Operation manualⅠ

3− 1

Chapter 3 Various Processes During PWB

Production

This Chapter describes how to handle main errors that will occur during PWB production

and a component run-out error.

3.1 When components run out (If the check box “Stop system when

components run out” is checked on the “Operation option” screen)

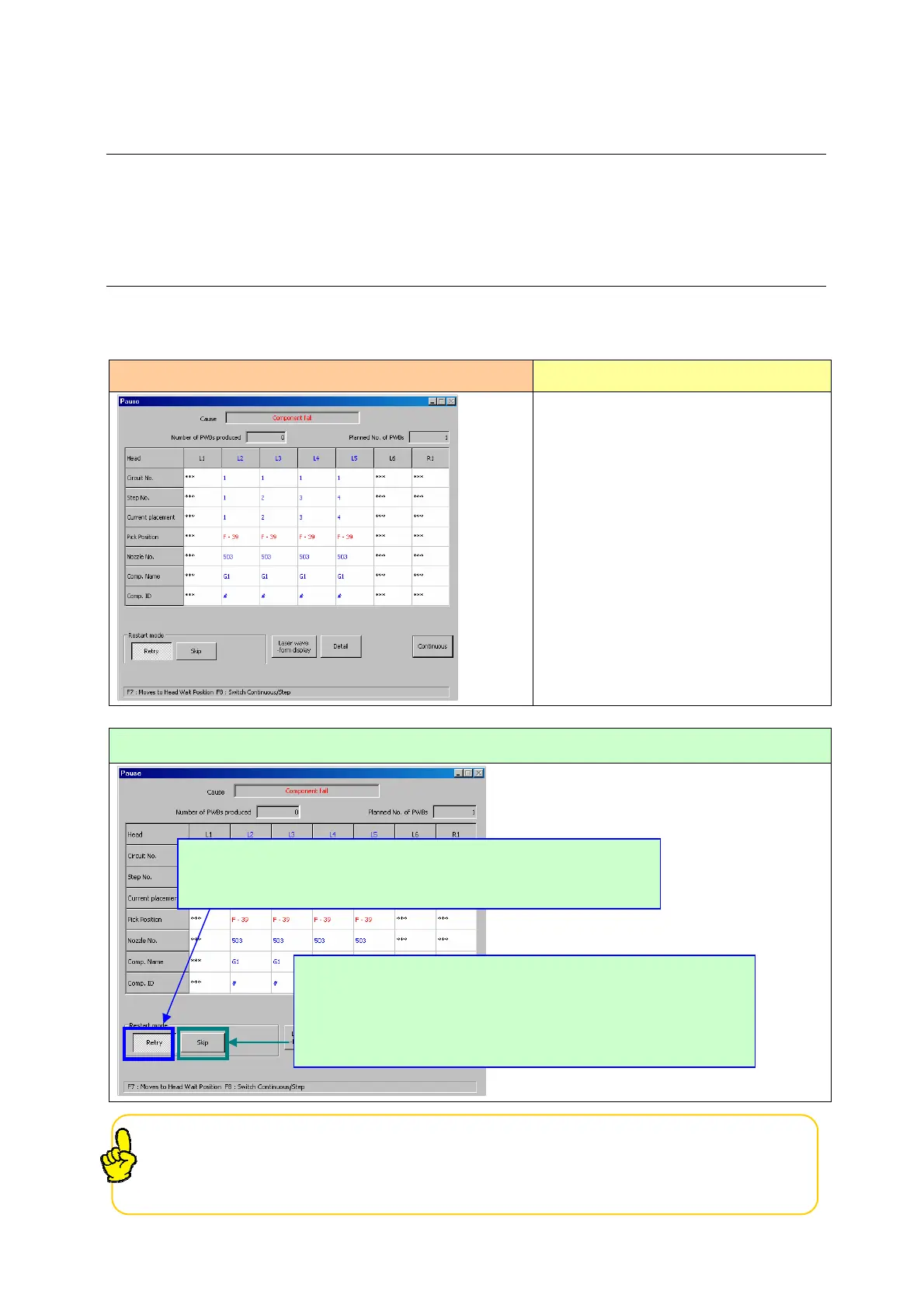

Immediately after components run out, the following screen appears and the machine

stops temporarily.

Error screen Causes of the error

① The stocked components run out.

② The machine failed to pick up a

component.

(Due to jammed peel-off tape or a

pick-up position error caused by

defective tape feeding)

How to handle an error

When you press the <CAMERA> button of the HOD while the machine stops because

components run out, you can recheck the pick-up position where a component run-out

error occurred. If a component pick-up error is serious, perform a teaching operation

again.

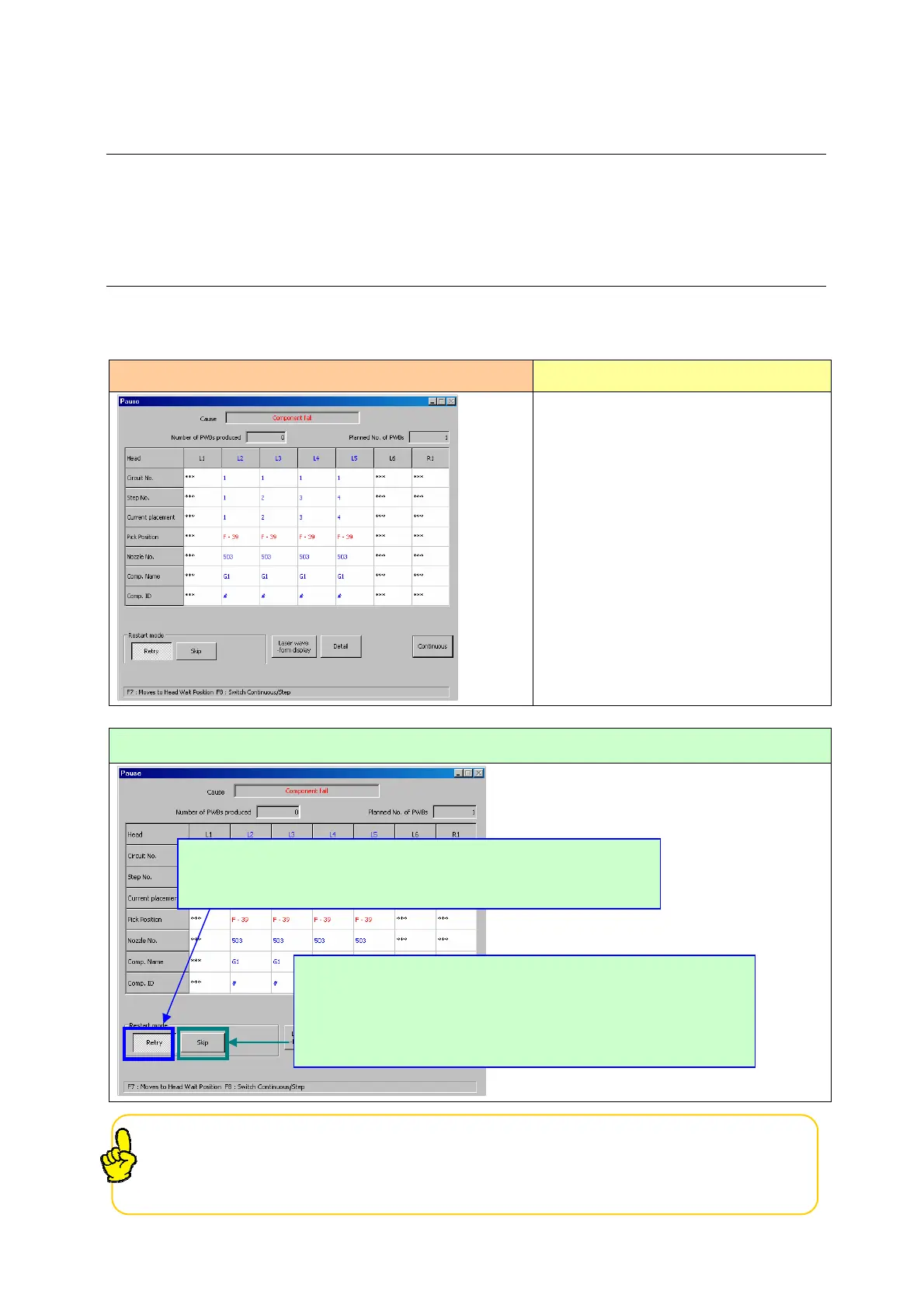

After replenishing the machine with components or removing the cause of

a component run-out error (such as jamming of tape), select the <Retry>

button, and then press the <START> switch.

This button makes the machine skip the placement position at which

components run out to pick up the next component to be placed.

Use this button when you do not have components at hand.

Immediately after the machine finishes placing the components that

can be placed on boards, it pauses again.

Loading...

Loading...