4. When cleaning the element, refer

to the instructions that follow.

5. If the element is stained with car

-

bon , dust or oil, replace the lter.

6. Change the element every 6 months

or every 100 hours.

To clean the element, use only clean

dry compressed air on the inside

of the element. Air pressure at the

nozzle must not exceed 29 psi (2 kgf/

cm²). Maintain reasonable distance

between the nozzle and the lter.

The air cleaner will only fulll

its function if it is correctly

and regularly maintained. A

poorly maintained air cleaner

will mean loss of power, ex-

cessive fuel consumption and

a reduction in engine life.

IMPORTANT

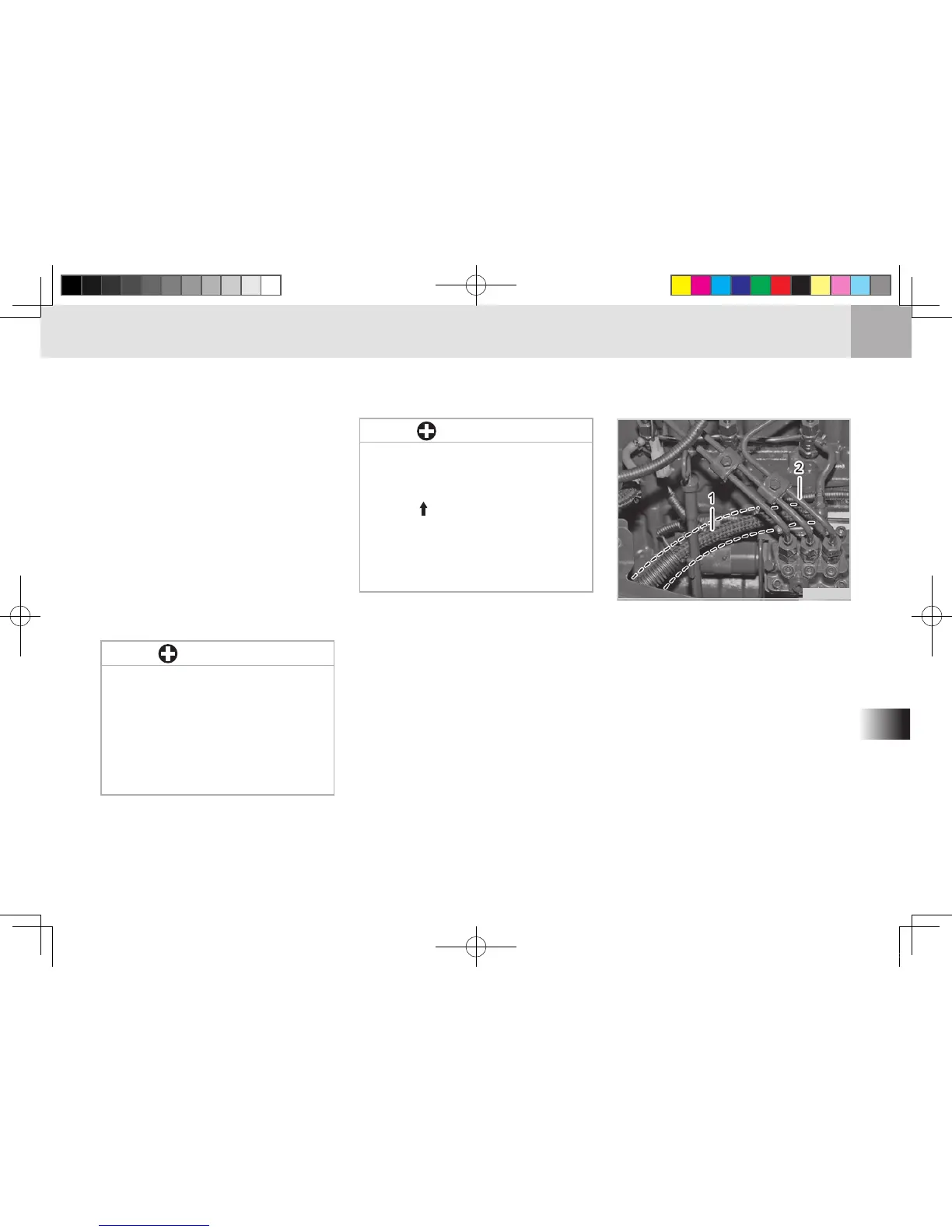

(1) Fuel Pipe (2) Tightening Band

CHECKING FUEL LINES (U)

Although checking the fuel pipe con-

nection is recommended every 100

service hours, it should be done ev-

ery 6 months if operation does not

exceed 100 hours in 6 months.

1. If the hose clamps are loose, apply

a slight coat of lubricant onto the

threads and securely tighten it.

2. The fuel pipe is made of rubber and

ages regardless of period of ser-

vice. Change the fuel pipe together

with the hose clamps every two

years and securely tighten.

EVACUATOR VALVE

Open the evacuator valve once a

week under ordinary conditions or

daily when used in dusty conditions

to get rid of large particles of dust

and dirt.

Do not run the engine with l-

ter element removed.

Be sure to ret the cap with the

arrow (on the rear of cover)

upright. If the cap is improperly

tted, evacuator valve will not

function and dust will adhere

to the element.

IMPORTANT

M46O725A

Loading...

Loading...