16.

Install cover (8) on the bottom of the fuel tank. (if equip-

ped)

17.

After completing the replacement of filter cartridge (4),

bleed air from the fuel circuit.

REMARK

For the procedure to bleed air, see “PROCEDURES FOR

BLEEDING AIR FROM FUEL CIRCUIT (3-256)”.

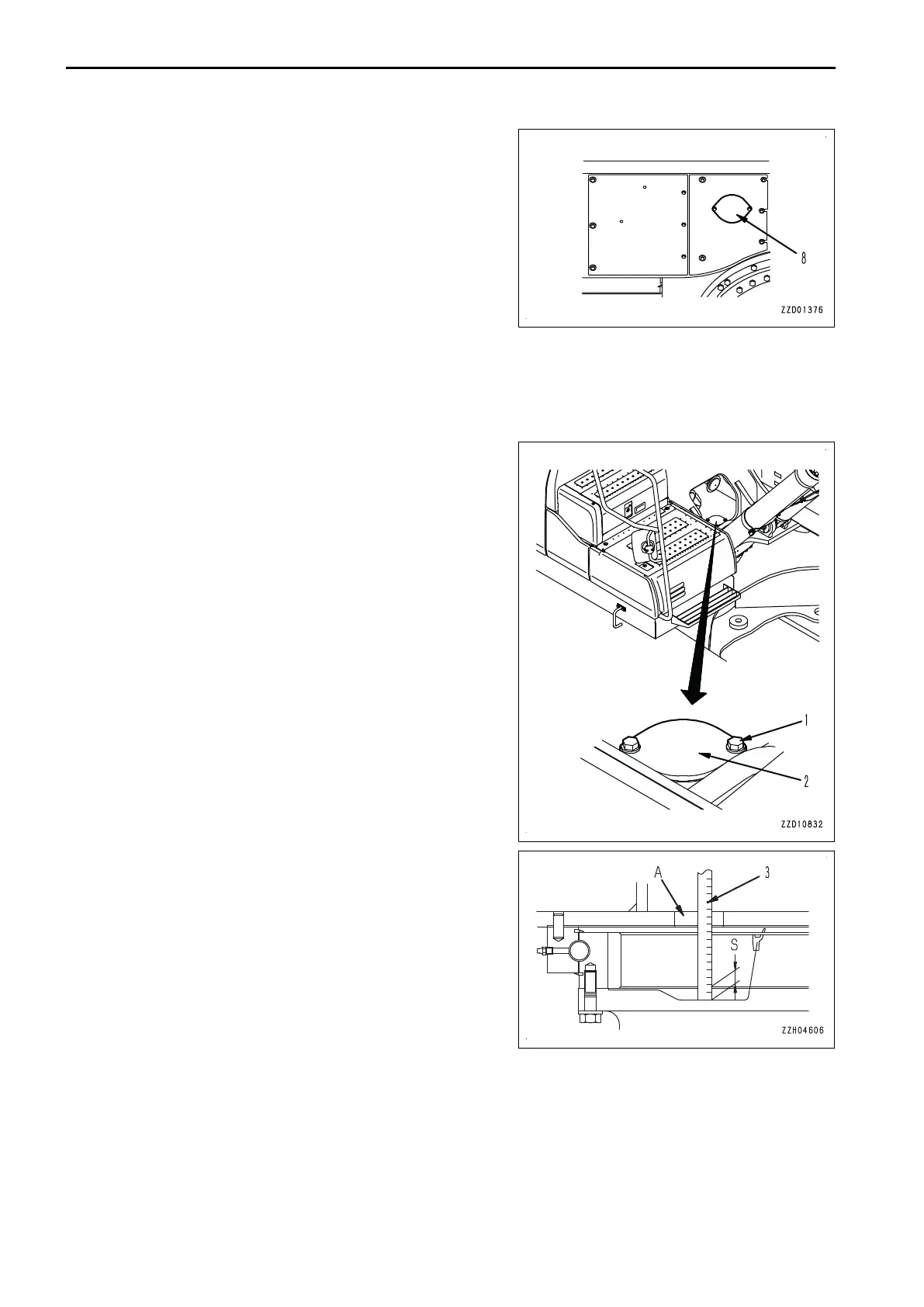

METHOD FOR CHECKING SWING PINION GREASE LEVEL, ADD GREASE

Items to be prepared

Scale

1.

Swing 3 times each to the right and left, and stop the machine.

2.

Remove bolts (1) (2 pieces) on the top of the revolving

frame, and remove cover (2).

3.

Insert ruler (3) into the grease through inspection and ad-

justment hole (A). Check that the height of grease (S) in

the area where the pinion passes is at least 20 mm.

Add grease if the grease amount (S) is less than 20 mm.

4.

Check that the grease is not milky white.

Total amount of grease: 33 ℓ(29.7 kg)

If the grease is milky white, it needs to be replaced. Ask

your Komatsu distributor to replace it.

5.

Install cover (2) with bolt (1).

MAINTENANCE PROCEDURE MAINTENANCE

4-52

Loading...

Loading...