179Section 9 Gas Fuel SystemsTP-6356 4/12

80--125 kW Models (8.1 L GM Engine). Use the

following procedure, except Step 5. Refer to the

respective specification sheet for generator set ratings

based on fuel selection.

1. Remove the generator set from service.

a. Place the generator set master switch in the

OFF position.

b. Disconnect the power to the battery charger, if

equipped.

c. Disconnect the generator set engine starting

battery(ies), negative (--) lead first.

d. Close all fuel supply valves.

2. Replace the gas mixer and regulator for LP gas

vapor (80--125 kW models only).

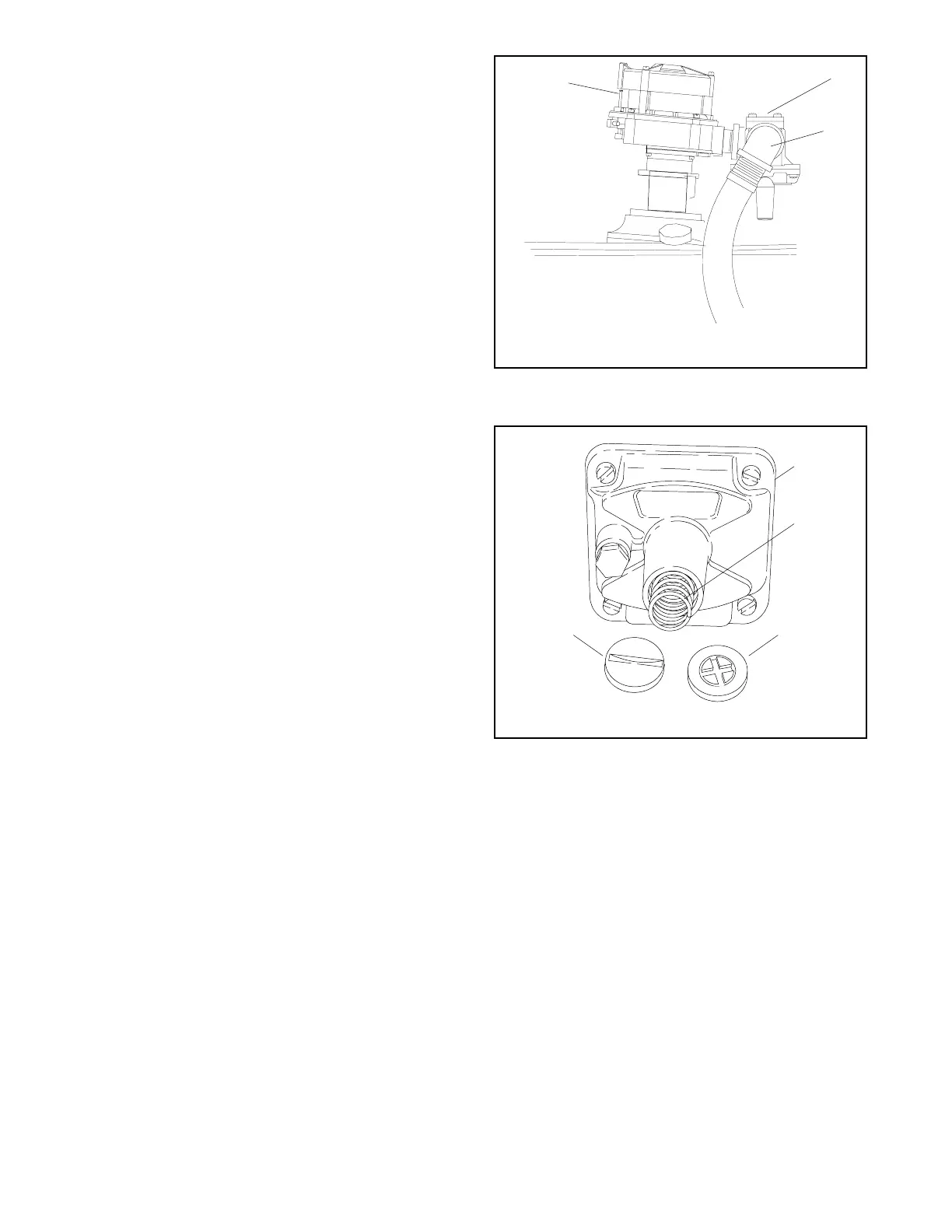

a. Remove the components from the engine as

shown in Figure 9-32.

D Remove the four screws attaching the gas

mixer to the throttle. The 80 kW has the

screw heads accessible from the bottom and

the 100/125 kW have the screw heads

accessible from the top. Retain the gasket

between the gas mixer and throttle.

D Disconnect the fuel line at the union

connector.

D Remove the supporting clamp between the

fuel regulator and mixer.

b. Disconnect the piping from the gas mixer inlet

and fuel regulator inlet and outlet.

c. Apply pipe thread compound to all male

threads and assemble the fuel system

assembly with the new gas mixer, reducer

bushing, and fuel regulator supplied in the kit.

d. Place the gas mixer on the throttle with the

existing gasket and install the four screws. See

Figure 9-34.

e. Reconnect the fuel line at the union connector.

3. Set up the fuel regulator for LP gas (30 kW model

with 3.0 L engine only).

a. Rotate the fuel regulator to a downward

pointing position as shown in Figure 9-34.

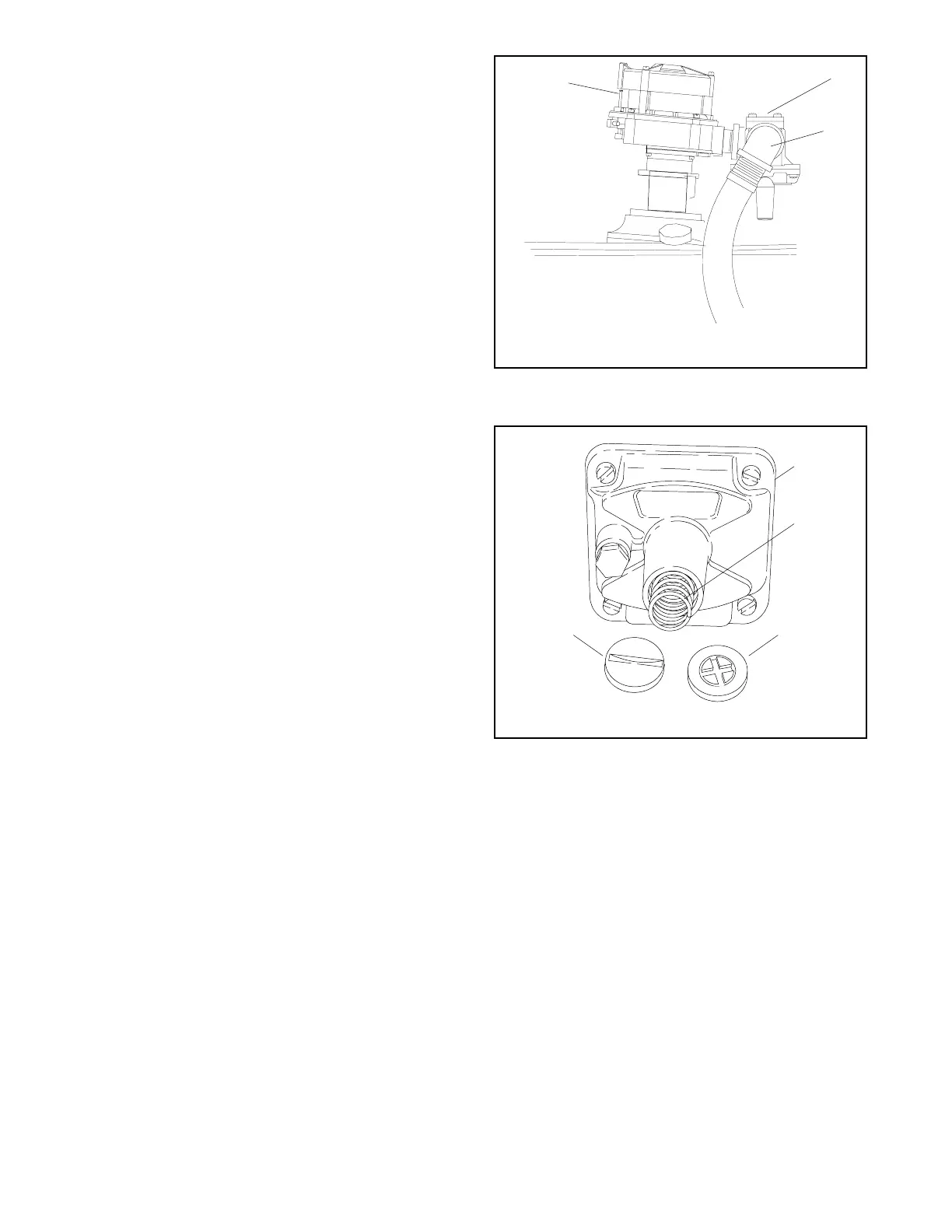

b. Remove the cover plug and adjustment screw

from the fuel regulator. See Figure 9-35.

GM14257-C

1. Fuel mixer

2. Fuel regulator (downward position)

3. Fuel line elbow

1

2

2

Figure 9-34 Fuel Mixer, Typical

SB-527

1. Fuel regulator

2. Spring

3. Adjustment screw

4. Cover plug

1

2

34

Figure 9-35 Fuel Regulator, Typical

c. Remove the spring. The spring will not be

reused.

d. Replace the adjustment screw to the

approximate midpoint of the adjustment range.

e. Replace the cover plug.

4. Change the fuel configuration jumper wire at

junction box terminal strip

Follow the procedure for the respective model.

See Figure 9-36 for a summary of all fuel

configurations requiring the TB12 terminal strip.

The fuel and frequency jumper connections on

TB12 is also available in the respective Wiring

Diagram Manual.

Loading...

Loading...