11.11

Section 11

Reassembly

11

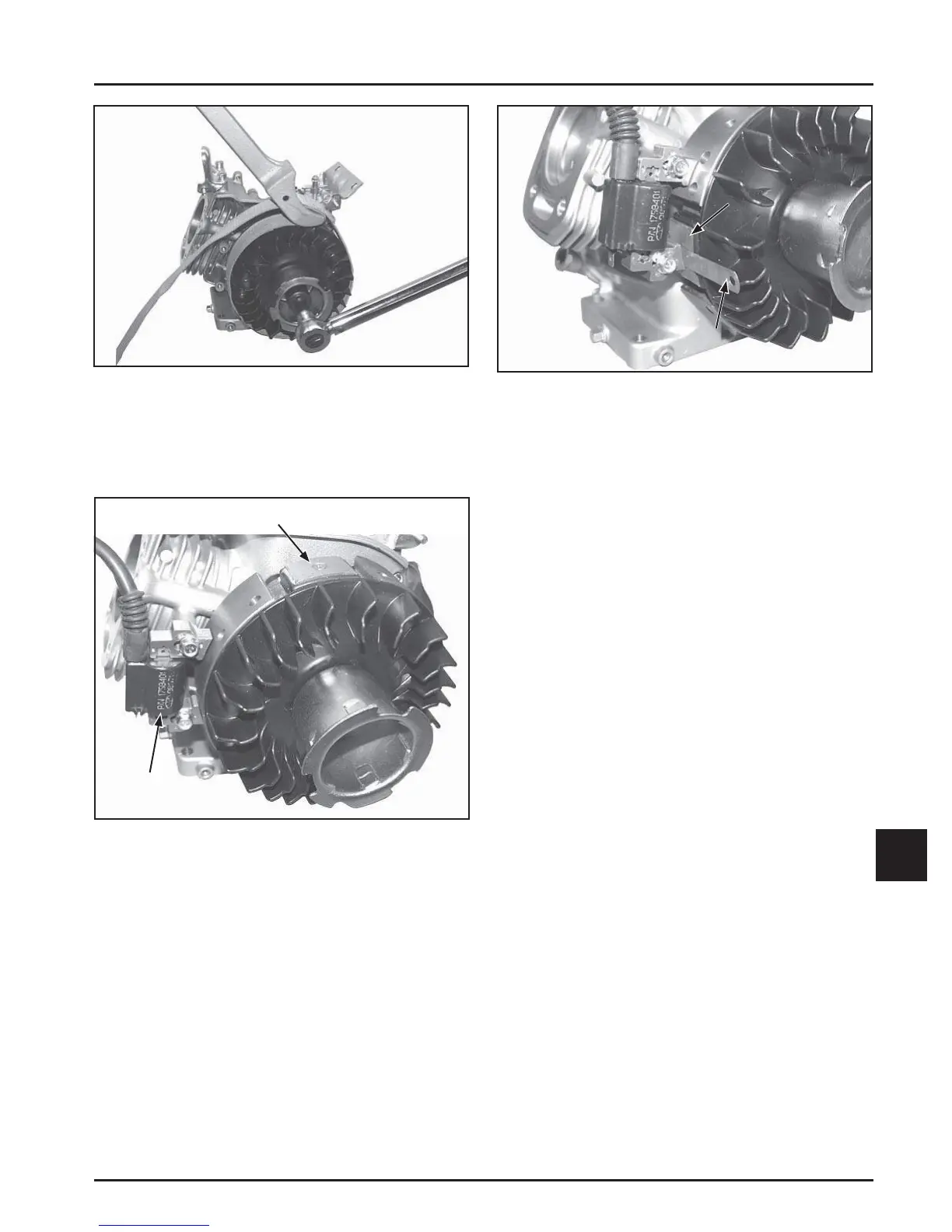

Figure 11-42. Setting Ignition Module Air Gap.

4. Insert a 0.254 mm (0.010 in.) fl at feeler gauge

between the leg of the module and the magnet.

Loosen the nearest screw allowing the magnet to

draw the module against the feeler gauge. Push

against the module to hold the leg tight against

the feeler gauge while tightening the screw. See

Figure 11-42.

5. Rotate the fl ywheel until the magnet is under the

other leg of the module. Loosen the nearest screw

allowing the magnet to draw the module against

the feeler gauge. Push against the module to

hold the leg tight against the feeler gauge while

tightening the screw.

6. Torque the fi rst hex fl ange screw, then the second

hex fl ange screw. Go back and torque the fi rst hex

fl ange screw one more time. Torque both module

screws to 10 N·m (89 in. lb.).

7. Rotate the fl ywheel back and forth, checking to

make sure the magnet does not strike the module.

8. Connect the kill wire to the ignition module

bo om blade terminal and route the wire lead to

the top of the crankcase. See Figure 11-43.

Magnet

Feeler

Gauge

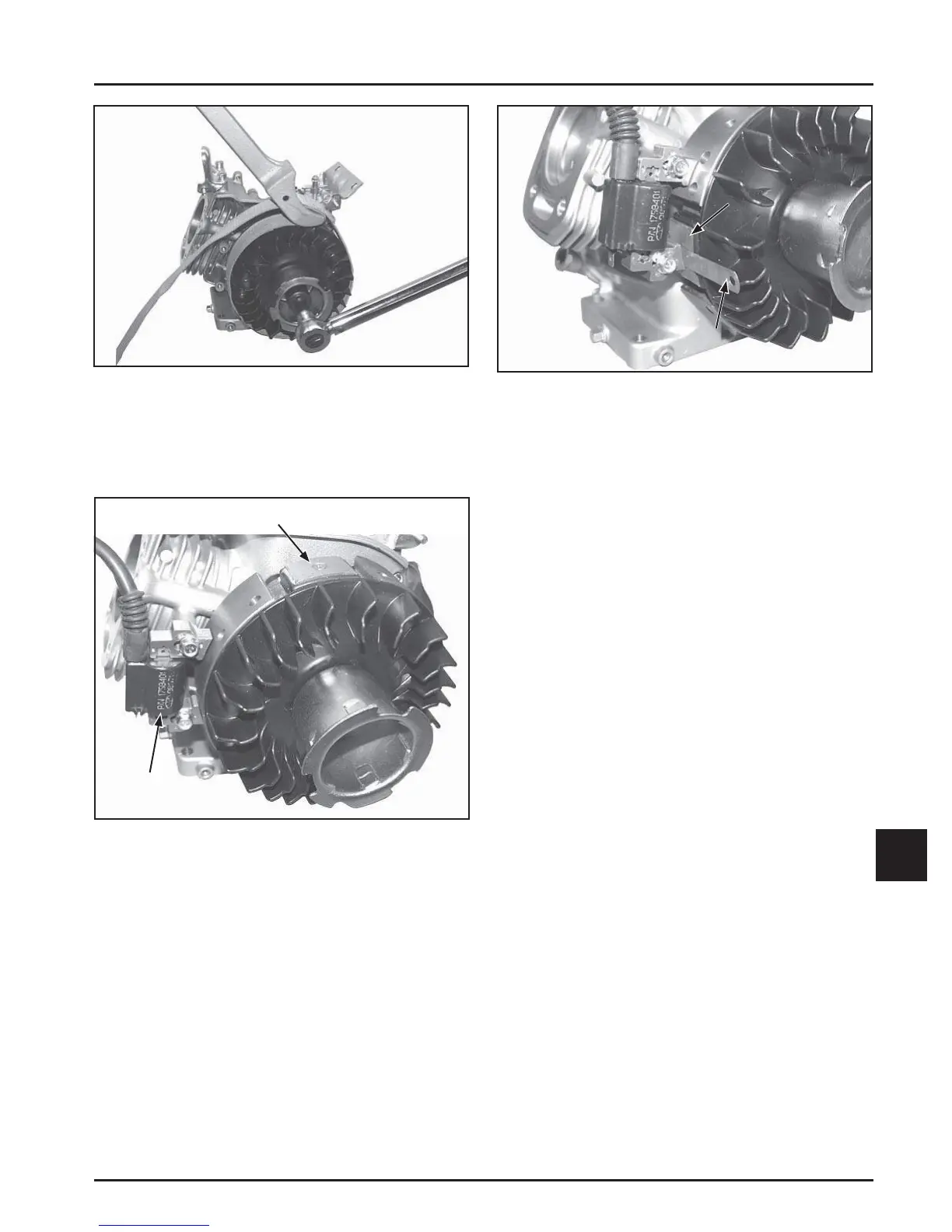

Figure 11-41. Install Ignition Module.

2. Install the ignition module loosely to the bosses

with the two hex fl ange screws. Move the module

as far away from the fl ywheel as possible, then

tighten the screws just enough to hold it in

position. See Figure 11-41.

NOTE: Ensure the ignition module is correctly

oriented.

3. Rotate the fl ywheel until the magnet is under one

leg of the ignition module. See Figure 11-42.

Initial Magnet Location

Initial Module

Location

Figure 11-40. Torque Flywheel Nut.

Install Ignition Module

1. Turn the fl ywheel so the magnet is away from

the location where the ignition module will be

installed. See Figure 11-41.

Loading...

Loading...