−

24

−

13. Replacing the button feeder components and positioning them

(1) Replacing the button carrier and positioning it

To replace the button carrier, loosen screw

, then remove

the button carrier. Replace the button carrier with one with

a proper center-to-center distance, and t the button carrier

with a proper center-to-center distance to eccentric cam

,

and simultaneously make the top face of the carrier come in

contact with nut

. Now x the carrier by screw

.

(Caution)

The above-statedpositioning procedure shouldbe

carriedoutwiththesewingmachinesettotheorigin.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Buttoncarrier

(2) Replacing the work attachment

Remove the work attachment currently attached on the

sewing machine from the rotary rod. Then attach the work

attachment of another type on the machine. At this time,

be sure to conrm that the work attachment securely ts in

position.

Workattachment

Rotaryrod(nepositioningshaft)

(3) Replacing the feed plate and positioning it

Replacingthepan

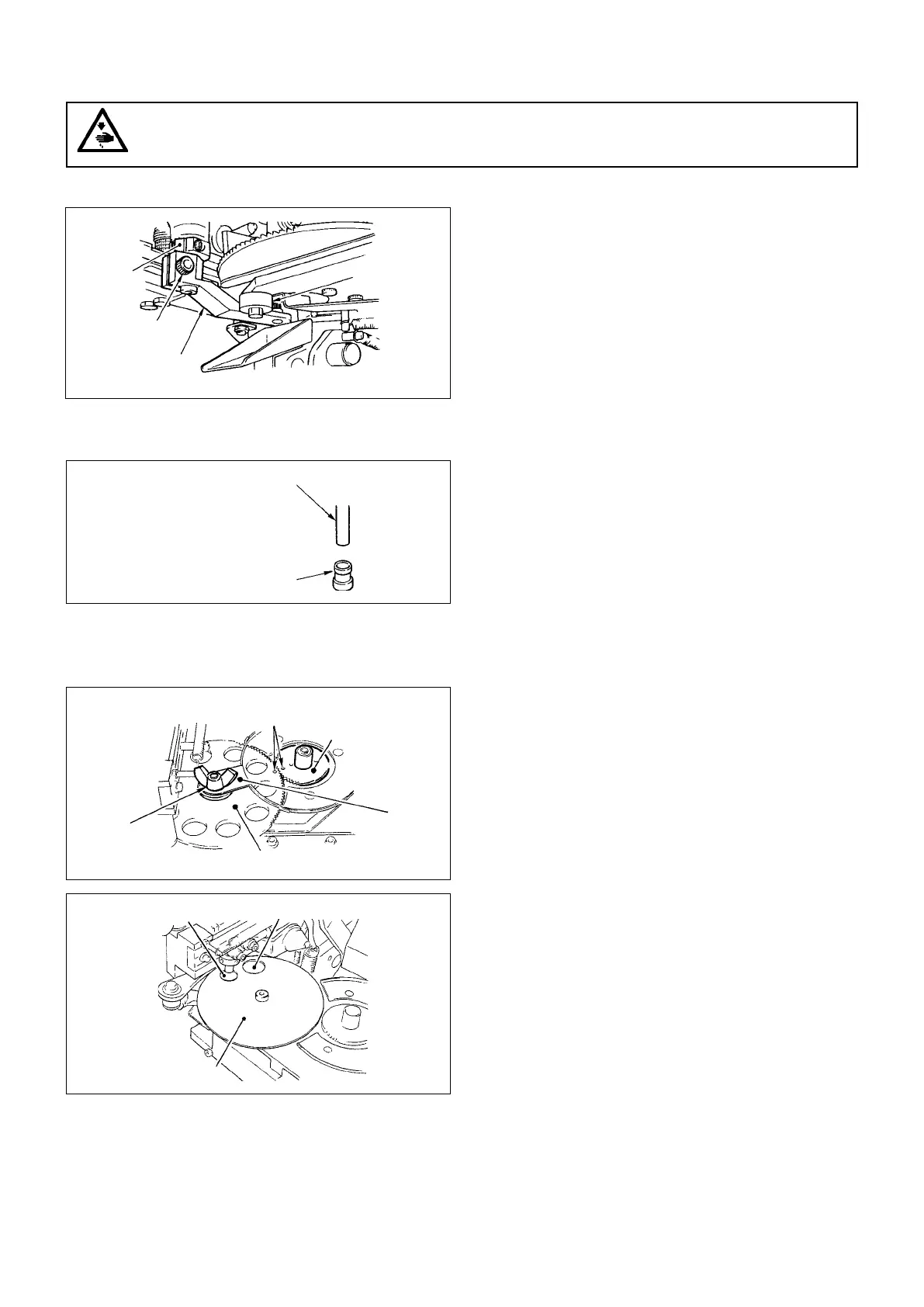

1) Remove buttery nut

, take out cap

, and replace the

feed plate.

Use the feed plate of ø16 mm when sewing buttons of

which diameter is ø10 to ø15 mm. If the outside diameter

of the button is ø16 to ø18 mm, use the feed plate of ø22

mm.

To adjust the position of the feed plate, conrm that the

pinion is in its origin and attach the feed plate at the

position where the matchmark (countersinking) on the

pinion aligns with the matchmark on the feed plate. At this

time, align the hole in the pan with the hole in the feed

plate on the triple pawl.

2) It is necessary to adjust the pan located under the feed

plate to the diameter of the hole in the feed plate. The pan

is provided with two holes, one is ø16 hole and the other

is ø22 mm hole. When using the feed plate of ø16 mm,

attach the pan by turning it over so that its ø16 mm hole

comes this side with respect to the rotational direction

of the feed plate. When using the feed plate of ø22 mm,

attach the pan by turning it over so that its ø22 mm hole

comes this side with respect to the rotational direction of

the feed plate.

3) Adjust the initial position of the triple-pawl taking the value

which is obtained by adding 1 mm to the diameter of the

button hole in the feed plate used as reference.

Make the adjustment using the positioning stopper screw.

Alignwithmatchmarks.

Feedplate

Pan

Pinion

ø16

ø22

Loading...

Loading...