133Section 8 Component Testing and AdjustmentTP-6356 4/12

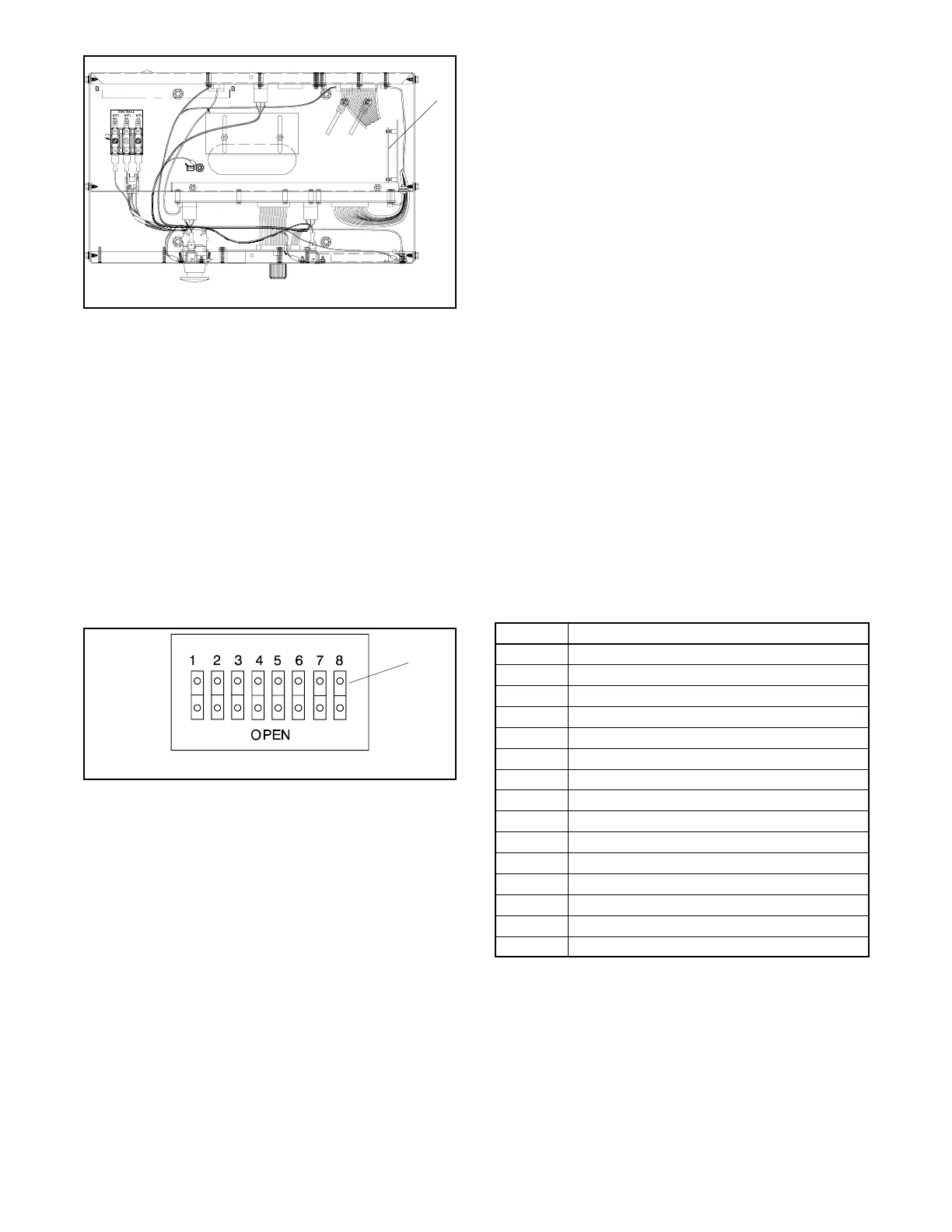

1

GM10193A-N

1. Pulse converter circuit board

Figure 8-17 Pulse Converter Circuit Board Mounting

in Decision-Makerr 550 Controller (top

view)

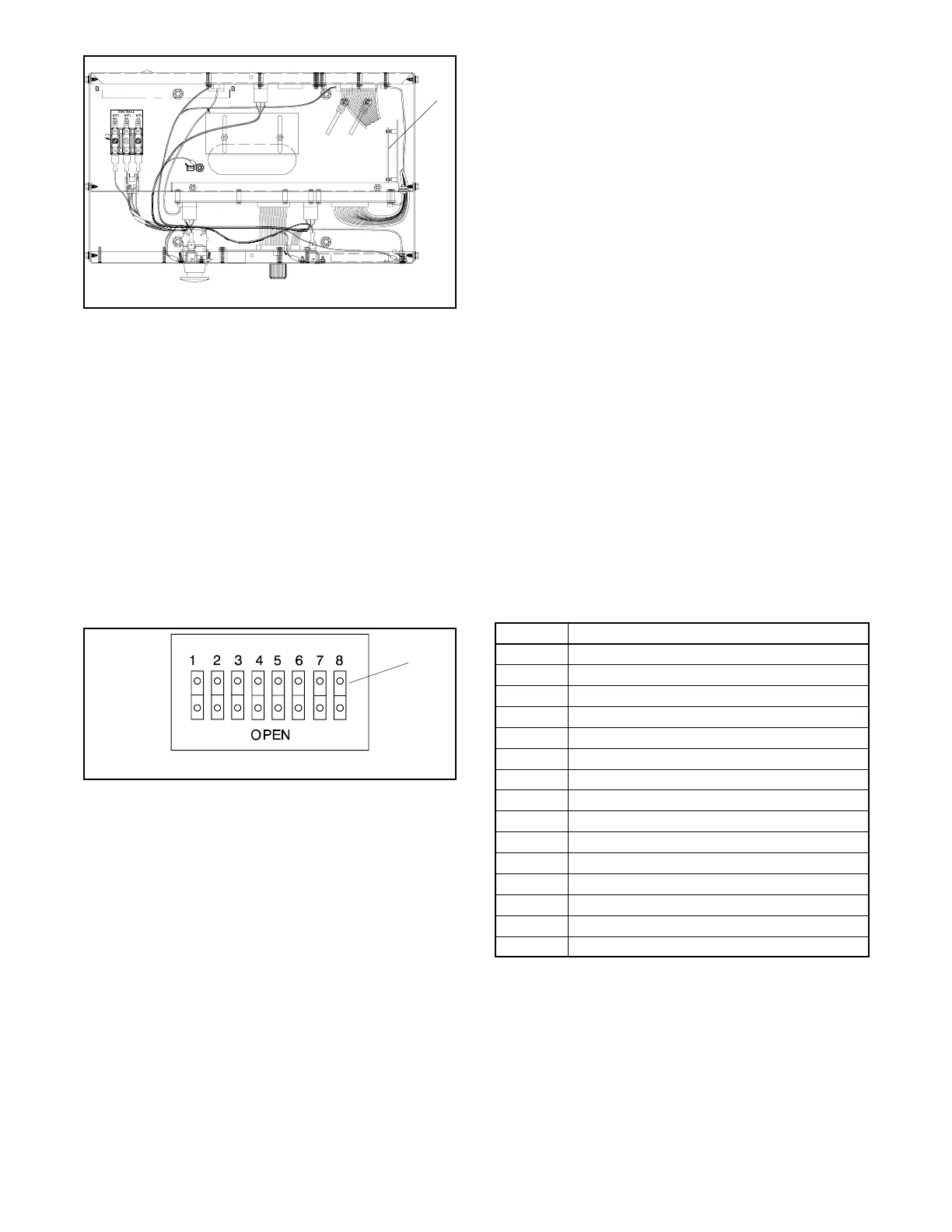

DIP Switch

Service technicians should be aware that odd number

tooth counts have an inherent percent error in engine

speed calculations. An even number of flywheel teeth

do not cause the percent error in speed. If the flywheel

has an odd number of teeth, the circuit board logic uses

acorrectionfactorasfollows:

(1 -- [tooth count] / [tooth count + 1]) x 100 = correction value

Use the circuit board DIP switch, see Figure 8-18 to

match the engine flywheel tooth number count.

6126

1. DIP switch closed position

1

Figure 8-18 DIP Switch Positions

Programming Shunt

Use programming shunt J1 across pins 1 and 2 on the

circuit board to get a 1:1 output. The shunt provides a

1:1 output regardless of the DIP switch selection. The

shunt is typically used with the 550 controller and is also

intended as a diagnostic test during troubleshooting.

Place J1 across pins 2 and 3 for a 2-pulse output signal.

Tach Output

The circuit board has a secondary output (P5-4) that

matches the input signal 1:1. Some generator set

models use this connection to eliminate an engine

speed sensor. See Figure 8-16 for P5-4 location.

Air Heater Control

The circuit board provides a 6-minute (ᐔ30 seconds)

signal pulsed on and off at 1 minute intervals to activate

the air heater after the start switch is toggled. If the start

switch signal is interrupted during the 6 minutes, the air

heater control signal is deenergized.

8.11.2 Anticipatory High Coolant

Temperature and Low Oil

Pressure Relays

The circuit board provides dry contacts for anticipatory

high coolant temperature (AHCT) and low oil pressure

(LOP) inputs for some generator set models.

LED Indicator

The red LED will flash at 1 Hz rate if the DIP switch

setting matches the engine flywheel tooth count and the

generator set is running at 60 Hz. The LED indicator

provides some diagnostic help. See Section 8.11.3,

Circuit Board Troubleshooting.

Circuit Board Connections

Figure 8-19 shows the connections made to the pulse

converter circuit board. Some generator set models

may not have all connections.

Plug-Pin Connection

P4-1 Low oil pressure input signal

P4-2 Battery positive (+) lead 70

P4-3 Anticipatory high coolant temperature input signal

P4-4 Cable shield (ground)

P4-5 Magnetic pickup sensor low (ground)

P4-6 Magnetic pickup sensor high

P5-1 Magnetic pickup output signal shield (ground)

P5-2 Speed signal output signal

P5-3 Speed sensor ground

P5-4 Tach output signal

P5-5 Magnetic pickup output signal (ground)

P5-6 V+ Speed sensor

P5-7 Low oil pressure output signal

P5-8 Anticipatory high coolant temperature output signal

P5-9 Air heater output signal

Figure 8-19 Pulse Converter Circuit Board

Connections

Loading...

Loading...