8.3

Section 8

Electrical System and Components

8

Electronic Ignition System

These engines are equipped with a dependable magneto breakerless ignition. In such a system, electrical energy

is generated by the cu ing of magnetic fl ux lines generated from the ignition magnet on the engine fl ywheel via

the prescribed air gap as it passes the ignition module. This energy is transferred through the ignition module

laminations and is then converted in the module electronics and stored in the module primary coil, as a current

if it is an inductive discharge ignition (IDI) module, or as a voltage in a compacitor if it is a capacitive discharge

ignition (CDI) module. The stored energy is transferred at the correct moment by triggering a semiconductor

switch inside the module. The electrical break by the switch initiates the energy transfer by causing the collapse

of the magnetic fi eld at the coil primary. This includes a voltage at the coil primary that is amplifi ed via

transformer action at the coil secondary. The amplitude of the voltage at the coil secondary is suffi cient to jump

the gap at the spark plug, igniting the fuel air mixture in the gap and initiating combustion. Note that by design,

these modules only will provide proper function if mounted in the correct orientation.

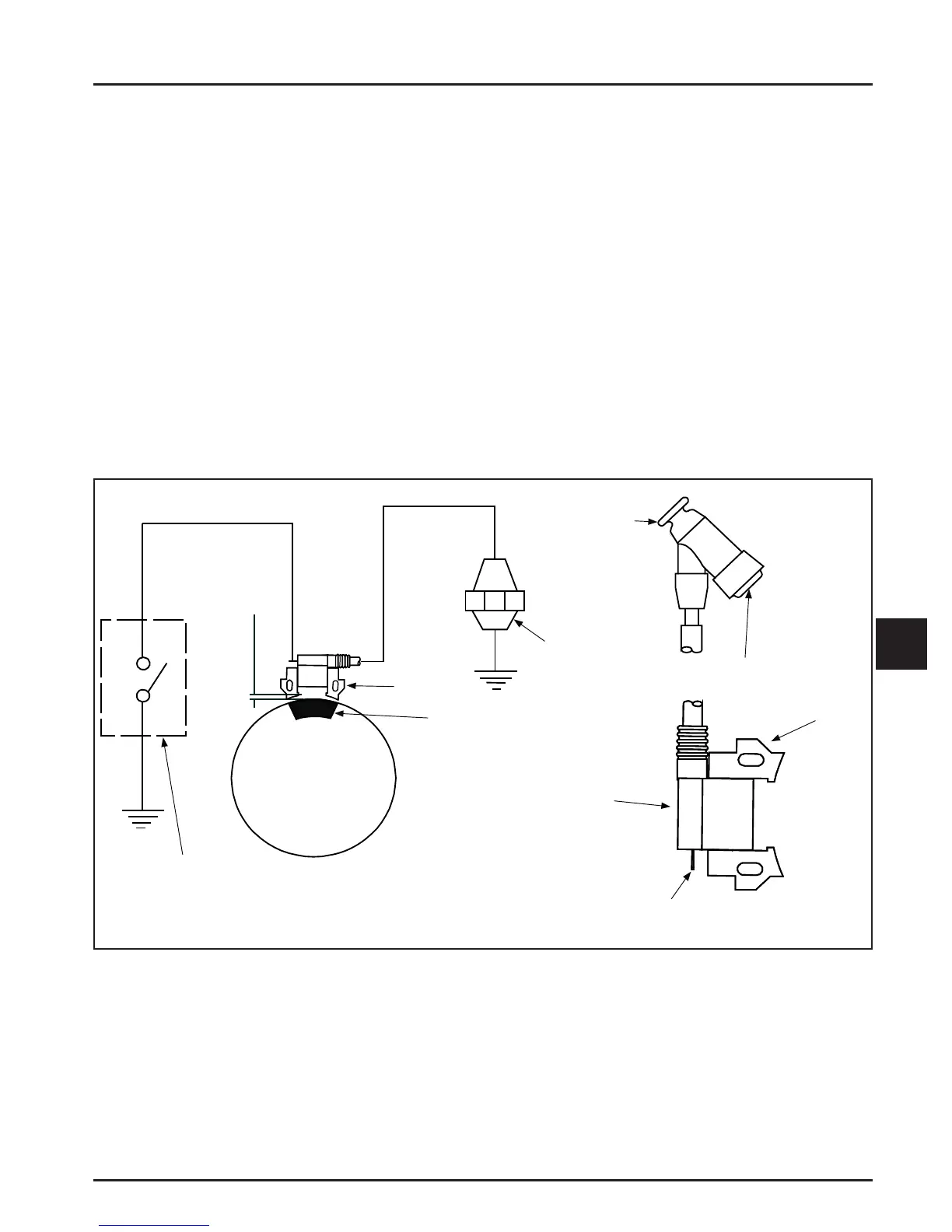

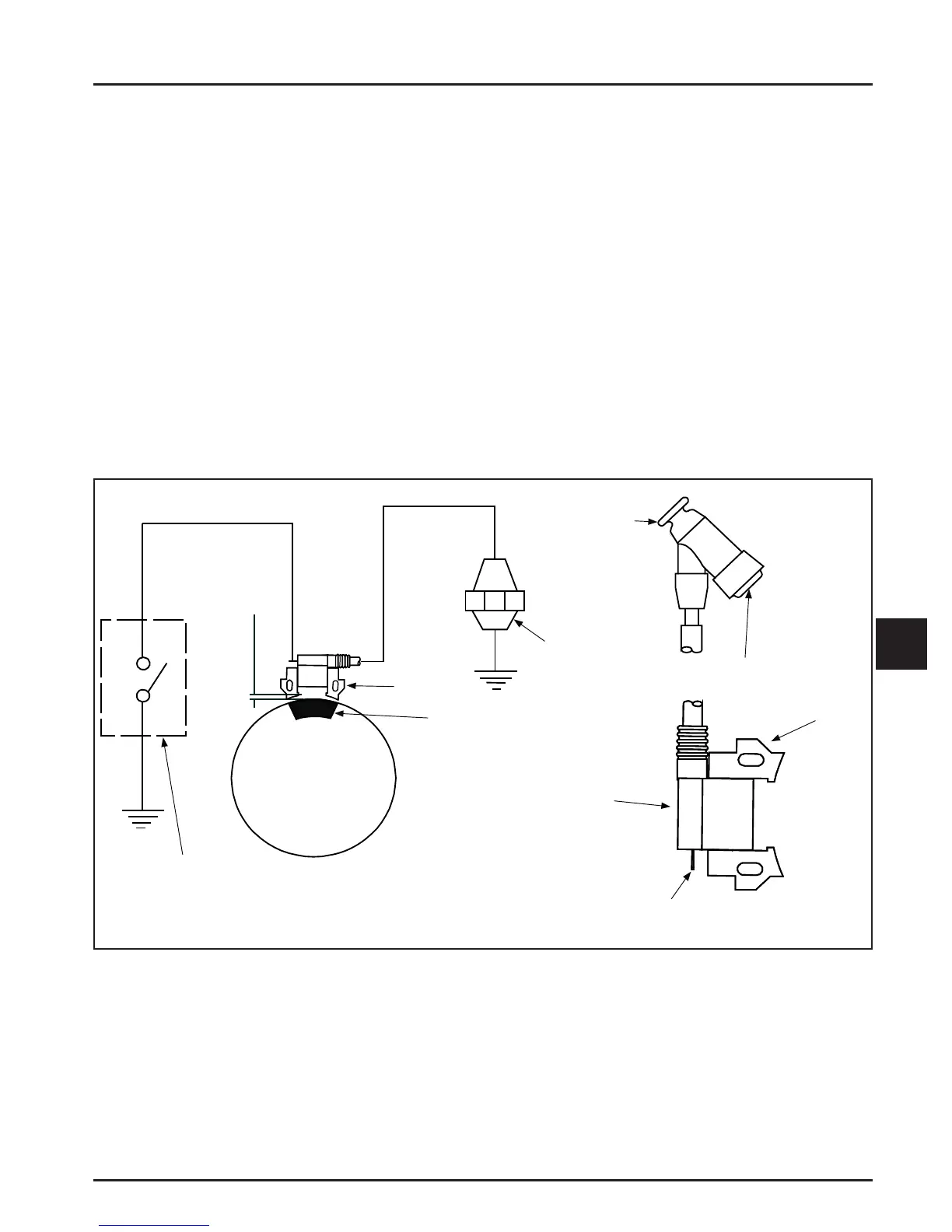

This system consists of the following components (see Figure 8-2):

● Magnets permanently affi xed to the fl ywheel.

● Inductive discharge ignition module (IDI) mounted on the engine crankcase.

● Includes a shut down (kill) terminal mounted at the side of the module.

● Includes a secondary lead wire from the coil to a terminal inside a spark plug boot.

● External switch that connects to the shut down terminal and grounds the module to stop the engine.

Spark Plug

Kill Switc h o r Of f

Position of Key Switch

Air Gap

0.254 mm

(0 .0 1 0 in.)

Flywheel

Magnet

Ig nition

Module

Kill Te rmina l

Ignition Module

(En larged View )

Spark Plug

Te r min a l

Lamination

Spark Plug Boot

Figure 8-2. Inductive Discharge Ignition System.

Troubleshooting and Testing Ignition

Ignition and Oil Sentry™ Systems

Ignition problems are most o en due to poor or loose

connections, or connections that keep the shut down

terminal shorted to ground preventing proper ignition

operation.

Before beginning any test procedures, be certain

all module terminal connections are correct and

fi t snugly. Make certain the shut down lead is not

shorted to ground when the engine is a empting

to crank or run. Proper ignition module air gap to

the fl ywheel magnet must be maintained for best

performance. Ensure crankcase oil is at the proper

level. Refer to Section 6.

Loading...

Loading...