Next,

loosen

the

screw

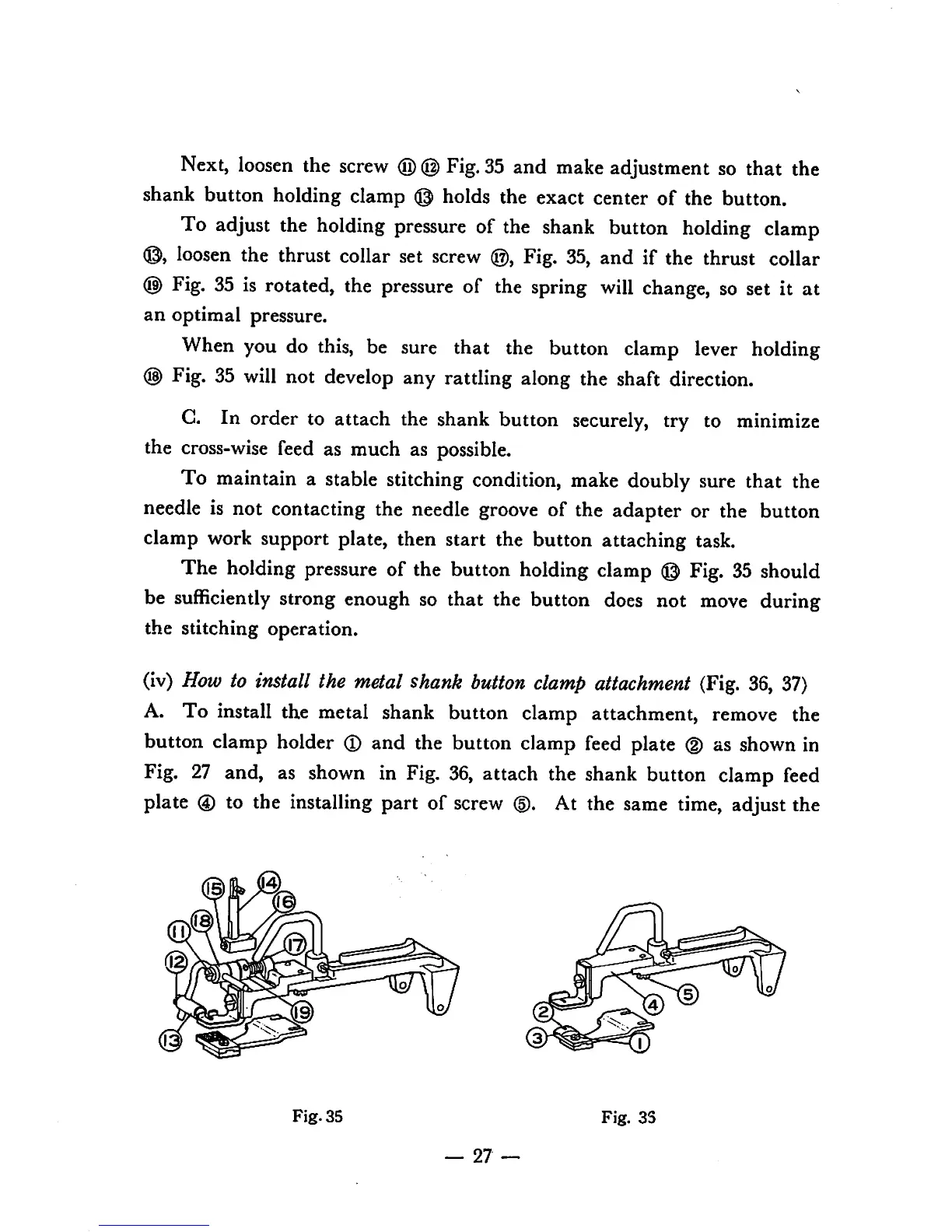

® @Fig.35 and makeadjustment so that the

shank button holding clamp © holds the exact center of the button.

To

adjust

the

holding

pressure

of the

shank

button

holding

clamp

®, loosen the thrust collar set screw ®, Fig. 35, and if the thrust collar

® Fig. 35 is rotated, the

pressure

of the spring will change, so set it at

an optimal pressure.

When you do

this,

be sure that the button clamp lever holding

® Fig. 35 will not develop any rattling along the shaft direction.

G.

In order to attach the shank button

securely,

try to minimize

the

cross-wise

feed as much as possible.

To maintain a stable stitching condition, make doubly sure that the

needle is not contacting the needle

groove

of the adapter or the button

clamp work support plate, then start the button attaching task.

The holding pressure of the button holding clamp ® Fig. 35 should

be sufficiently strong enough so that the button does not move during

the stitching operation.

(iv)

How

to install the metal shank

button

clamp

attachment

(Fig.

36,

37)

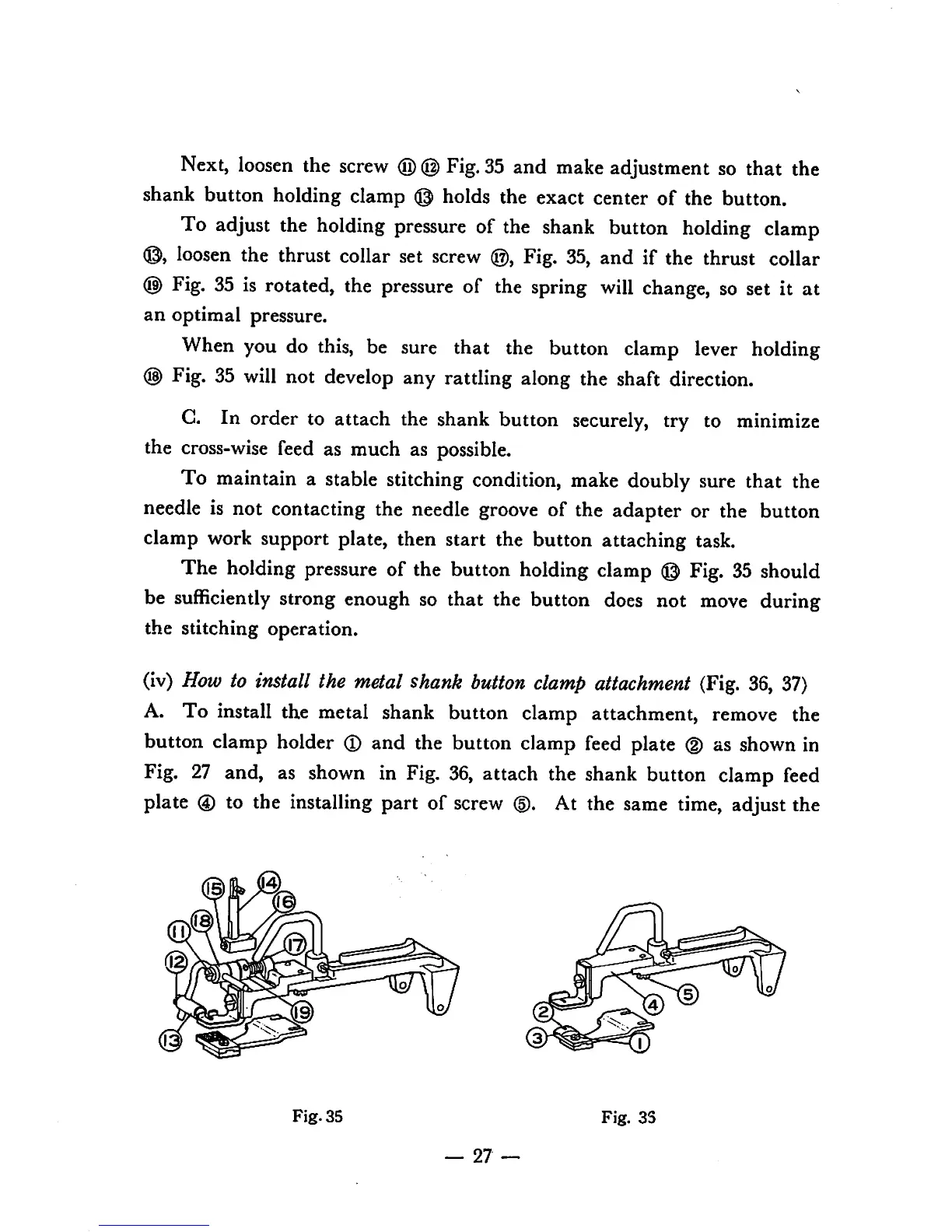

A. To install the metal shank button clamp attachment, remove the

button clamp holder

(T)

and the button clamp

feed

plate

(D

as shown in

Fig.

27

and, as

shown

in

Fig.

36,

attach the shank button clamp

feed

plate @ to the installing part of screw ©. At the same time, adjust the

Fig.

35

Fig.

33

—

27

Loading...

Loading...