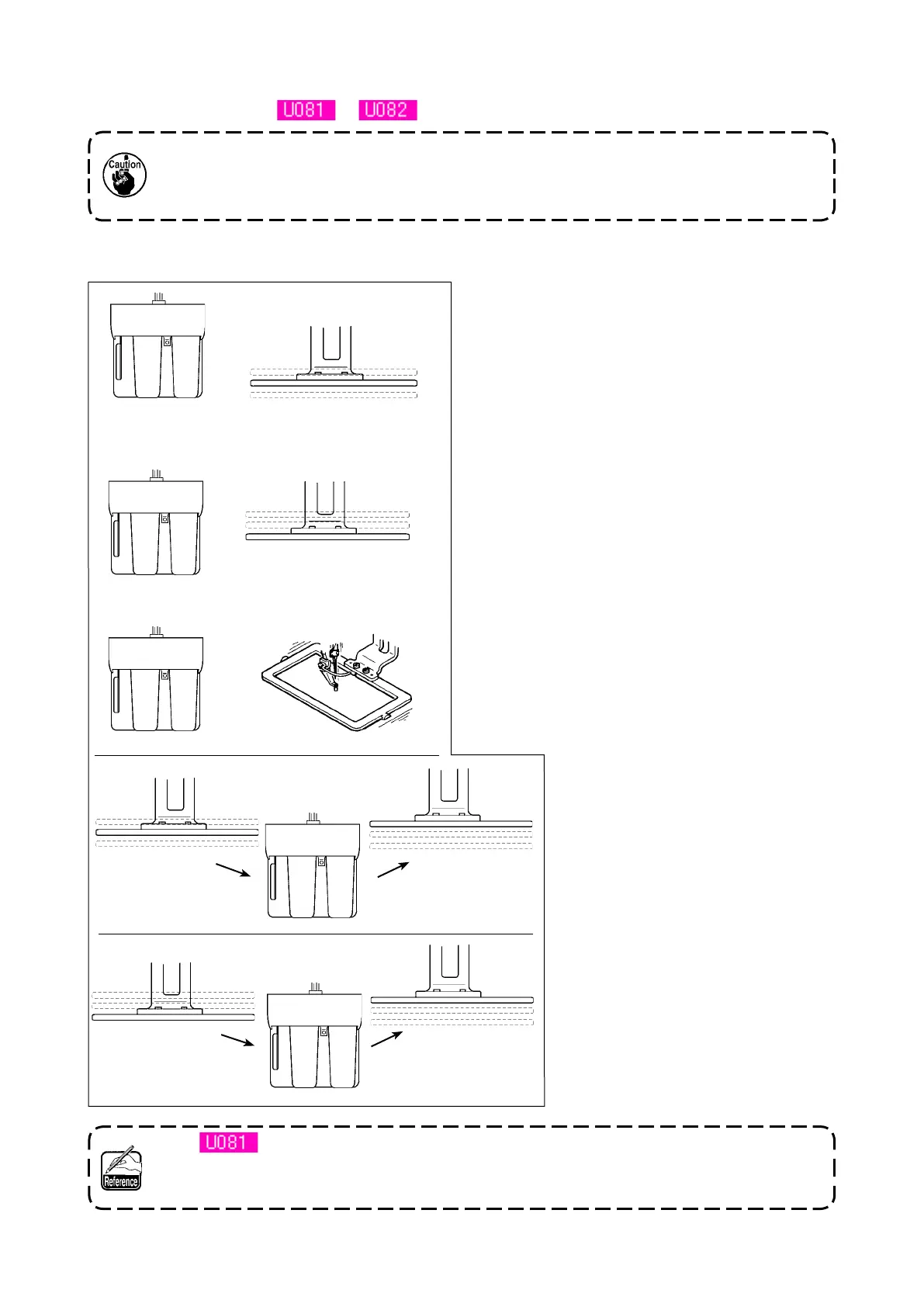

(3) Motion of 2-step stroke function

By setting memory switch or , Motion of pedal or presser can be selected.

1. In case of pneumatic type presser, the height of intermediate position changes by ad-

justing the air pressure and speed controller of the sewing machine.

2. Start of sewing with left pedal becomes effective when 0.3 seconds pass after the press-

er moved to the lowest position.

1

When depressing 1st step of the intermediate

pedal, the presser stops at the intermediate

position.

2

When further depressing 2nd step in the

state that 1st step of the intermediate pedal is

depressed, the presser comes down to the bot-

tom position.

3

When the left lever is pressed with the presser

at the bottom, sewing starts.

4

When depressing 1st step of the

intermediate pedal again in the

state that the presser is in the

intermediate position, the presser

goes up to the top.

5

When depressing the intermedi

-

ate pedal again in the state that

the presser is in the bottom posi-

tion, the presser goes up to the

top.

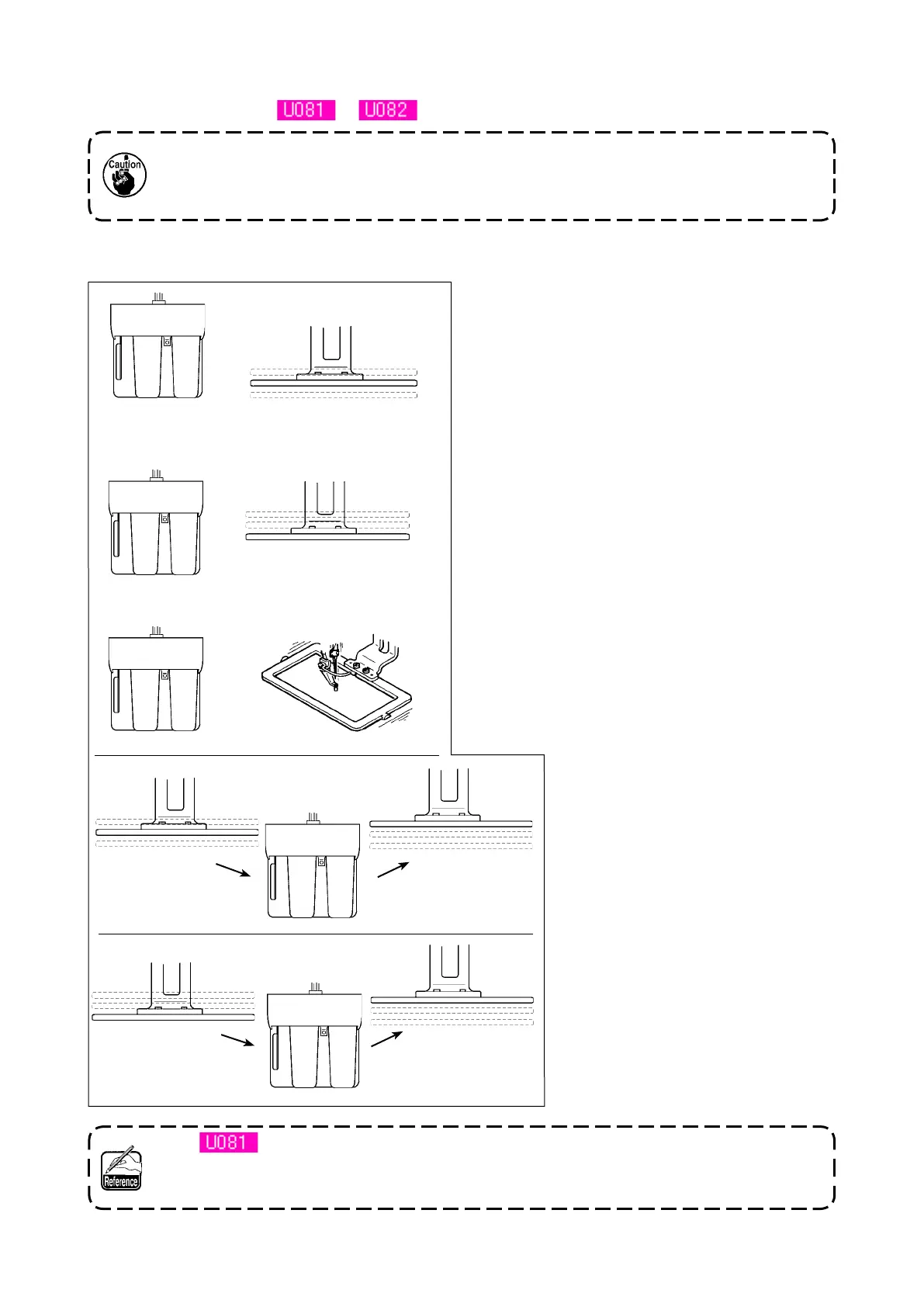

[ When solid presser 2-step stroke is selected (PK-47 is used. ]

When is set to 9 (solid presser 2-step stroke) with the right/left separated press-

ers installed, the right/left pressers are driven up and down at the same time and the same

control as that of the solid presser can be also performed.

d

d

d

d

d

d

d

u u

Loading...

Loading...