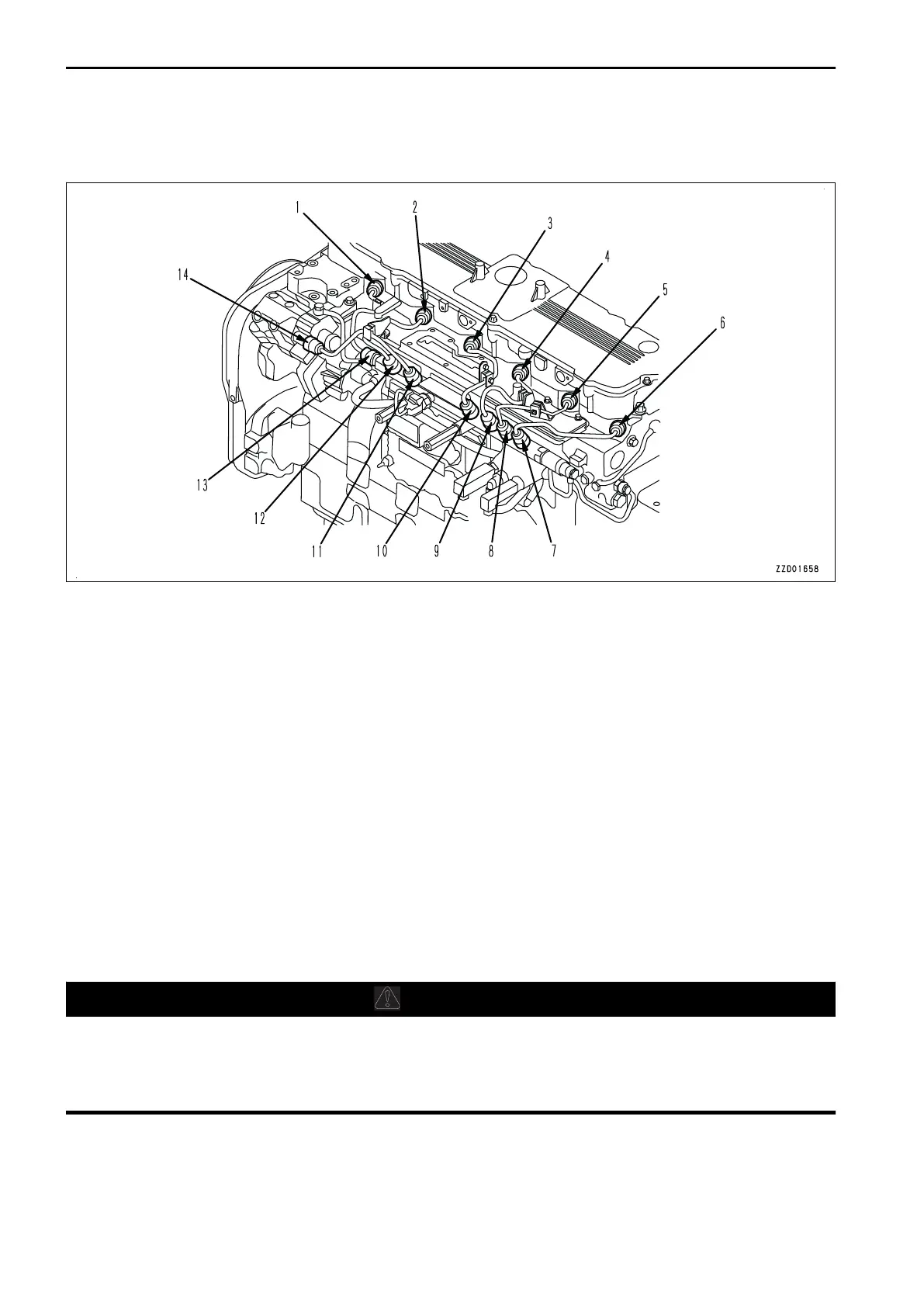

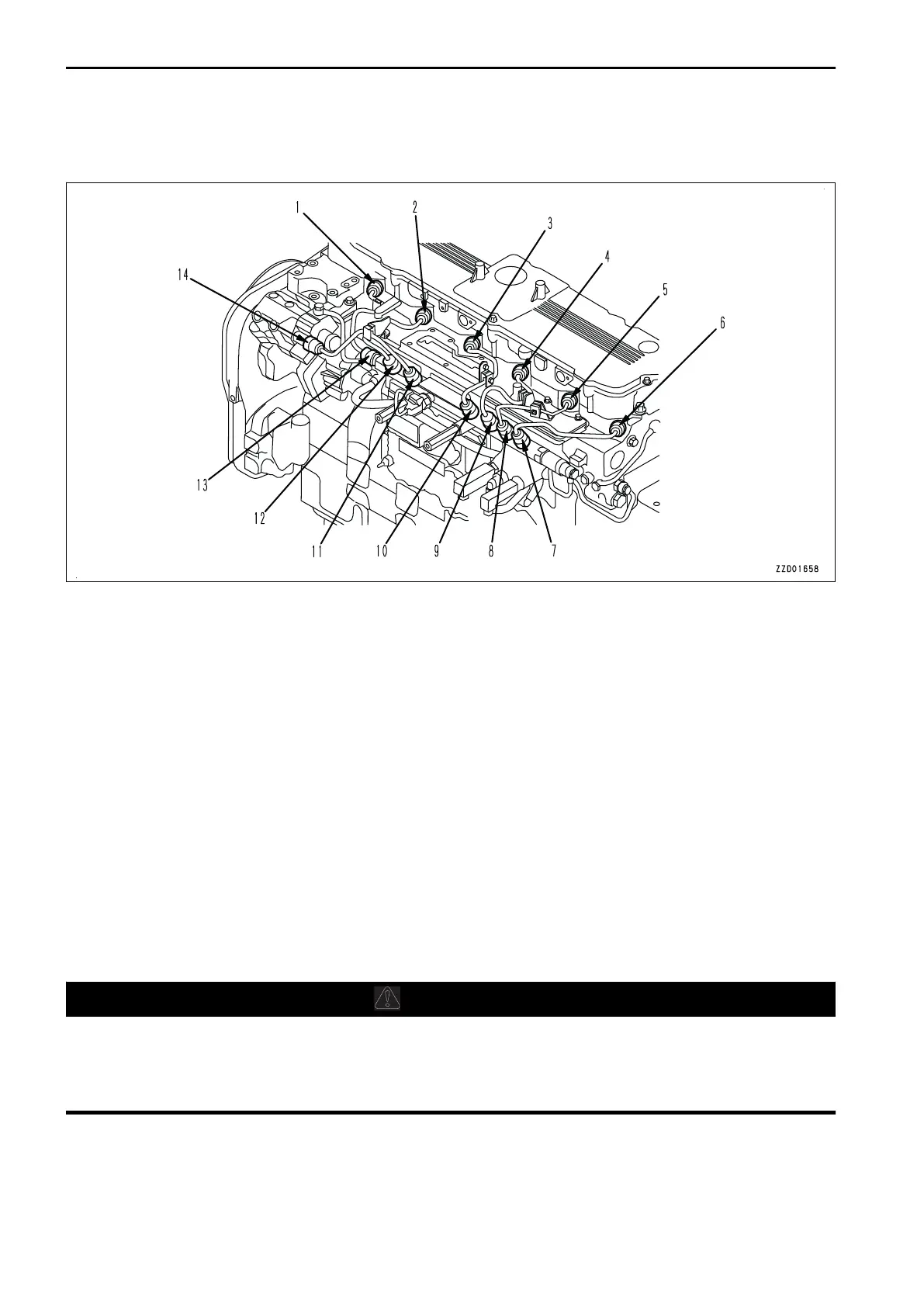

METHOD FOR CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP,

HARDENING OF RUBBER

Check fuel spray prevention caps (1) to (14) visually or with a finger to see if any of them has slipped off, or the

rubber portion is hardened.

REMARK

The fuel spray prevention caps (1) to (14) act to prevent the fuel from coming into contact with high-temperature

parts of the engine and causing a fire if the fuel should leak or spray out.

If there are any problems, the related parts must be replaced. Ask your Komatsu distributor for replacement.

EVERY 4500 HOURS MAINTENANCE

Maintenance for every 50, 250 and 500 hours should be performed at the same time.

METHOD FOR CLEANING KDPF

Contact your Komatsu distributor for cleaning of the KDPF.

METHOD FOR CLEANING DEF TANK

Ask your Komatsu distributor for cleaning of the DEF tank.

EVERY 5000 HOURS MAINTENANCE

Maintenance for every 50, 250, 500 and 1000 hours service should be performed at the same time.

METHOD FOR CHANGING OIL IN HYDRAULIC TANK

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Accordingly, wait until they have cooled down before starting the work.

• When removing the oil filler cap, the oil may spout out. Turn it slowly to release the internal pres-

sure, then remove it carefully.

NOTICE

If the machine is equipped with a hydraulic breaker, the hydraulic oil deteriorates faster than in the nor-

mal bucket digging operation. Accordingly, perform maintenance referring to “MAINTENANCE SCHED-

ULE (4-12)”.

MAINTENANCE PROCEDURE MAINTENANCE

4-78

Loading...

Loading...