TP-6805 8/1598 Section 6 Component Testing and Adjustment

6.4 Main Field (Rotor)

The two-pole rotor creates the magnetic field needed to

produce alternating current in the stator windings.

Before testing, inspect the rotor for visible damage to

pole shoes, insulation, exposed coil windings, and slip

ring surfaces. Rotate the bearing to check for wear, heat

discoloration, or noise.

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or equipment connected to the set, disable the

generator set as follows: (1) Press the generator set off/reset

button to shut down the generator set. (2) Disconnect the

power to the battery charger, if equipped. (3) Remove the

battery cables, negative (--) lead first. Reconnect the negative

(--) lead last when reconnecting the battery. Follow these

precautions to prevent the starting of the generator set by the

remote start/stop switch.

High voltage test. Hazardous voltage can cause severe

injury or death. Follow the instructions of the test equipment

manufacturer when performing high-voltage tests on the rotor

or stator. An improper test procedure can damage equipment

or lead to generator set failure.

Grounding electrical equipment. Hazardous voltage can

cause severe injury or death. Electrocution is possible

whenever electricity is present. Ensure you comply with all

applicable codes and standards. Electrically ground the

generator set, transfer switch, and related equipment and

electrical circuits. Turn off the main circuit breakers of all

power sources before servicing the equipment. Never contact

electrical leads or appliances when standing in water or on wet

ground because these conditions increase the risk of

electrocution.

Rotor Test Procedure

1. Press the OFF button on the controller to turn off

the generator set.

2. Disconnect utility power to the generator set.

3. Disconnect the generator set engine starting

battery, negative (--) lead first.

4. Check the rotor for continuity and resistance.

a. Raise and secure the b rushes away from the

slip rings by removing the two brush holder

mounting screws and moving the brush

assembly out of the way.

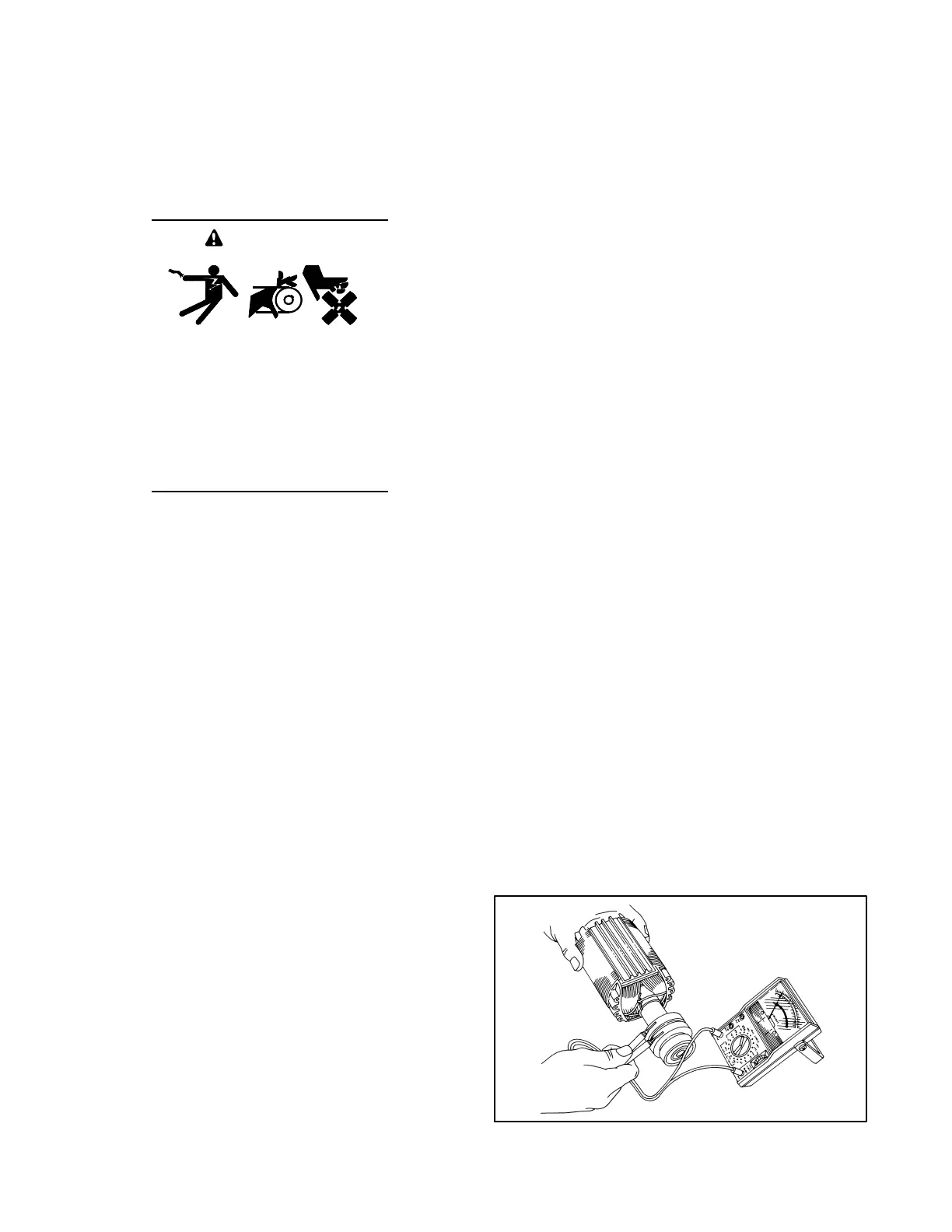

b. Measure the rotor resistance (ohms) between

the two slip rings; see Figure 6-9. See Section

1.6 for rotor resistance readings.

Note: Because ohmmeter accuracy varies,

resistance readings are approximate. Take

readings at room temperature.

c. If the resistance readings are low, perform a

megohmmeter test on rotor as described in the

next step.

5. Perform a megohmmeter test to determine

whether the rotor is shorted to ground.

a. Raise and secure the b rushes away from the

slip rings by removing the two brush holder

mounting screws and moving the brush

assembly out of the way.

b. Using a megohmmeter, apply 500 volts DC to

one rotor slip ring and the rotor poles or shaft.

Follow the instructions of the megohmmeter

manufacturer when performing this test.

Note: A reading of approximately 500 kOhms

(1/2 megohm) or higher indicates a

good rotor.

c. Repair or replace the rotor if the reading is less

than approximately 500 kOhms. A reading of

less than 500 kOhms indicates deterioration of

the winding insulation and possible current flow

to ground.

d. Following the test, remove the retainer wire

from the brush holder and check the brush

positions on the slip rings. See Section 6.6,

Brushes.

2-221

R13929-7

Figure 6-9 Rotor Resistance Check

Loading...

Loading...