Operation manualⅠ

S-2

Glossary

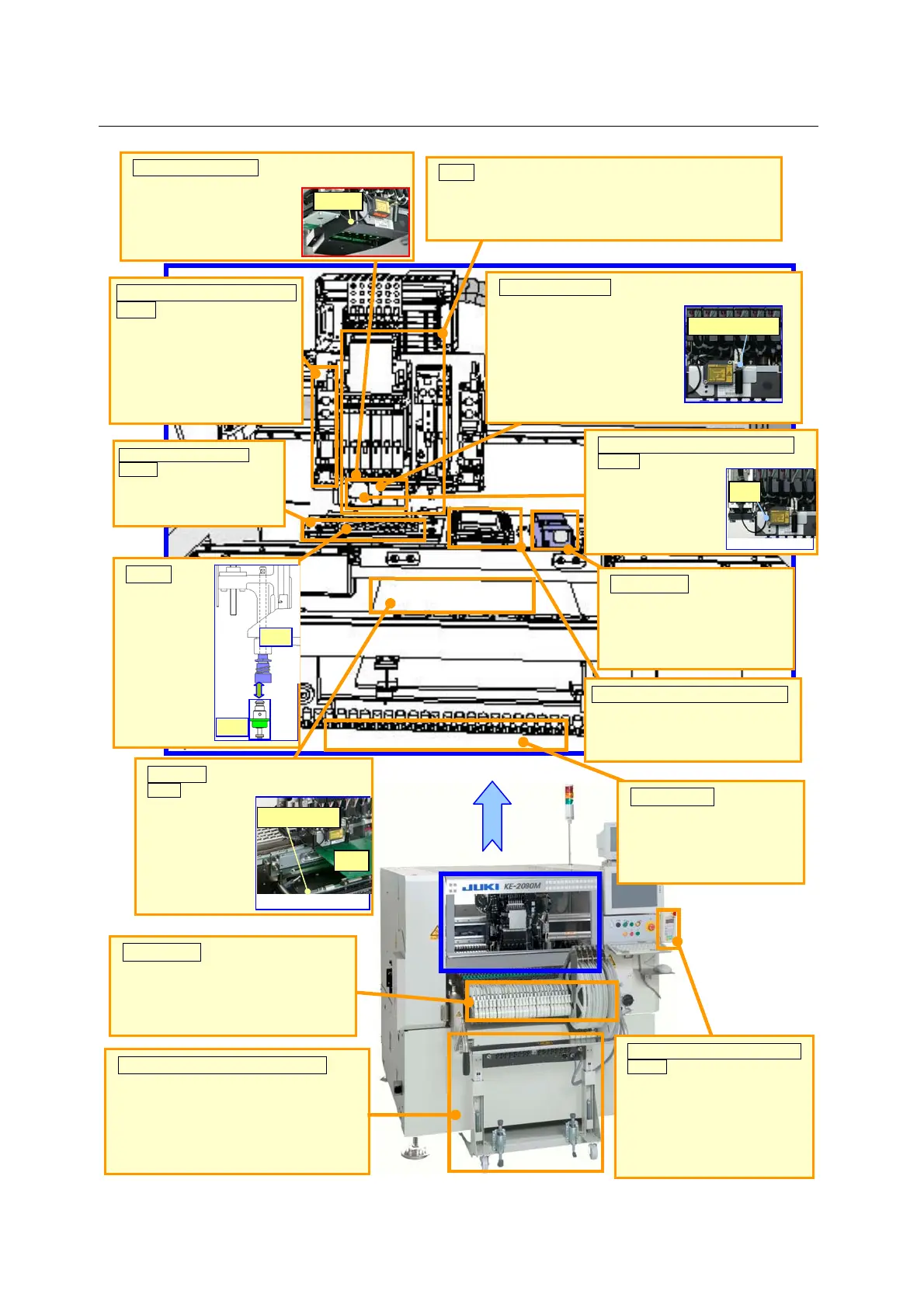

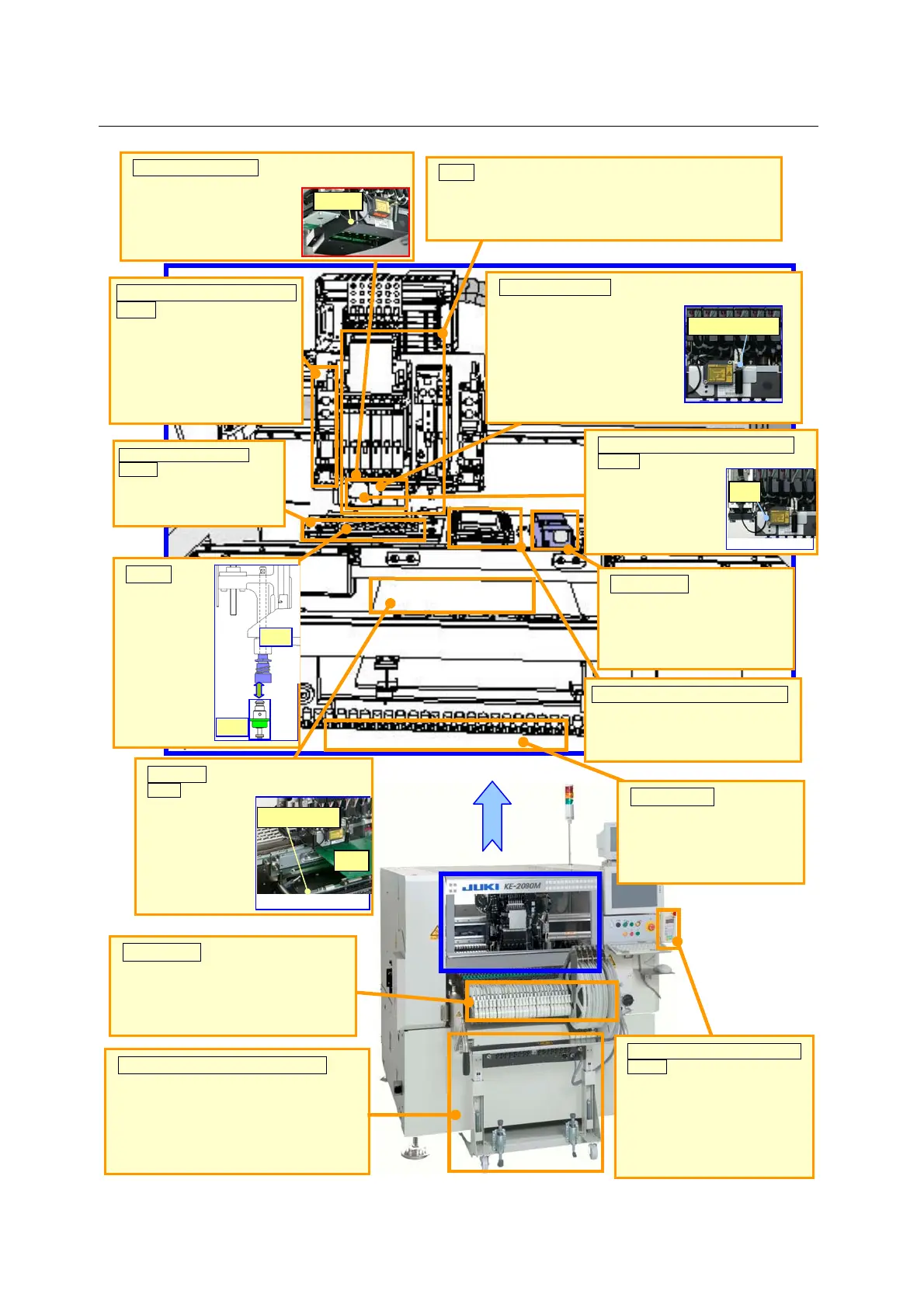

Head

This device picks up, centers and places a component.

The machine is equipped with six “LNC60 heads” and

one “IC head” (for a KE-2080/2080R).

Nozzle

This is a unit

that is to be

attached on

the tip of the

head

(LNC60

head or IC

head) to

pick up a

component.

Head

Nozzle

Bad mark reader

This is a sensor that reads a

symbol (bad mark) marked on

a defective board (circuit) in

case of a multi-circuit board.

The machine does not place a

circuit on which a bad mark is

marked on a board. (Option)

Bad mark reader

LNC60 (Laser unit)

This is a laser unit that finds

the center of a component

(centers a component). (It

can center six components

at the same time.)

LNC60

Support

table

This is a table

that supports a

board. When

a support pin

is used, the

stability

improves.

Support table

Board

Tape feeder

This is a component supplying device

that supplies chip components or othe

type of components to be placed on a

board.

Overall feeder exchange trolley

When a component supplying device

such as a tape feeder is attached on this

trolley and the whole trolley is set on the

machine for changeover of PWB

production, the required time for

changeover can be shortened.

Handheld Operating Device

(HOD)

This is an operation panel for

performing operations such

as adjustment of the

component placement

coordinates on a board

(teaching) with each unit

Coplanarity

This is a sensor that detects

a lead float error of a

component having a lead(s).

(Option)

Feeder bank

This is the base on which a

component supplying

device such as a tape

feeder is to be attached on.

Offset Correction Camera

(OCC)

This is a camera that checks a

mark and/or component

placement coordinates on a

board and/or adjusts the mark

or component placement

position.

Auto Tool Change

(ATC)

This is a unit that stores

nozzles.

Height Measurement System

(HMS)

This is a sensor

that measures the

height of a board

or a component

mainly.

HMS

Vision Centering System (VCS)

This is a camera that finds the

center of a component having a

lead(s) or a ball(s).

Loading...

Loading...