SECTION 5

MAINTENANCE

5.1 INTRODUCTION

This section contains information necessary to maintain the

Model 220. Calibration adjustment, troubleshooting, fuse

replacement, line voltage selection, fan filter cleaning and all

information pertinent to maintenance is provided.

5.2 CALIBRATION

Calibration should be performed yearly (every 12 months.1 or

whenever performance verification (see Section 3) indicates

that the Model 220 is out of specification. If any step in the

calibration procedure cannot be performed properly, refer to

paragraph 5.4 for troubleshooting information or contact

your Keithley representative or the factory.

WARNING

All service information is intended for

qualified electronic maintenance person-

nel only.

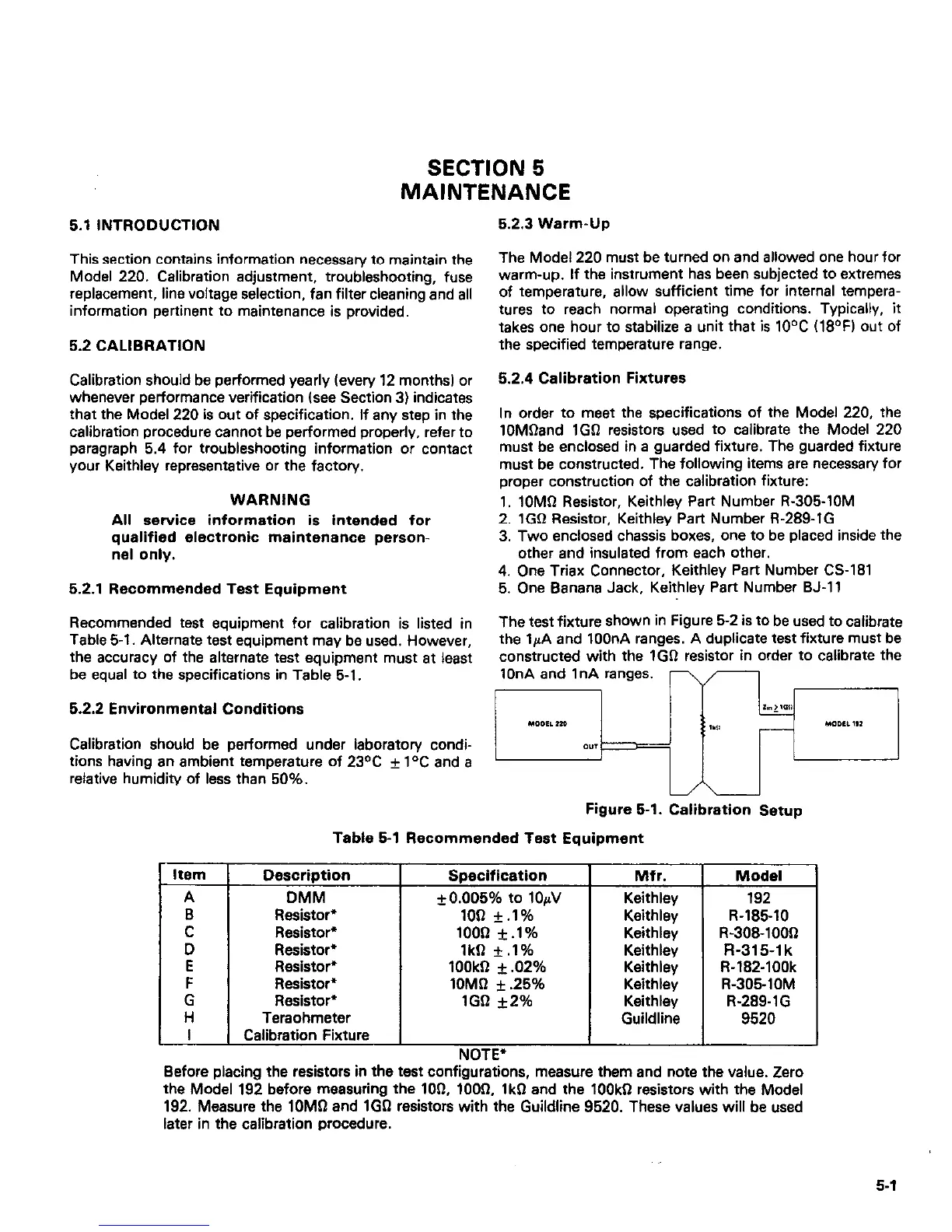

5.2.1 Recommended Test Equipment

Recommended test equipment for calibration is listed in

Table 5-1. Alternate test equipment may be used. However,

the accuracy of the alternate test equipment must at least

be equal to the specifications in Table 5-I.

5.2.2 Environmental Conditions

Calibration should be performed under laboratory condi-

tions having an ambient temperature of 23°C f I°C and a

relative humidity of less than 50%.

5.2.3 Warm-Up

The Model 220 must be turned on and allowed one hour for

warm-up. If the instrument has been subjected to extremes

of temperature, allow sufficient time for internal tempera-

tures to reach normal operating conditions. Typically, it

takes one hour to stabilize a unit that is IO°C 118°F) out of

the specified temperature range.

5.2.4 Calibration Fixtures

In order to meet the specifications of the Model 220, the

IOMDand 1GIl resistors used to calibrate the Model 220

must be enclosed in a guarded fixture. The guarded fixture

must be constructed. The following items are necessary for

proper construction of the calibration fixture:

I. 1OMR Resistor, Keithley Part Number R-305-10M

2. IGQ Resistor, Keithley Part Number R-289-1G

3. Two enclosed chassis boxes, one to be placed inside the

other and insulated from each other.

4. One Triax Connector, Keithley Part Number CS-181

5. One Banana Jack, Keithley Part Number BJ-II

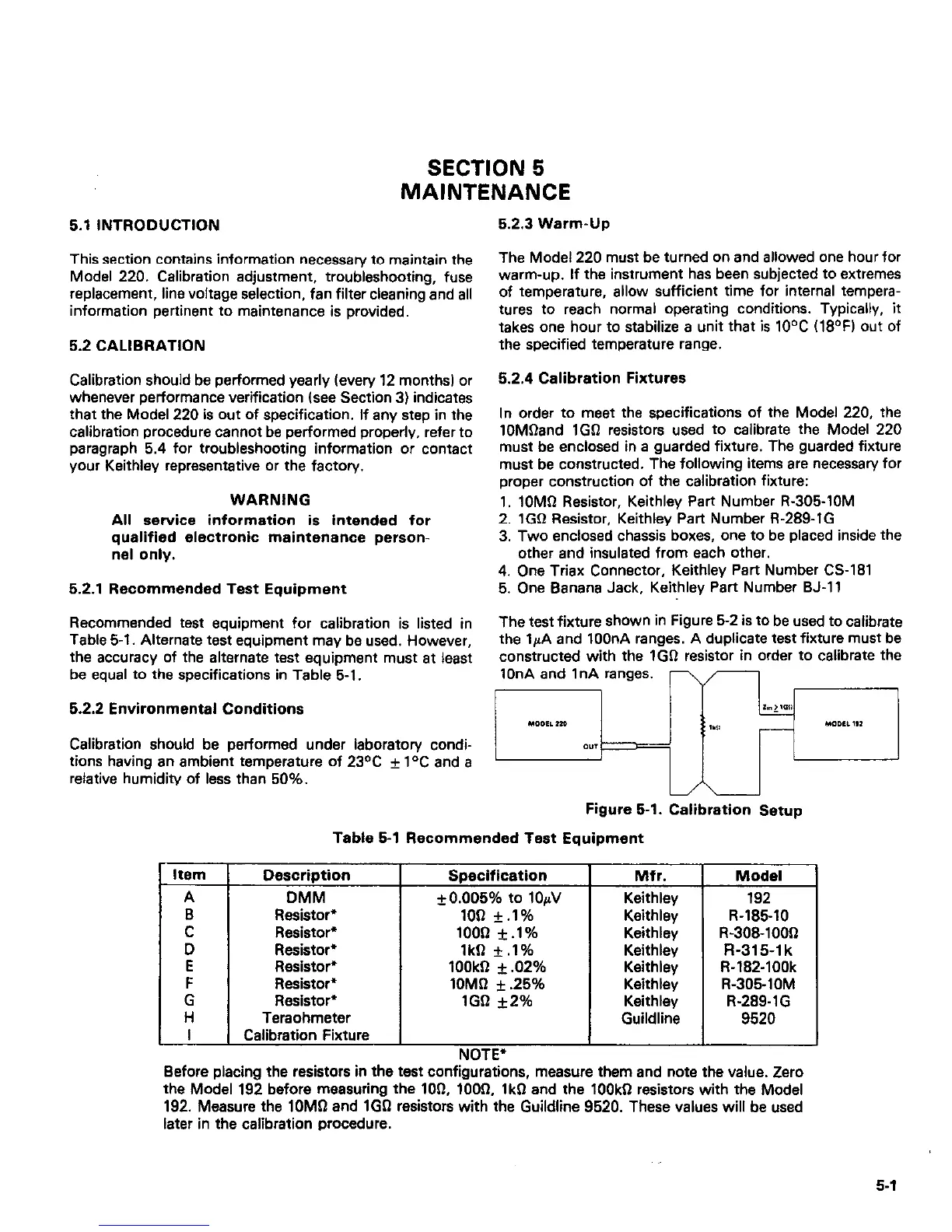

The test fixture shown in Figure 5-2 is to be used to calibrate

the 1fiA and lOOnA ranges. A duplicate test fixture must be

constructed with the 1GTi resistor in order to calibrate the

1OnA and InA ranges.

Figure 5-l. Calibration Setup

Table 5-l Recommended Test Equipment

Item

A

:

D

E

F

:

I

Description

DMM

Resistor”

Resistor*

Resistor*

Resistor*

Resistor*

Resistor*

Teraohmeter

Calibration Fixture

Specification

f0.00596 to lo&

100 k.l%

loon f .l%

IkD f .l%

1OOkfl + .02%

IOMD f .25%

1GD ~2%

NOTE*

.

Before placing the resistors in the test configurations, measure them and note the value. Zero

the Model 192 before measuring the 100, lOOR, 1kD and the 1OOkR resistors with the Model

192. Measure the 1OMD and 1GD resistors with the Guildline 9520. These values will be used

later in the calibration procedure.

Mfr.

Keithley

Keithley

Keithlev

Keithley

Keithley

Keithlev

Keithlev

Guildline

Model

192

R-185-10

R-308-1003

R-315-1 k

R-182s100k

R-305~10M

R-289-I G

9520

5-1

Loading...

Loading...