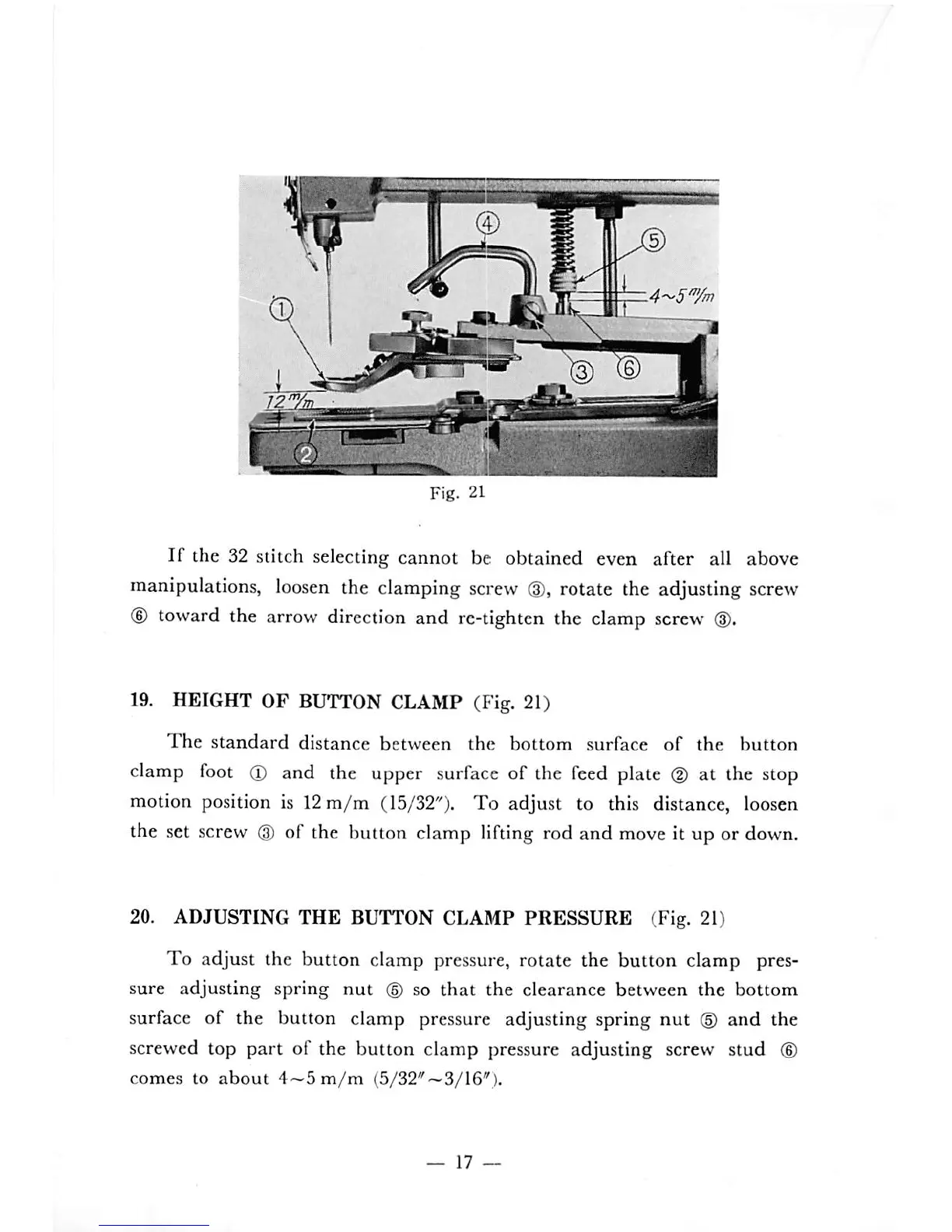

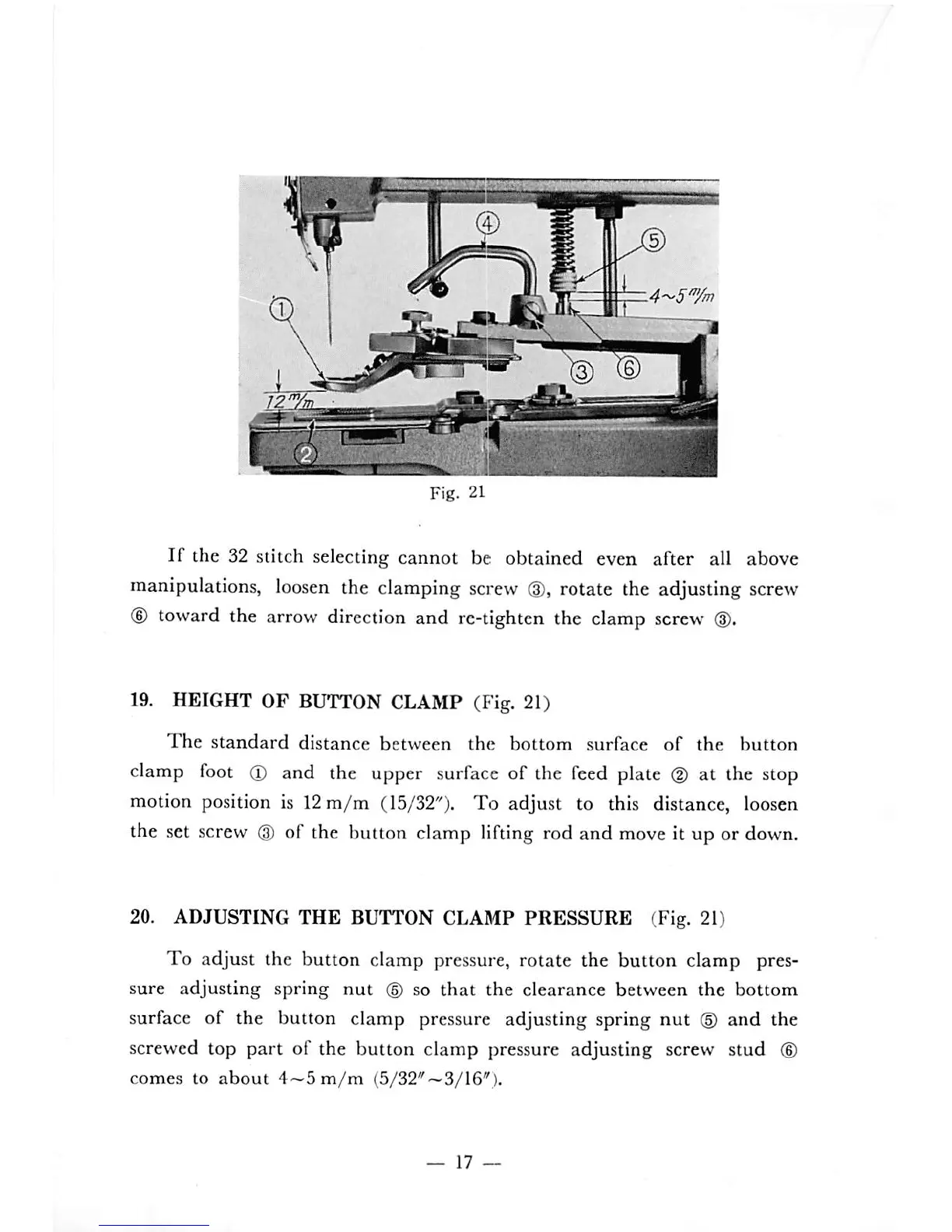

4'^5'ym

® ©

Fig.

21

If

the 32 stitch selecting cannot be obtained even, after all above

manipulations,

loosen

the

clamping

screw

rotate the adjusting

screw

(D

toward

the arrow direction and re-tighten the clamp

screw

(3).

19. HEIGHT OF

BUTTON

CLAMP (Fig. 21)

The

standard

distance

between

the

bottom

surface

of

the

button

clamp

foot

(D

and the upper

surface

of the

feed

plate @ at the stop

motion position is 12

m/m

(15/32"). To adjust to this distance, loosen

the set

screw

(g)

of the button clamp lifting rod and

move

it up or

down.

20. ADJUSTING THE BUTTON CLAMP PRESSURE (Fig.

21)

To adjust the button clamp pressure, rotate the button clamp pres

sure adjusting spring

nut

(D

so

that

the clearance between the

bottom

surface of the button clamp pressure adjusting spring

nut

®

and

the

screwed top

part

of the button clamp pressure adjusting screw stud ®

comes

to

about

4~5m/m

(5/32*'-^3/16").

—

17

—

Loading...

Loading...