ATTACHMENTS, OPTIONS HANDLING HYDRAULIC RIPPER

6-5

OPERATION

INSPECTION AND ADJUSTMENT BEFORE STARTING ENGINE

Walk-around check

1. Check for wear of the point at the tip of the shank, check the mounting condition, and check for damage to

the rivets. If any abnormality is found, replace or repair.

PRECAUTIONS WHEN OPERATING

● Travel in low speed and lower the ripper gradually when starting to move the machine off. When the optimum

digging depth is reached, move the control lever to the HOLD position.

Do not dig the shank in deep when starting digging operations.

● During ripping operations, never turn the machine suddenly or travel in reverse. When turning the machine

suddenly or traveling in reverse, raise the shank from the ground surface.

● When carrying out digging operations with only one shank, always use the center shank. Remove both side

shanks.

● When starting to travel up a steep slope or when reaching the bottom of the slope, the point may touch the

ground. On hard ground, there is danger of the point breaking if it touches the ground, so raise the shank to

the maximum height.

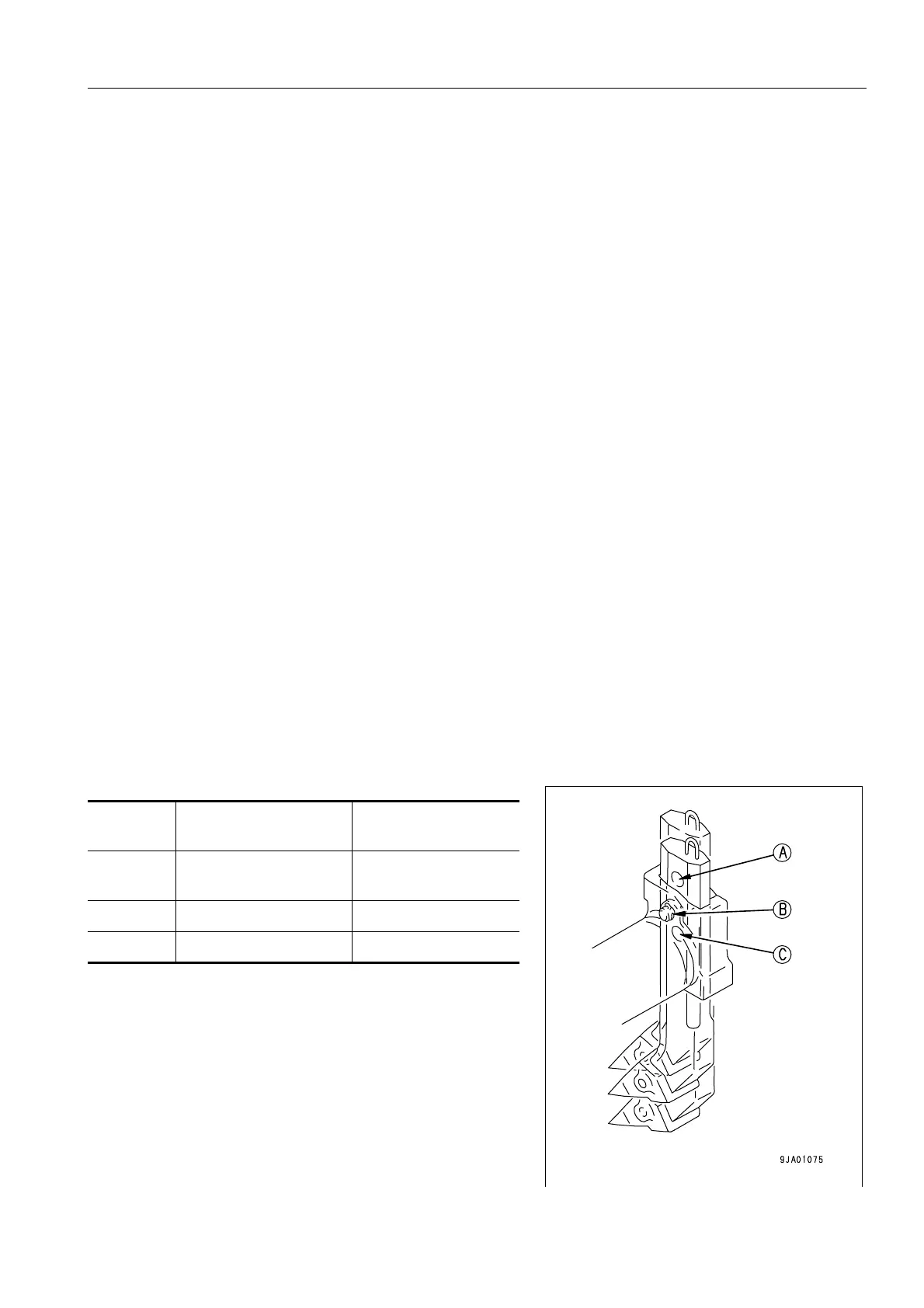

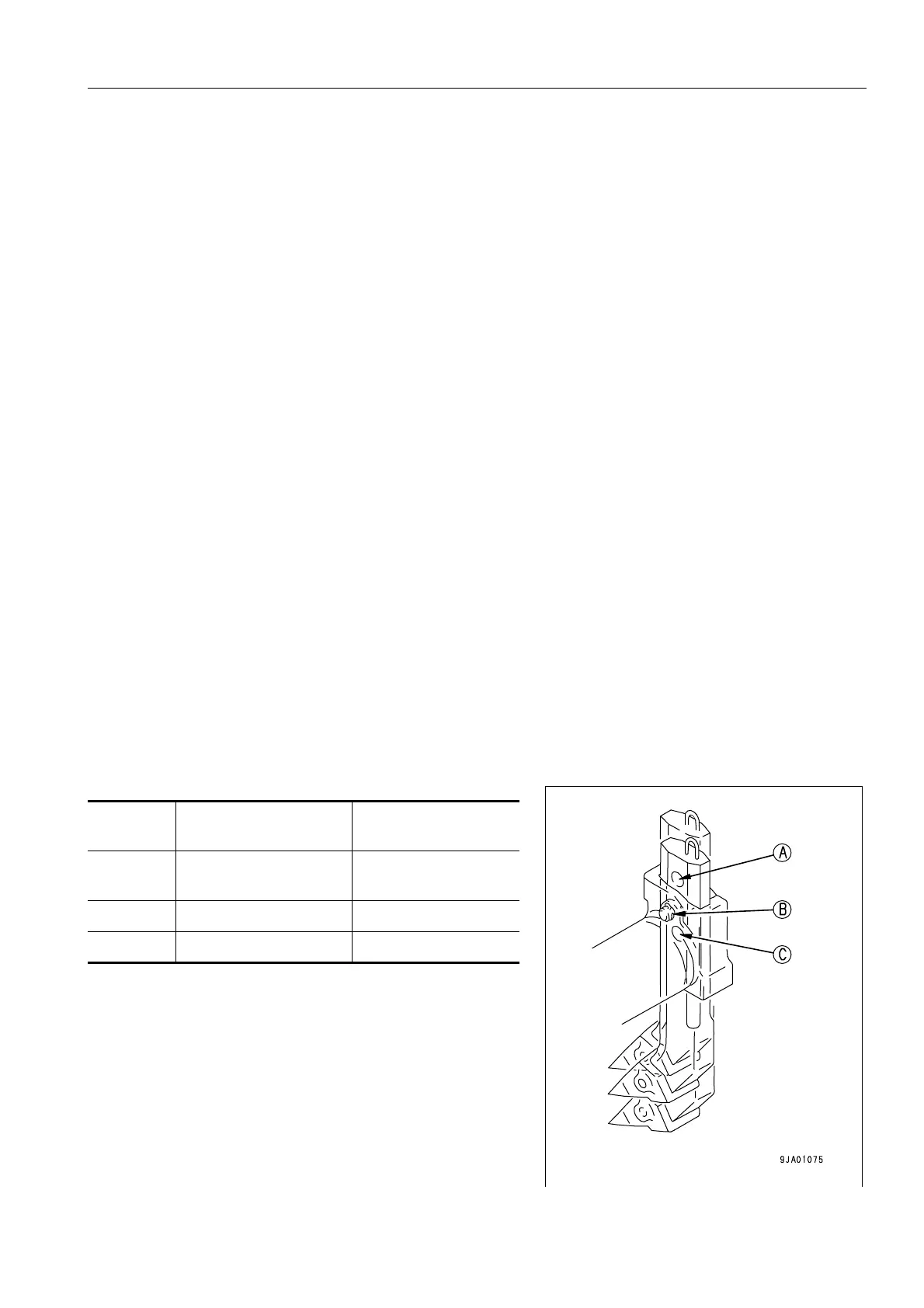

ADJUSTMENT OF WORK EQUIPMENT

ADJUSTMENT OF DIGGING DEPTH

There are mounting holes for the pin in the shank. Select the mounting hole to match the digging depth.

Pin hole

position

Use Max. digging depth

(A)

When there is special

need to dig deeply

665mm (2’22")

(B) Normal operations 555mm (2’22")

(C) When not using ripper -

Loading...

Loading...