31. MAINTENANCE

4-28

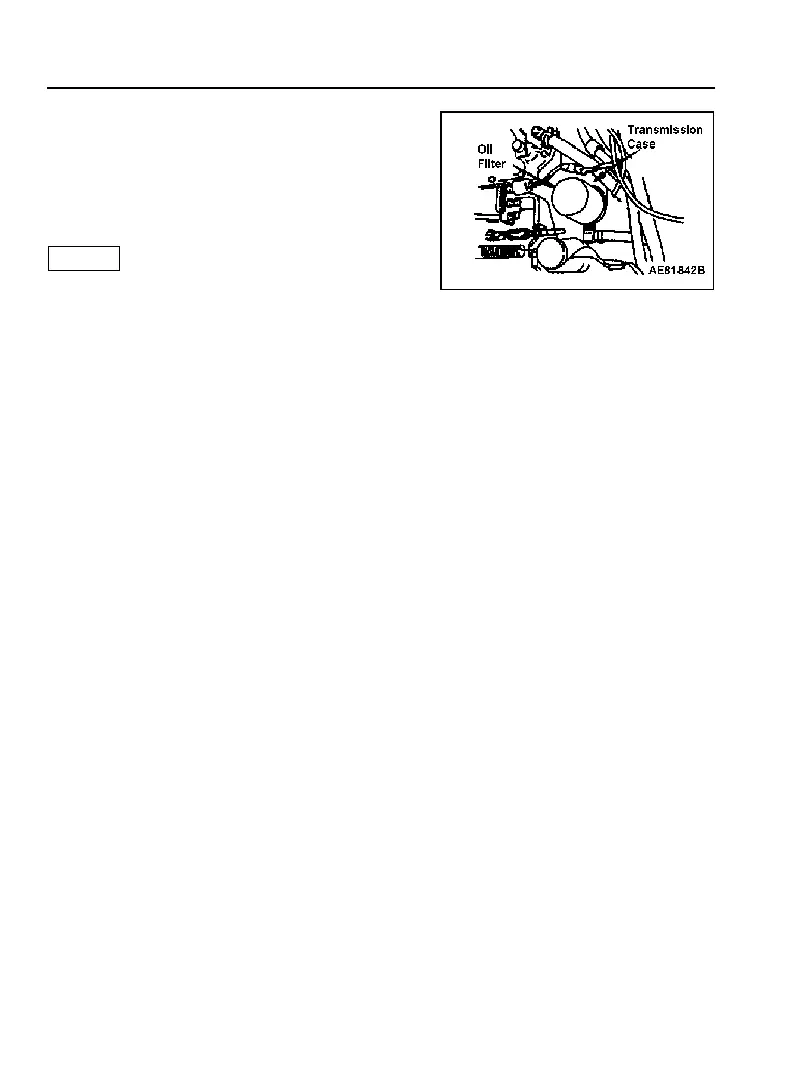

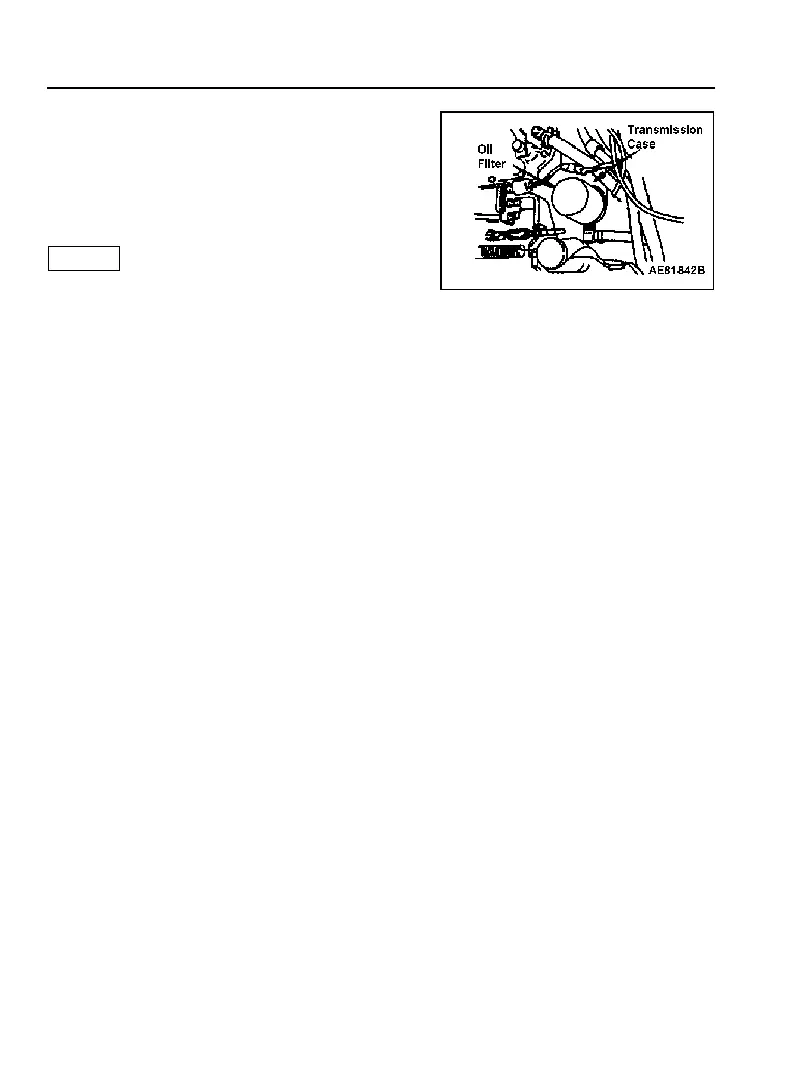

n CHANGE OIL IN TORQFLOW TRANSMISSION CASE (See

illustration)

See procedure on page 4-18.

n CLEAN TORQFLOW TRANSMISSION STRAINER

See procedure on page 4-18.

n REPLACE TORQUE CONVERTER OIL FILTER

Replace with genuine Komatsu Forklift oil filter.

n CHANGE CLUTCH OIL

31.7.2 BRAKE SYSTEM

n CHANGE BRAKE OIL/FLUID

31.7.3 ENGINE

n MEASURE COMPRESSION PRESSURE

n (DIESEL ENGINE) CHECK, ADJUST FUEL INJECTION TIMING, CHECK AND INSPECT FUEL INJECTION

NOZZLES

n (GASOLINE ENGINE) CHECK PCV BLOW-BY GAS REDUCTION SYSTEM FOR CLOGGING, DAMAGE

n CLEAN INSIDE OF COOLING SYSTEM

See “CLEAN INSIDE OF COOLING SYSTEM” on page 4-22.

31.7.4 HYDRAULIC EQUIPMENT

n CHANGE OIL IN HYDRAULIC TANK, REPLACE HYDRAULIC LINE FILTER, CLEAN HYDRAULIC TANK

STRAINER, CLEAN INSIDE OF HYDRAULIC TANK

See procedure on page 4-15.

31.8 EVERY 2,000 HOURS SERVICE

n (DIESEL ENGINE) CHECK AND ADJUST FUEL INJECTION TIMING

Perform this operation to maintain compliance with EPA Diesel Engine Exhaust regulations.

n (LPG ENGINE) REPLACE AIR VALVE DIAPHRAGM ON MIXER, REPLACE O-RING FOR LPG TANK

VALVE

31.9 EVERY YEAR OR EVERY 2,400 HOURS SERVICE

31.9.1 BRAKE SYSTEM

n CHECK OPERATION OF BRAKE MASTER CYLINDER, CHECK FOR OIL LEAKAGE, DAMAGE AND

WEAR

n CHECK OPERATION OF WHEEL CYLINDERS, CHECK FOR OIL LEAKAGE, DAMAGE & WEAR

n CHECK OPERATION OF BRAKE DRUM, CHECK FOR DAMAGE AND WEAR

n CHECK BRAKE LININGS FOR WEAR

n CHECK OPERATING CONDITION OF BRAKE SHOES

n CHECK BRAKE ADJUSTMENT LEVER AND RATCHET FOR WEAR AND DAMAGE

n CHECK BRAKE SPRINGS FOR DETERIORATION

n CHECK BRAKE BACK PLATES FOR DEFORMATION AND CRACKING, CHECK MOUNTING CONDITION

n CHECK AIR TIGHTNESS OF BRAKE PIPING/TUBING

31.9.2 TRAVEL SYSTEM

n CHECK AXLE FOR DEFORMATION, CRACKING AND DAMAGE

Loading...

Loading...