11.13

Section 11

Reassembly

11

Figure 11-47. Cylinder Head Screws Torquing

Sequence.

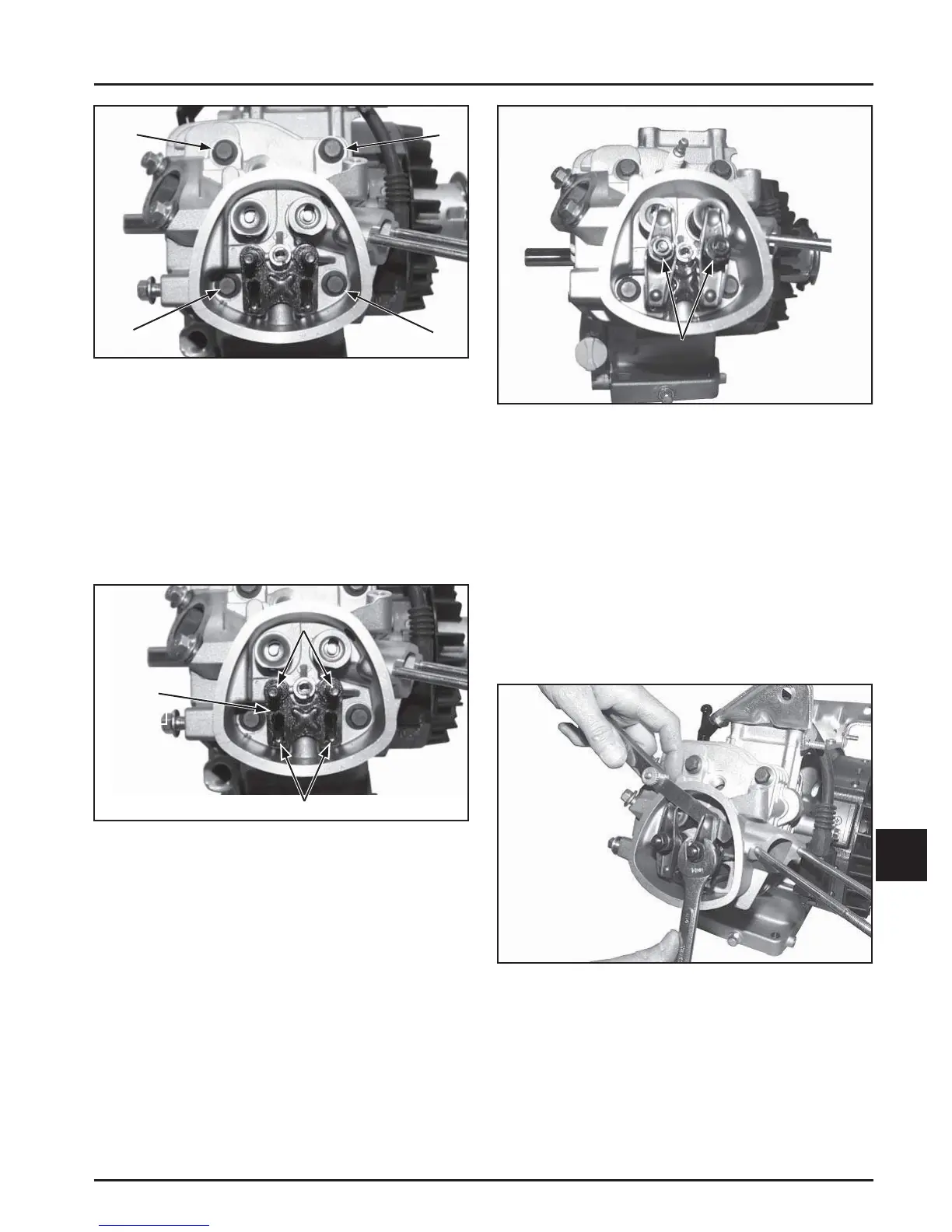

Install Push Rods and Rocker Arms

NOTE: Push rods should always be installed in the

original location.

1. Identify the proper position of each push rod.

Dip the ends of the push rods in engine oil and

install them in their respective locations, seating

each into the tappet socket. See Figure 11-48.

3

1

4

2

Figure 11-48. Installing Push Rods.

2. Install the push rod guide plate, aligning

the holes for the rocker arm studs. Screw in

the rocker arm studs and torque to 13.6 N·m

(120 in. lb.).

3. Assemble the rocker arms, adjusters, and

locknuts onto the studs and push rods. Finger

tighten the rocker arm pivot jam locknuts. See

Figure 11-49.

Guide

Plate

Rocker Arm

Studs

Install Push Rods

Figure 11-49. Installing Rocker Arms, Adjusters

and Locknuts.

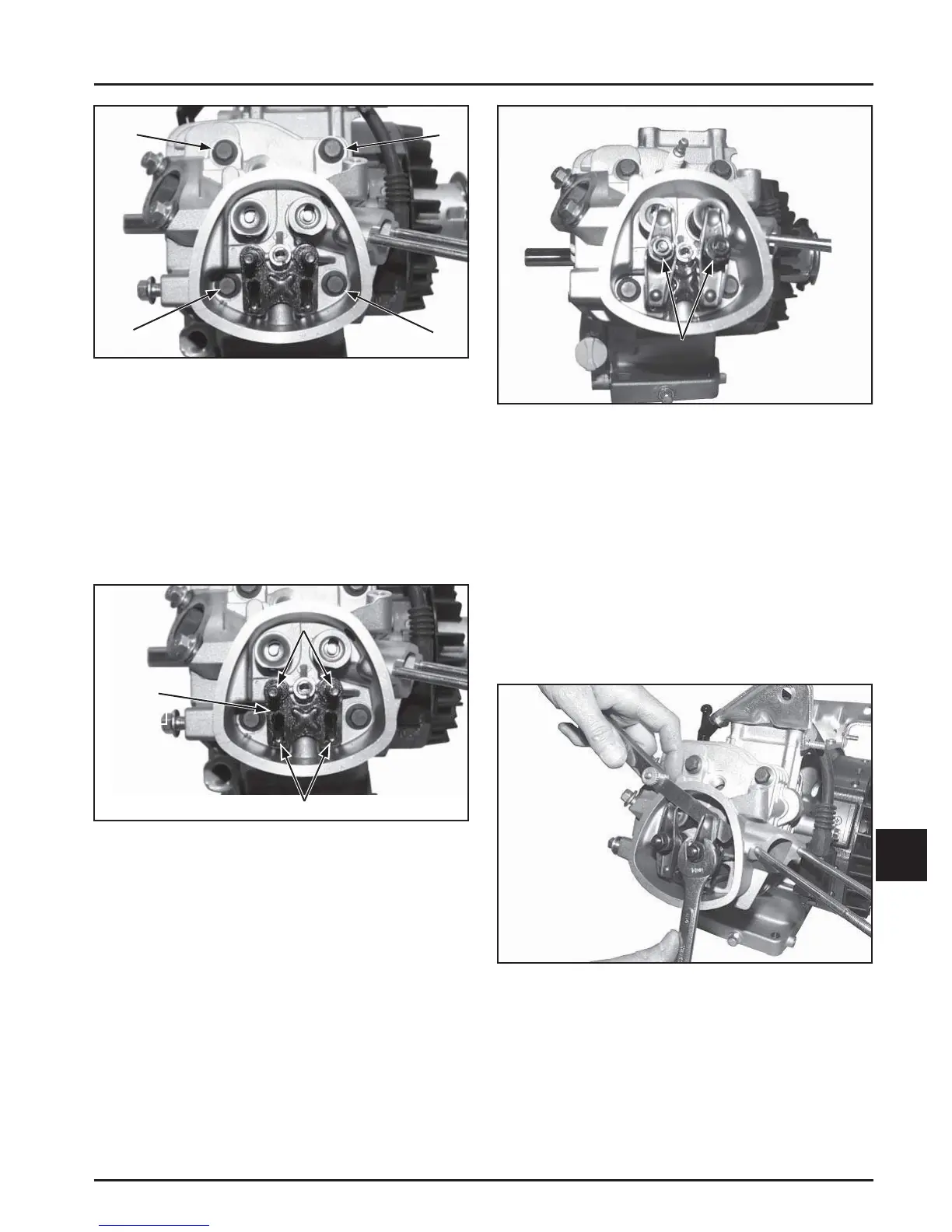

4. Adjust the valve tappet clearance as follows:

a. Make sure the piston is still at the top of the

compression stroke.

b. Insert a fl at feeler gauge between the rocker

arm and the valve stem. The recommended

valve to rocker arm clearance for both intake

and exhaust is 0.076-0.127 mm (0.003-0.005 in.)

(Cold). See Figure 11-50.

Figure 11-50. Adjusting Valve to Rocker Arm

Clearance.

c. Adjust clearance as required by loosening the

locknut and turning the adjuster.

Turn clockwise to decrease clearance.

Turn counterclockwise to increase clearance.

Jam

Locknuts

Loading...

Loading...