D 5

1001.GB

Adjusting the charging curve

The charging curve can be adjusted by performing the following steps:

Starting the recharging process with integrated battery charger

– Park the truck and render it safe (refer to chapter E).

f

During the recharging operation the tops of the battery cells must be exposed to en-

sure adequate ventilation. Metal objects must not be placed on the battery. Prior to

starting the recharging operation, check all cable connections and plugged connec-

tions for visible damage. The safety instructions provided by the battery supplier and

battery charger supplier must be strictly observed.

Mains supply

Line voltage: 230 V (+10/-15%)

Line frequency: 50 Hz / 60 Hz

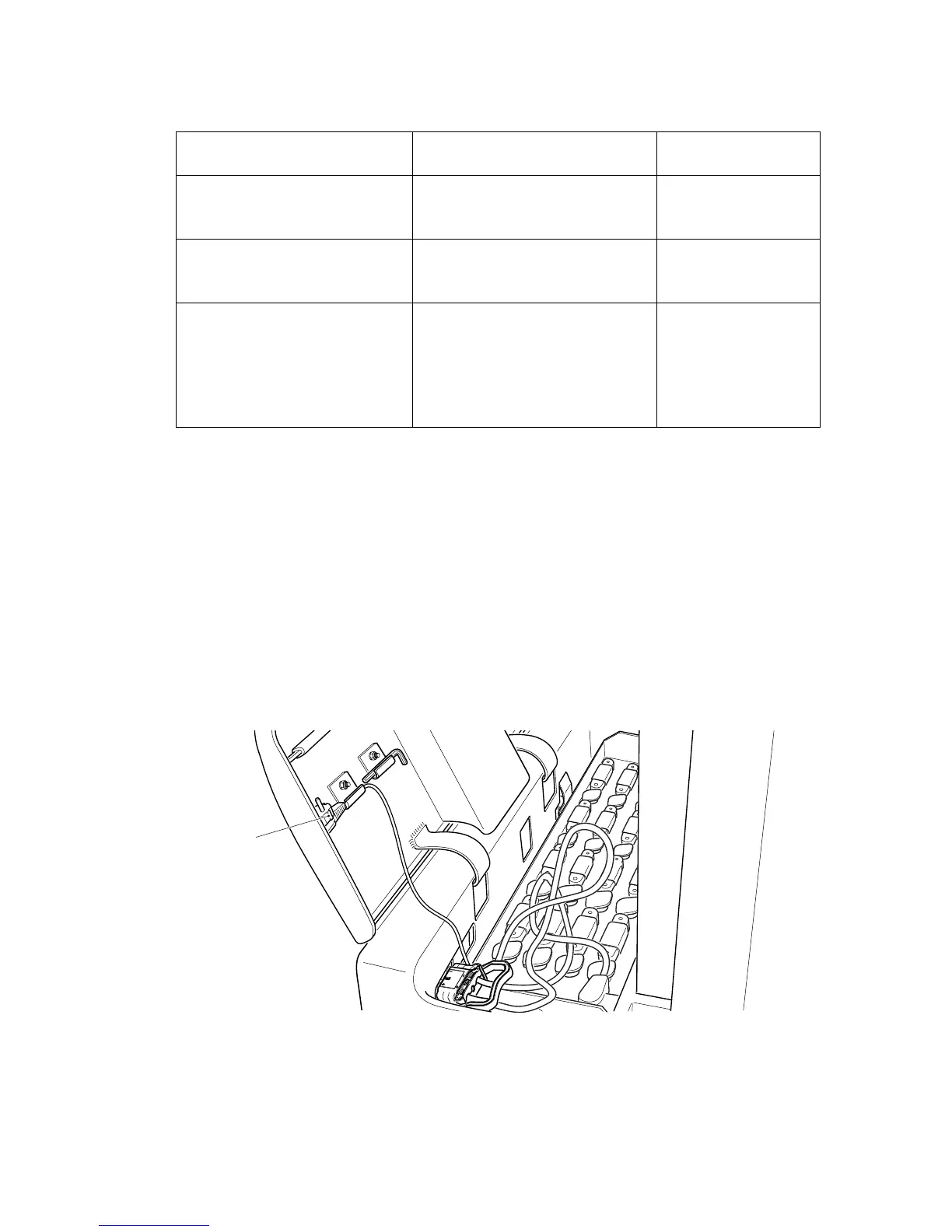

The power plug (8) of the battery charger can be found in the battery compartment.

– Expose the battery (refer to section 3).

– Remove insulation mat from battery, if necessary.

– Pull out master switch (2) (position “ON”).

– Connect power plug (8) with a power socket.

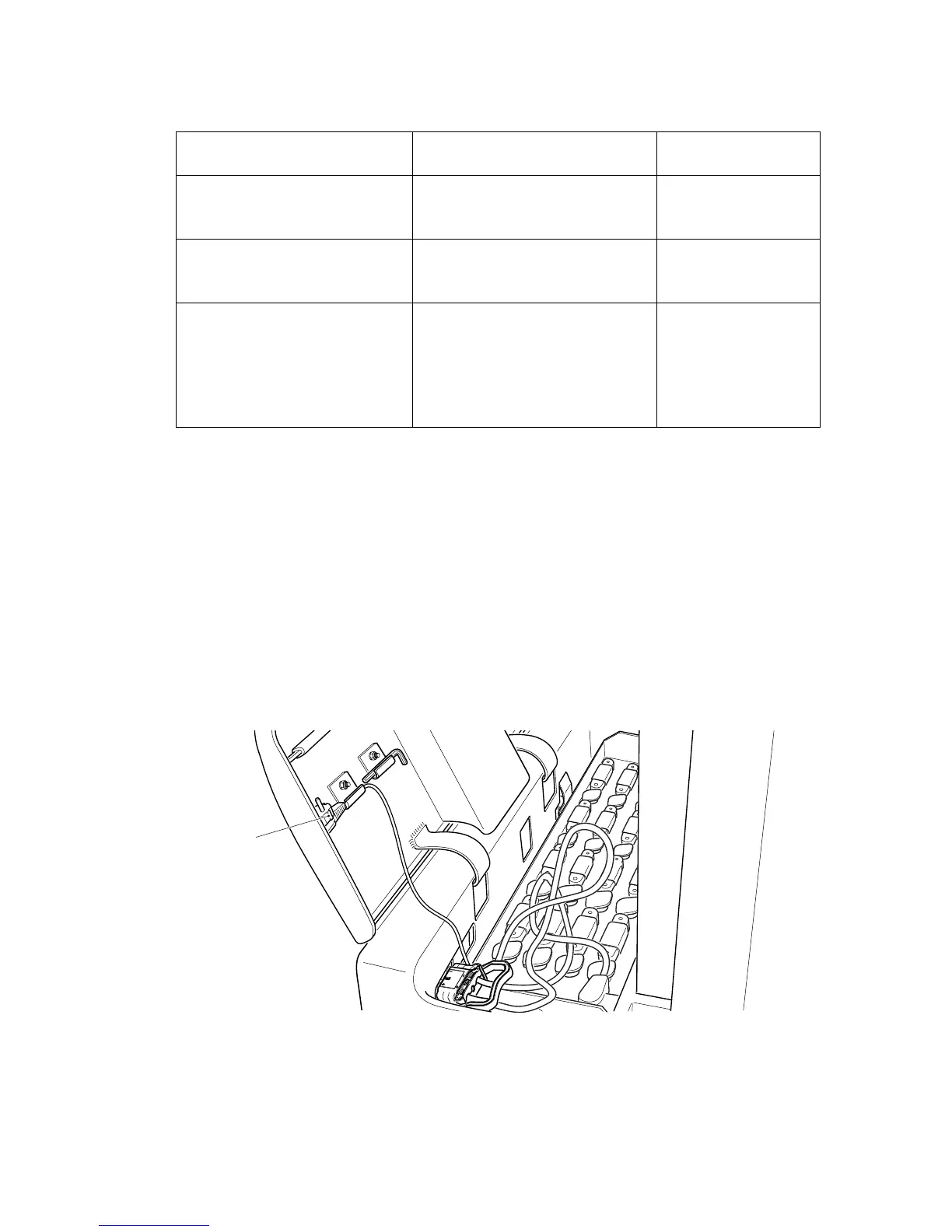

Connect the battery This permits to use the battery

charger as an adjustment aid

Turn the adjustment switch to

the right (i.e. clockwise) until it

touches the limit stop.

The red LED flashes fast no valid

charging curve sel-

ected

Turn the adjustment switch to

the left (i.e. anticlockwise) until

it touches the limit stop.

After 3 seconds the green LED

flashes only once

charging curve 1

selected

Select the desired charging

curve by turning the adjust-

ment switch to the right

The red LED starts to flash in

the intermediate positions.

If a valid charging curve is sel-

ected, the green LED starts to

flash in the relevant switch po-

sition.

8

D 5

1001.GB

Adjusting the charging curve

The charging curve can be adjusted by performing the following steps:

Starting the recharging process with integrated battery charger

– Park the truck and render it safe (refer to chapter E).

f

During the recharging operation the tops of the battery cells must be exposed to en-

sure adequate ventilation. Metal objects must not be placed on the battery. Prior to

starting the recharging operation, check all cable connections and plugged connec-

tions for visible damage. The safety instructions provided by the battery supplier and

battery charger supplier must be strictly observed.

Mains supply

Line voltage: 230 V (+10/-15%)

Line frequency: 50 Hz / 60 Hz

The power plug (8) of the battery charger can be found in the battery compartment.

– Expose the battery (refer to section 3).

– Remove insulation mat from battery, if necessary.

– Pull out master switch (2) (position “ON”).

– Connect power plug (8) with a power socket.

Connect the battery This permits to use the battery

charger as an adjustment aid

Turn the adjustment switch to

the right (i.e. clockwise) until it

touches the limit stop.

The red LED flashes fast no valid

charging curve sel-

ected

Turn the adjustment switch to

the left (i.e. anticlockwise) until

it touches the limit stop.

After 3 seconds the green LED

flashes only once

charging curve 1

selected

Select the desired charging

curve by turning the adjust-

ment switch to the right

The red LED starts to flash in

the intermediate positions.

If a valid charging curve is sel-

ected, the green LED starts to

flash in the relevant switch po-

sition.

8

Loading...

Loading...