169Section 9 Gas Fuel SystemsTP-6356 4/12

9.5 Carburetor/Gas Mixer

Adjustment

Before adjusting the carburetor, verify that the engine

compression and ignition system meet specifications.

Do not adjust the carburetor to compensate for other

engine disorders. If the engine speed is incorrect, adjust

the governor to achieve 1800 rpm (at 60 Hz) or 1500

rpm (at 50 Hz). Adjust the mixer if governor adjustment

alone does not result in the desired engine speed.

Adjusting the carburetor affects the engine air/fuel

mixture. Routine carburetor adjustment is not

necessary. However, if the carburetor is removed or

tampered with, the mixer may require adjustment to

achieve optimum engine performance. Some engines

have sealed mixers that are not adjustable.

9.5.1 Gasoline Carburetor Adjustment

Procedure

Refer to the engine operation manual and/or engine

service manual for gasoline carburetor adjustment

information. Otherwise, use the following procedure to

adjust gasoline carburetor fuel system.

1. With generator set stopped, turn the main fuel and

idle mixture (if used) adjusting needles in

(clockwise) until they bottom lightly. Do not force.

2. Preliminary Setting: Turn main fuel adjusting

needle out (counterclockwise) 1 1/2--2 1/2 turns.

Turn the idle mixture adjusting needle (if used) out

(counterclockwise) 1/2--1 turn. See Figure 9-11.

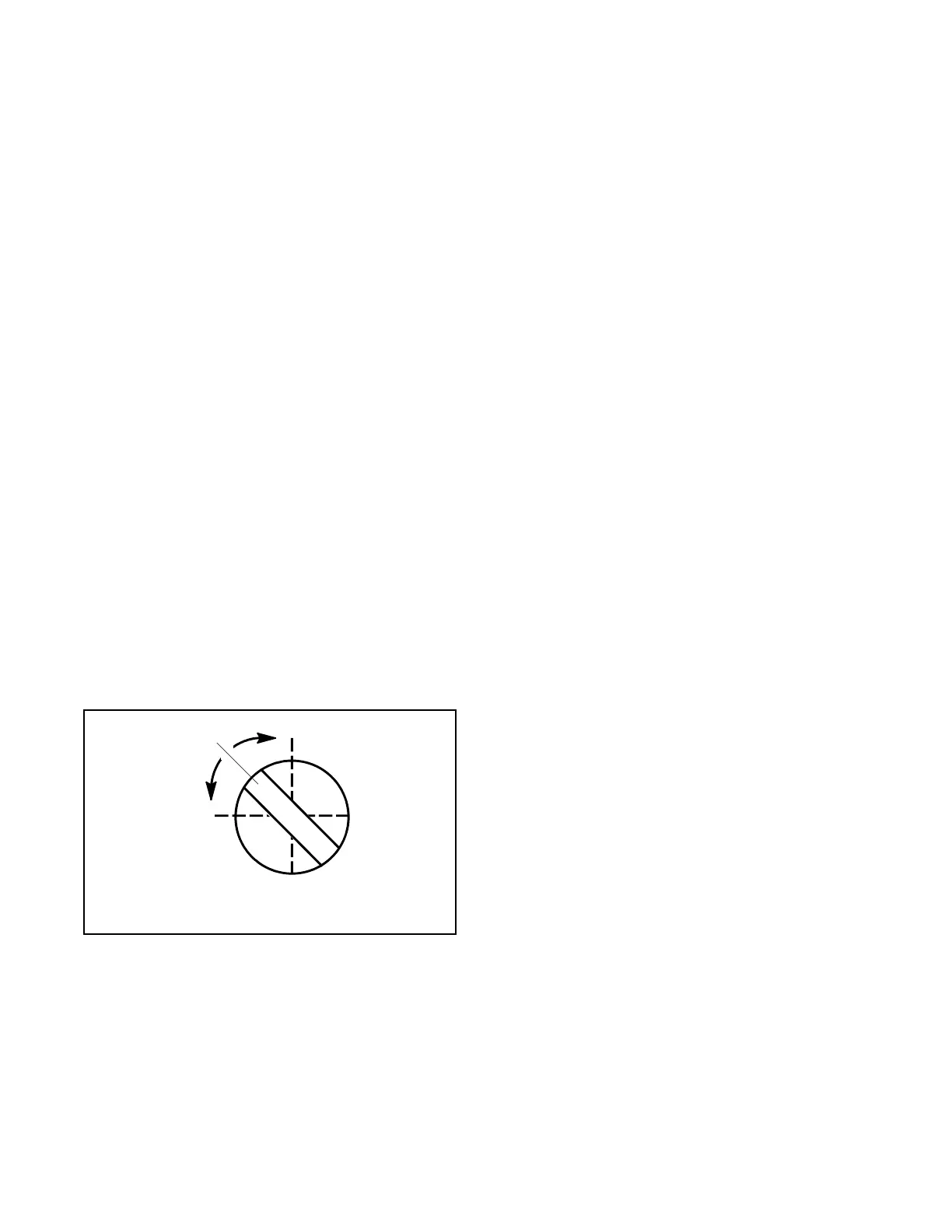

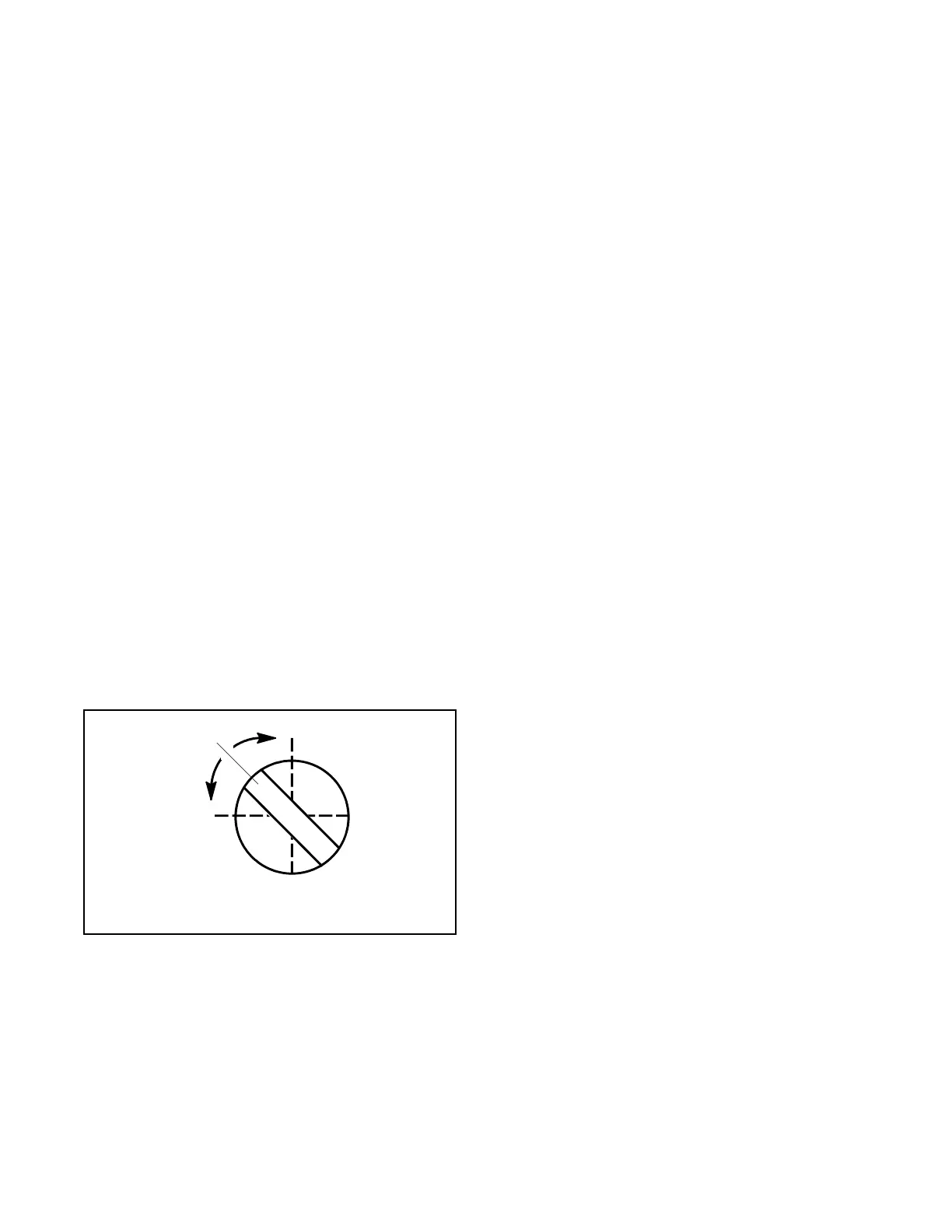

1

2

3

TP-5750-3

1. Fuel adjusting screw

2. Lean

3. Rich

Figure 9-11 Fuel Mixture Adjustment, Typical

3. Place the generator set master switch to the RUN

position to start generator set. Run at

approximately half load. The engine must be warm

before making final settings.

4. Apply 3/4 to full load to generator set.

5. Final Setting: Rotate the main fuel adjusting

needle until the engine runs smoothly at the leanest

setting and then turn the main fuel adjusting needle

out (counterclockwise) an additional 1/4 turn.

6. Place the generator set master switch to the

OFF/RESET postion to stop the generator set.

9.5.2 Gas Mixer Adjustment Procedure

(Typical)

Use the following procedure to adjust the gas mixer.

1. Place the generator set in the RUN position to start

the generator set. Run it at approximately half load.

2. Adjust the engine fuel mixture screw (Figure 9-11)

until the engine runs smoothly.

3. Apply varying loads and readjust the mixer as

necessary to achieve smooth engine performance

at all load levels.

4. Place the generator set master switch to the

OFF/RESET position to stop the generator set.

9.6 Fuel System Maintenance

9.6.1 Gasoline Models ( 20 kW, Ford

LRG-425 Powered only)

Clean or replace the fuel filter at the specified interval.

Service the filters more frequently if the engine runs

roughly, as a clogged fuel filter can cause rough engine

operation. Some models use a disposable inline fuel

filter, which must be replaced. Other models have a fuel

pump with an integral fuel filter that requires cleaning at

the specified interval.

9.6.2 Gaseous Models

Routine service items include draining water/sediment

from piping at petcock or pipe end cap, checking for fuel

leakage at pipe connections, checking flexible sections

for cracking or chafing, and keeping components clean

including fuel regulator vent holes.

A grease or wax residue tends to accumulate in the

piping and fuel regulators over time. If fuel system

problems persist, disassemble the fuel system

components and check for residue buildup. Remove

any residue with a brush and mild detergent.

Additional service for LP liquid withdrawal systems

include servicing the gas supplier or customer-supplied

LP gas filter.

Loading...

Loading...