2-2

2.2 DISASSEMBLY/ASSEMBLY OF MECHANISM PARTS

This procedure starts with the condition that the cabinet parts and deck parts. Also, all the following procedures for adjust-

ment and parts replacement should be performed in STOP mode. When reassembling, perform the step(s) in the reverse

order.

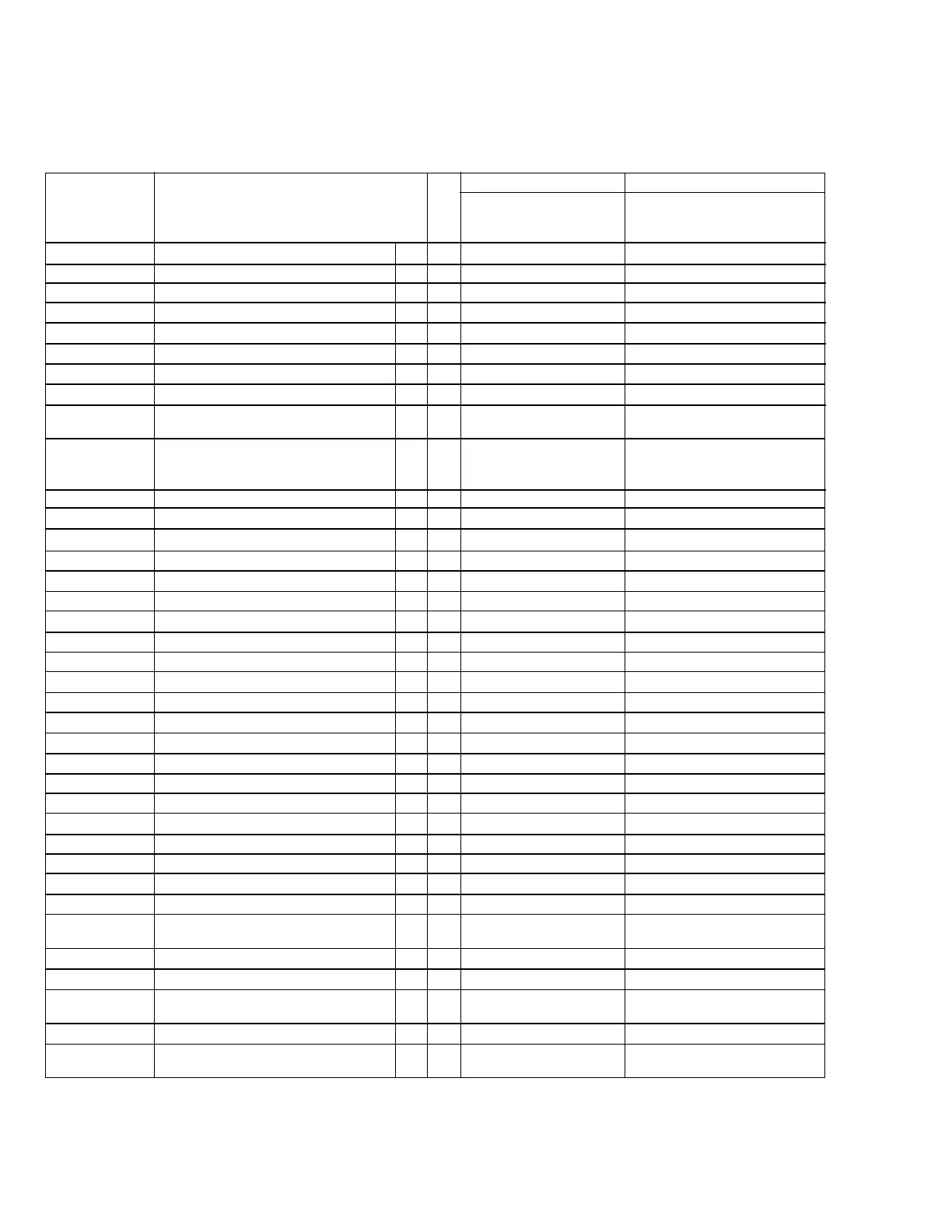

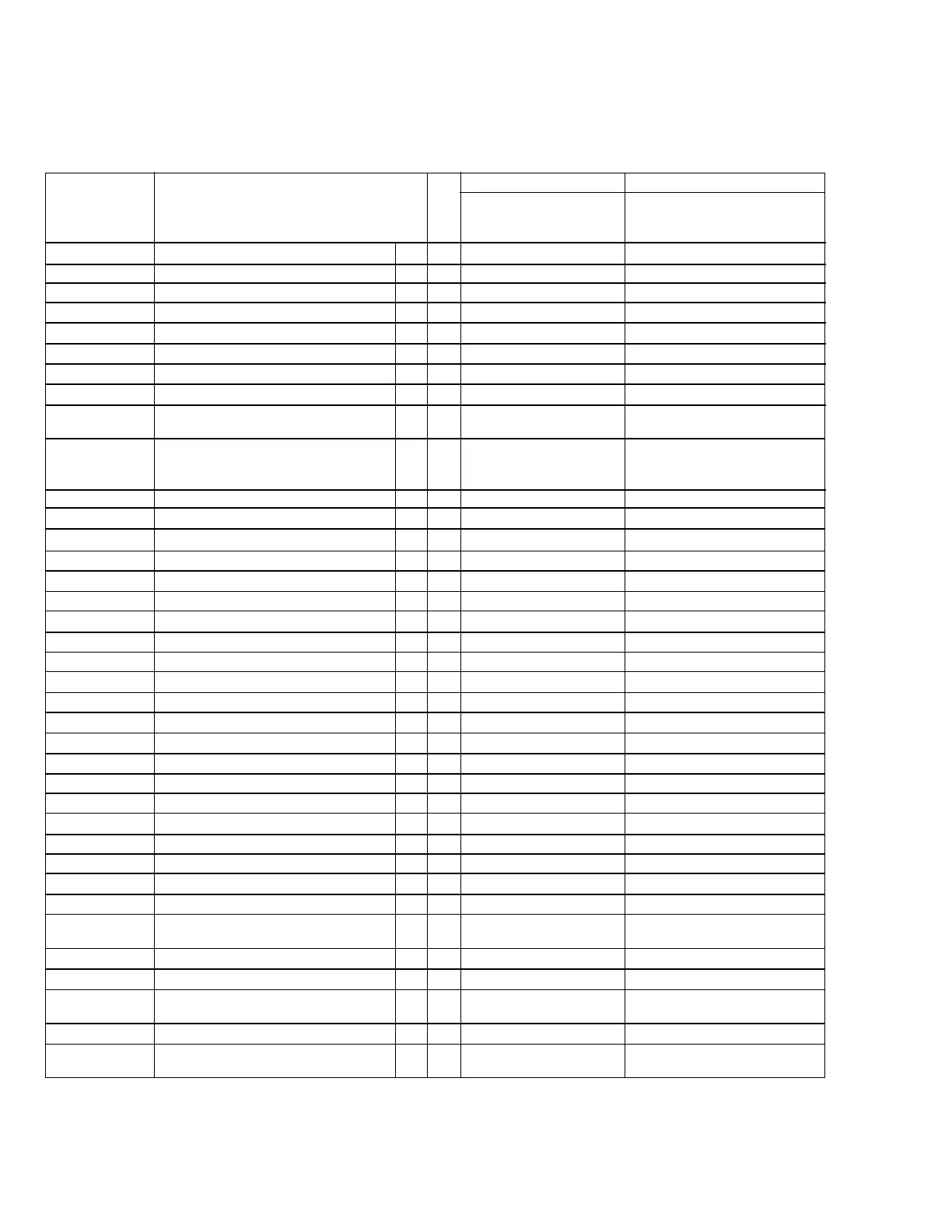

Table 2-2-1

1

ROLLER BASE ASSEMBLY T M1 (S1) –

2

TENSION ARM ASSEMBLY T M1 (P1), (W1a) –

3

4

REEL DISC (SUP) T M1 (W1a), (W1b) –

SLANT ARM ASSEMBLY T M1 (W1a) –

5

CANCEL LEVER ASSEMBLY T M2 (W2) –

6

EJECT LEVER ASSEMBLY T M2 (W2) –

7

CASSETTE GUIDE (L) ASSEMBLY T M2 (S2) –

8

SUPPLY CLUTCH ASSEMBLY T M2 (W2) –

9

WHEEL GEAR T M2 (W2) See, Adjustment procedure for

Section 2.3

0

ROTARY ENCODER B M3 4(S3a)

!

TIMING BELT B M3 – –

@

CENTER PULLEY UNIT T/B M3 2(S3a) –

#

CASSETTE GUIDE (R) ASSEMBLY T M3 (S3b), (P3) (Only use S-VHS model)

$

TU GEAR T M3 (W3a) –

%

BRAKE SUB GEAR T M3 (W3a) –

^

P.R ARM ASSEMBLY T M3 (W3b) –

&

TU GUIDE ARM ASSEMBLY T M3 (W3a) –

*

LINK ARM ASSEMBLY T M4 (W4) –

(

LED GUIDE T M4 (S4a) –

)

A/C HEAD UNIT T M4 2(S4b) –

q

SLANT POLE BASE ASSEMBLY T M5 (S5a) –

w

CAP MOTOR ASSEMBLY T M5 3(S5a) –

e

MOTOR BASE T M5 2(S5b), (S5c) –

r

BRUSH B M6 (S6a) –

t

DRUM FINAL T/B M6

2(S6b), 2(S6c)

*

CATCHER

–

y

GUIDE RAIL T M6 8(S6d) –

u

POLE BASE (SUP) T M6 – –

i

POLE BASE (TU) T M6 – –

o

COVER PLATE T M7 – –

p

DRIVE LEVER ASSEMBLY T M7 – –

Q

MOTOR BRACKET ASSEMBLY T M7 3(S7) –

W

CONTROL CAM T M8 (W8a) See, Adjustment procedure for

Section 2.3

E

LINK LEVER T M8 – –

R

MIDDLE GEAR T M8 – –

T

LOADING GEAR(T) ASSEMBLY T M8 (W8b) See, Adjustment procedure for

Section 2.3

Y

LOADING GEAR(S) ASSEMBLY T M8 (W8b) –

U

LOADING RING ASSEMBLY T M8 4(S8) See, Adjustment procedure for

Section 2.3

STEP/LOC.

No.

PART

REMOVAL INSTALLATION

*UNHOOK/UNLOCK ADJUSTMENT

/RELEASE/UNPLUG CONDITION

/UNSOLDER NOTE

Fig.

No.

The function of this part varies according

to the assembly (VHS/S-VHS) which this

part is rporated in.

Loading...

Loading...