6-6 Installation TP-5592 7/96

Locatethefuelreturnlineasfaraspracticalfromthefuel

pickup to allow tank fuel to cool return fuel before

delivery back to the fuel injectors. Incoming fuel cools

the injectors and achieves maximum engine efficiency

by supplying cool fuel to the engine. Fuel tank capacity

and amount of fuel will affect cooling capability.

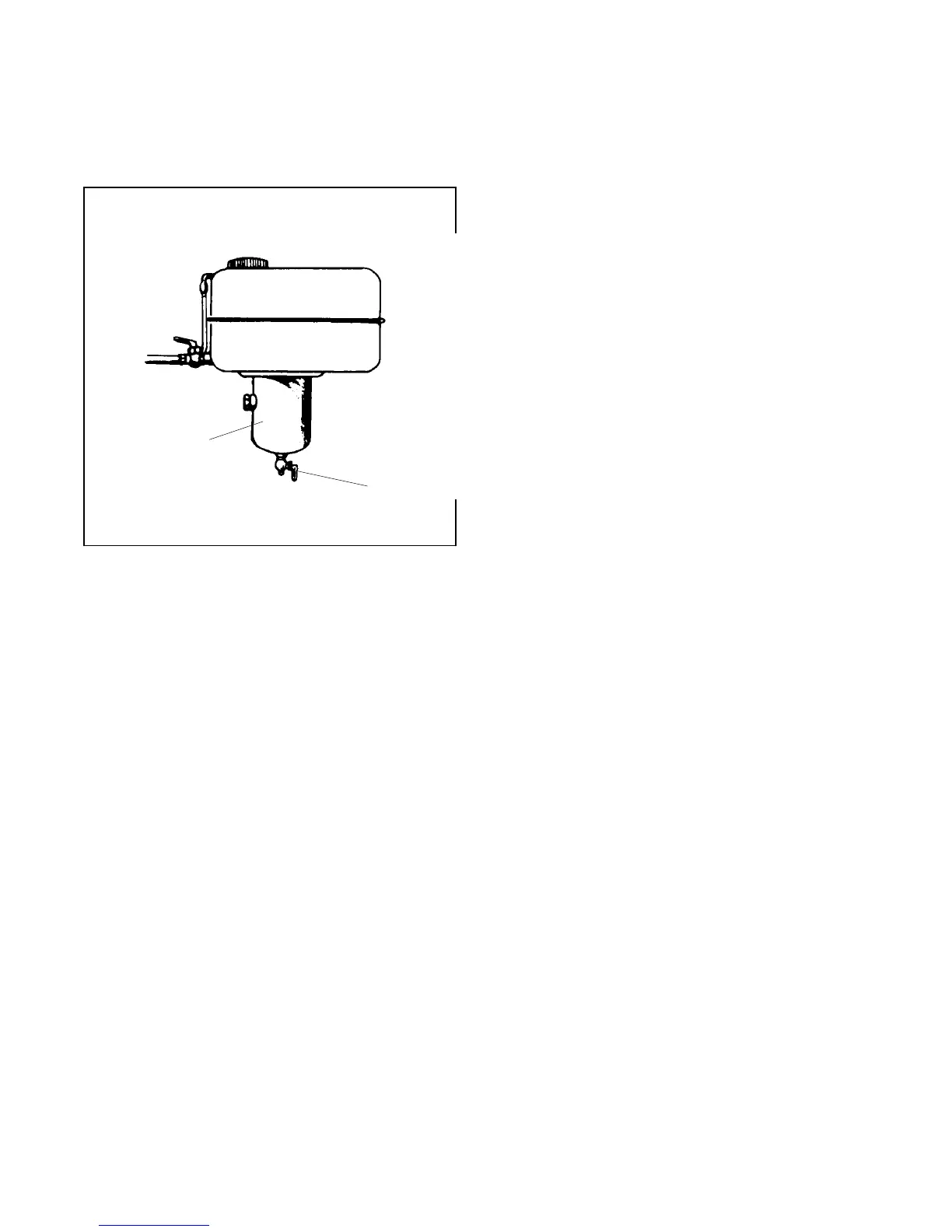

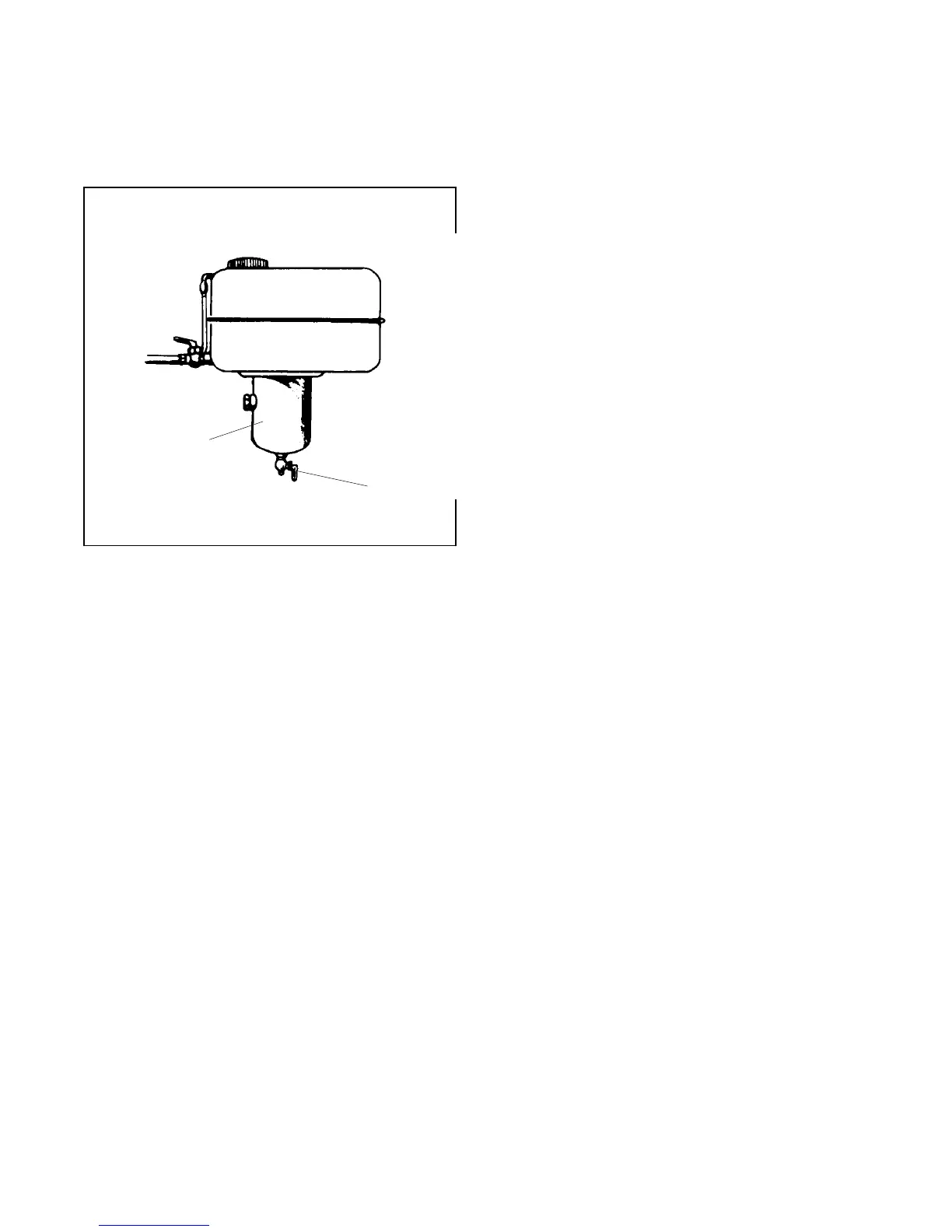

1-788

1

2

1. Precipitation tank

2. Drain petcock

Figure 6-5. Precipitation Tank (typical)

Under no circumstances should the propulsion engine

and generator set share mutual pickup or return lines

(tee arrangement) which would allow the larger engine

tostarve fuel fromthe smaller engine. It is alsopossible

that the operation of either engine could completely

drain the fuel line of the other engine and make starting

difficult.

Anti-Siphon Provisions

USCG Regulations do not require anti-siphoning

devices with diesel-powered applications. Therefore,

Kohler Co. does not recommend using anti-siphoning

devices.

Fuel Lines And Filters

Usemetalliclinesfromthetanktoaflexiblehosesection

to connect a metallic line to the engine fuel pump inlet

connection point. Use metallic lines from the tank to a

flexible hose section connecting metallic line to the fuel

return line connection point. The flexible hose section

allows vibrational motion of the generator set during

operation. Use 3/8 in. ID size customer-supplied fuel

lines to connect to the fuel pump and fuel return. Fuel

lines and fuel line supports must comply with USCG

Regulations 33CFR183.

See Figure 6-6 for fuel feed pump inlet connection and

fuel return line connection.

Anyin-linefuelfiltersorstrainersmustconformtoUSCG

Regulations.

Fuel Pump Lift Capabilities And

Fuel Consumption

Locate the fuel pump lift capabilities, fuel line size/type,

and generator set fuel consumption rates in Section

1—Specifications.

Loading...

Loading...