Spindle Oil. Remove the right side arm cover, remove the screw d),

Fig. 2, of the needle driving pulley, check the grease level and replenish

it, if required.

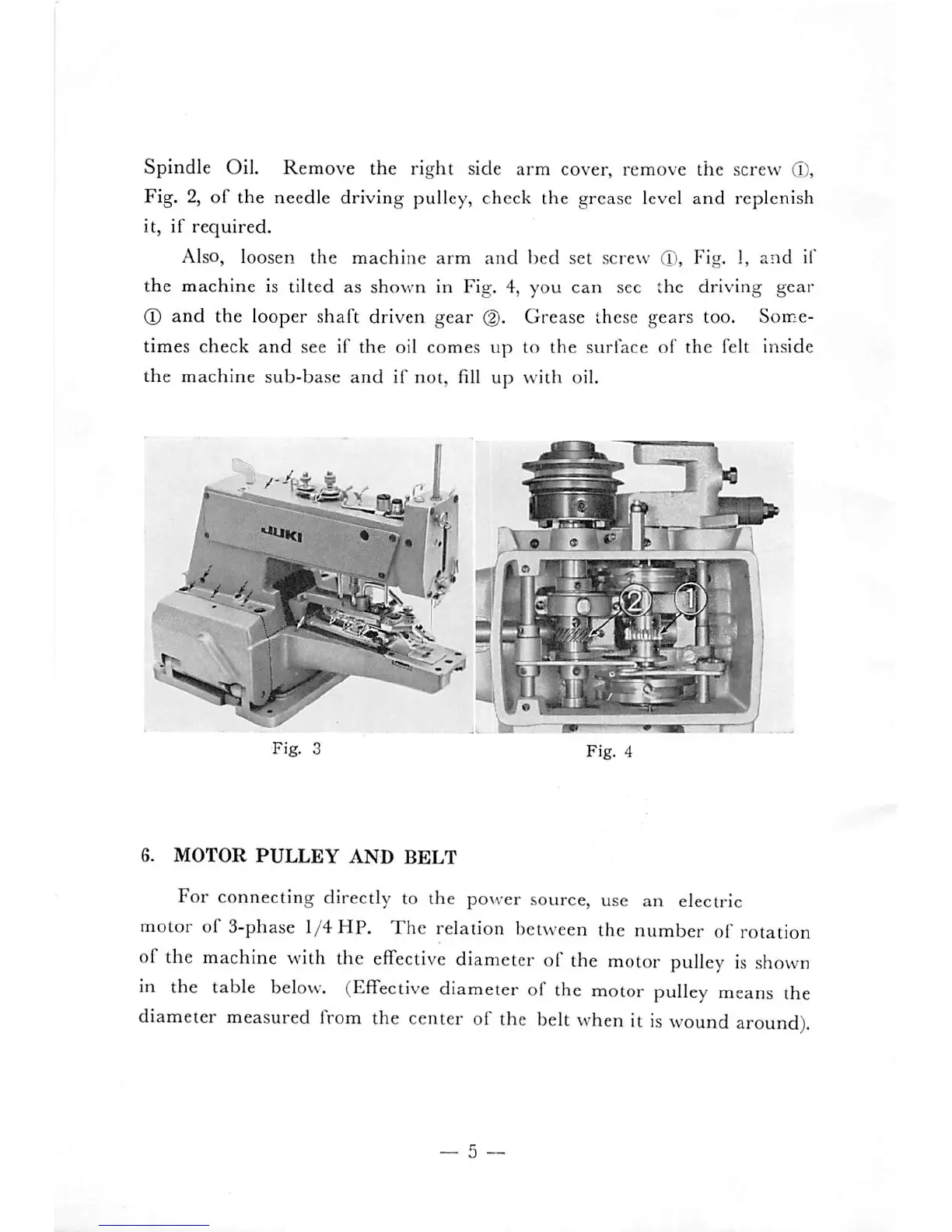

Also, loosen the machine

arm

and

bed set screw ®, Fig. 1,

and

il"

the

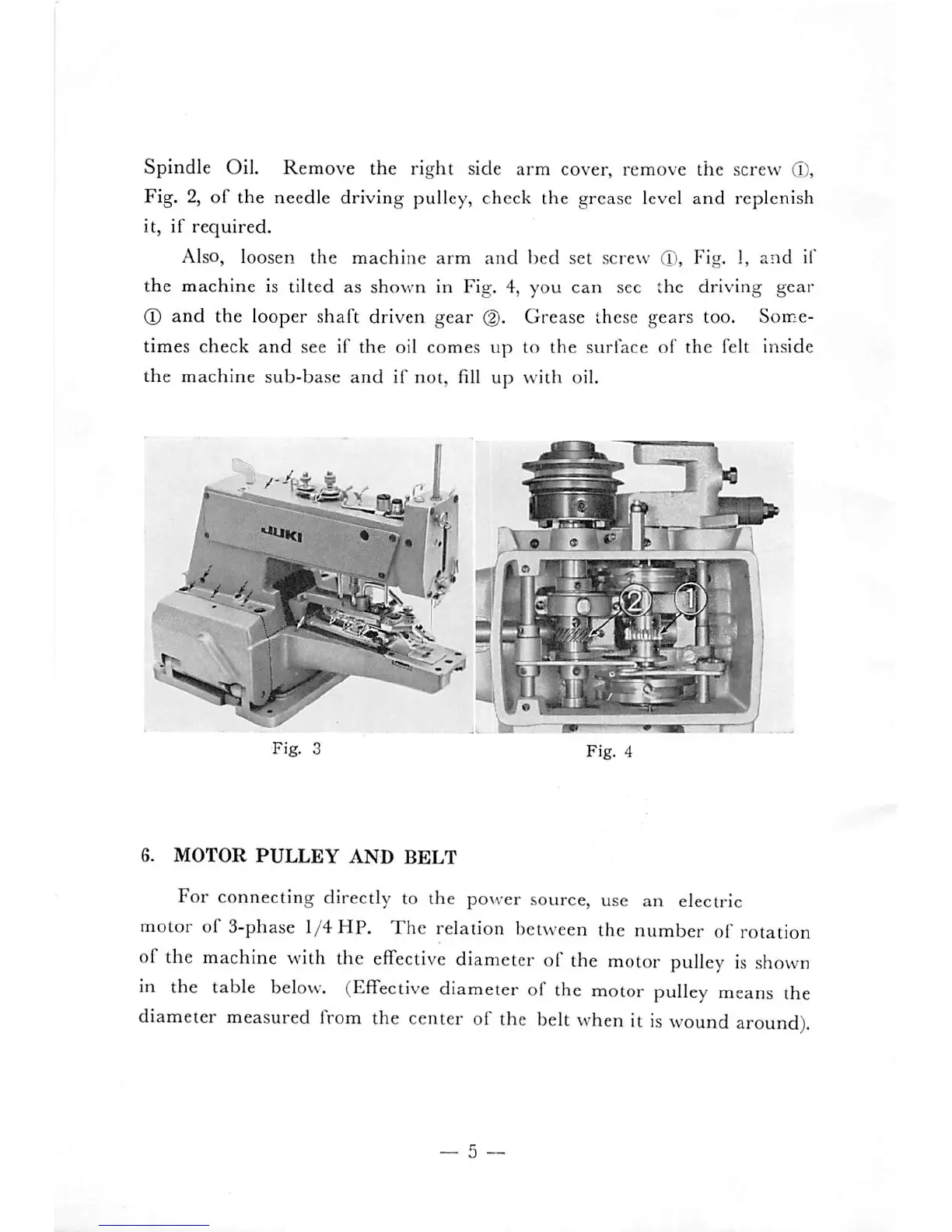

machine is tilted as shown in Fig. 4, you can sec the driving

gear

(T)

and

the looper shaft driven

gear

(2).

Grease these gears too. Some

times check

and

see if the oil comes up to the surface of the felt inside

the machine sub-base and if not, fill up with oil.

=

6.

MOTOR

PULLEY

AND

BELT

For connecting directly to the power source, use an electric

motor of 3-phase 1/4

HP.

The

relation between the

number

of

rotation

of the

machine

with

the

effective

diameter

of the

motor

pulley

is

shown

in the

table

below.

(Effective

diameter

of

the

motor

pulley

means

the

diameter

measured

from

the

center

of

the

belt

when

it

is

wound

around).

— 5 —

Loading...

Loading...