32. REPLACEMENT PROCEDURES

4-32

32.2 REPLACING TIRES

1. Stop the lift truck on a flat, safe area and apply the parking brake.

2. Chock the wheel diagonally across from the wheel to be replaced.

3. Using a lug wrench, loosen the lug nuts until they can be turned by hand.

4. Place the jack on the jacking point and raise the lift truck up until

the wheel to be replaced clears the ground.

5. Remove the lug nuts, then remove the wheel.

6. Install the replacement wheel on the hub and hand tighten the lug

nuts to hold the wheel in place.

7. Tighten the lug nuts again with a lug wrench, using a diagonal

“criss-cross” pattern, ensuring that the wheel is snugly in place,

but not fully tightened.

8. Let the jack down slowly to lower the lift truck. Tighten the lug

nuts to the specified torque. (See “SERVICE DATA” on page 4-6

for specified torque.)

9. Adjust the tire inflation pressure to the set pressure.

(See “SERVICE DATA” on page 4-6 for details of the set inflation

pressure.)

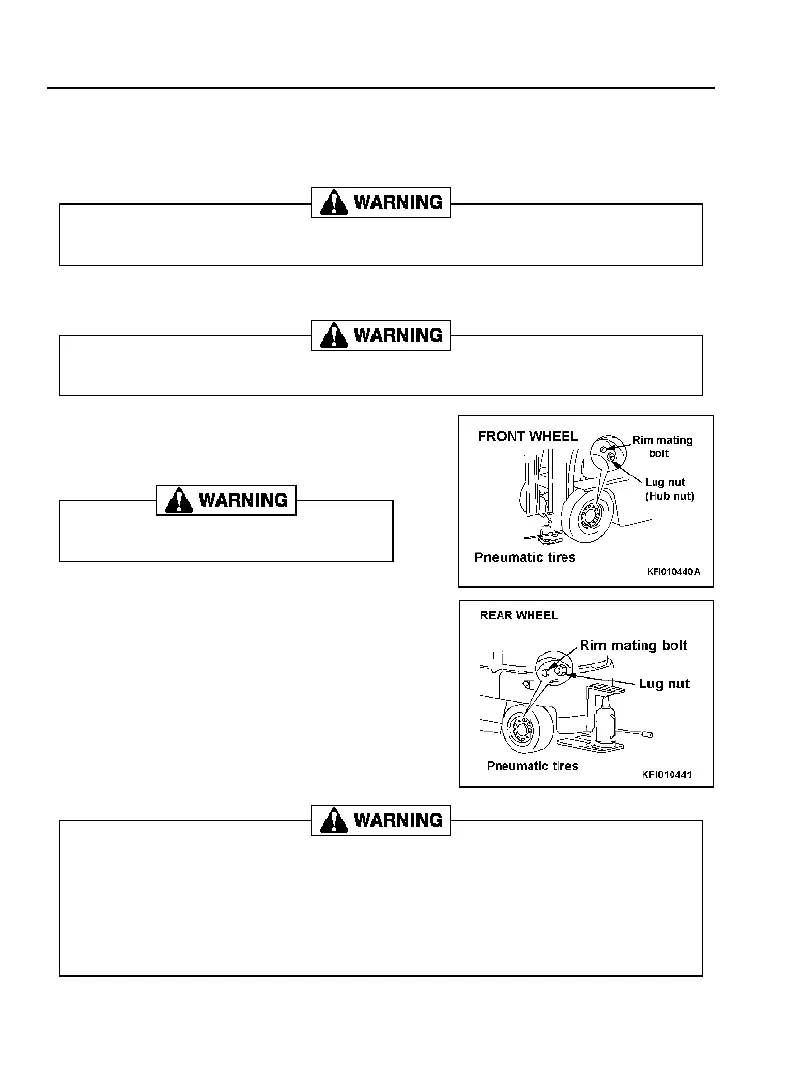

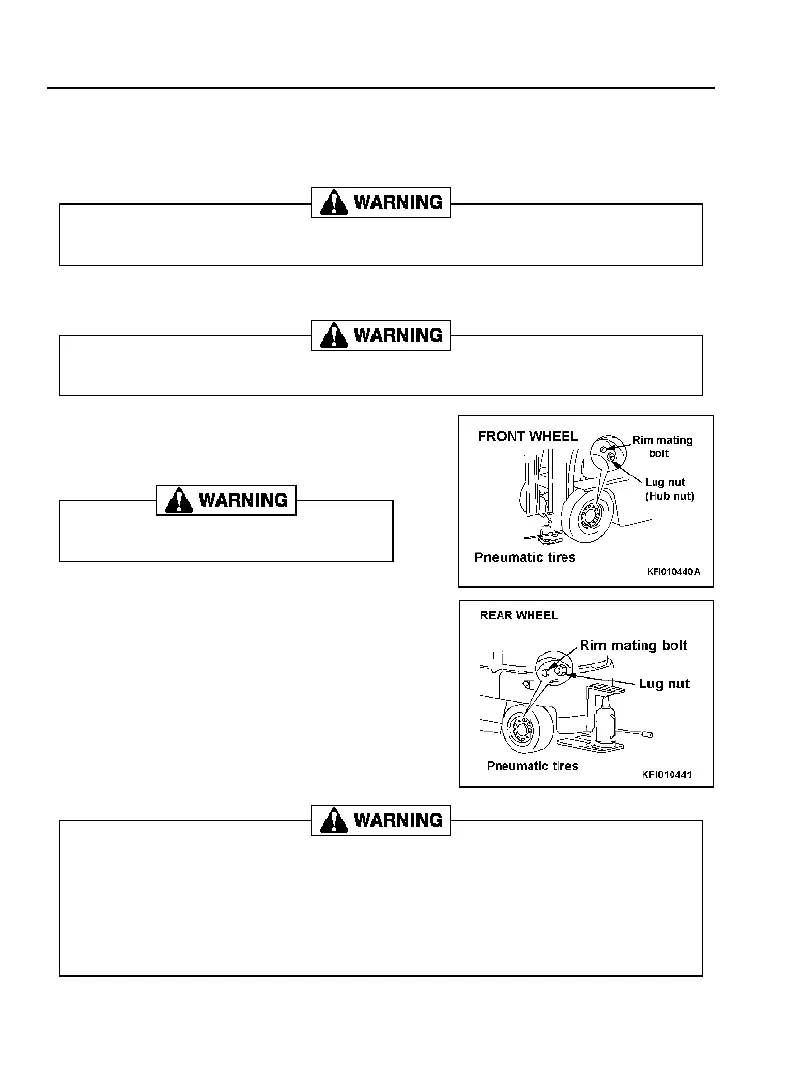

• After confirming that the rim mating bolts are tight, loosen the lug nuts (hub nuts).

• NEVER loosen the rim mating bolts by mistake.

Jack up the fork lift truck after confirming that the jack will not slip. NEVER enter under the body of the

fork lift truck.

Ask a tire and wheel specialist to carry out

disassembly and assembly of tires and wheels.

• Always ask a specialist to carry out disassembly of the tires, tubes and rims, and for inflation

of the tires. The tires used on forklift trucks are at a high inflation pressure, so operations with

tires are extremely dangerous.

• The tires are inflated to a high pressure, so deformed or cracked rims are extremely

dangerous. Check carefully before inflating tires. NEVER use tires with deformed or cracked

rims.

• Before inflating the tires, adjust the pressure of the air compressor to the correct set pressure

so that the tires are not inflated above the set pressure.

Loading...

Loading...