METHOD FOR CHECKING OIL LEVEL IN SWING MACHINERY CASE, ADDING

OIL

WARNING

Immediately after the engine is stopped, its parts and oil are still very hot, and may cause burn injury.

Accordingly, wait until they have cooled down before starting the work.

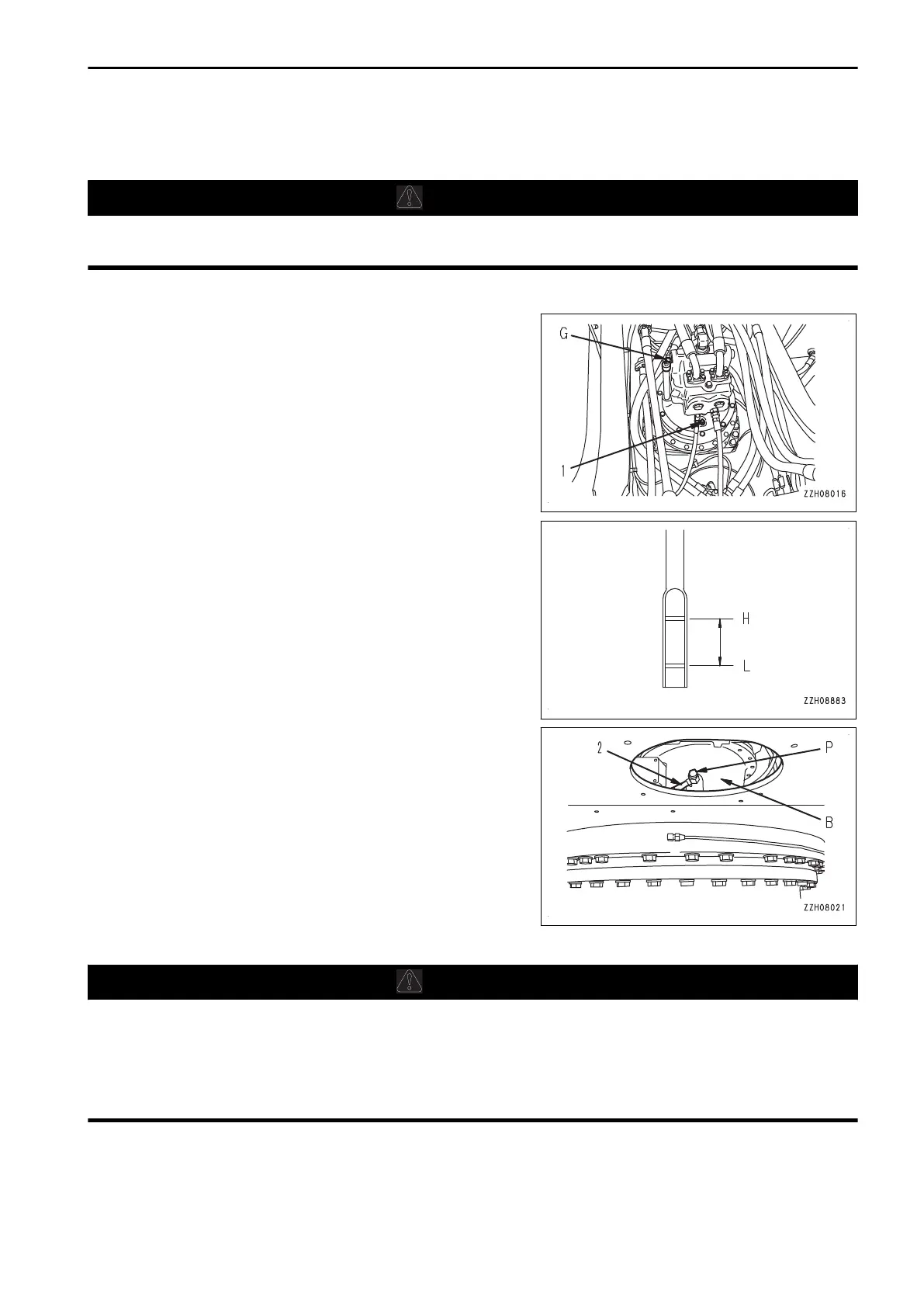

1.

Open the cover.

2.

Remove dipstick (G) and wipe off oil on it with a cloth.

3.

Insert dipstick (G) fully into the guide.

4.

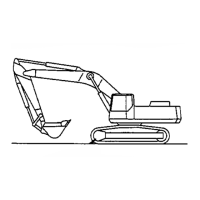

Pull out dipstick (G) and check that the oil level is between

the (H) and (L) marks on the dipstick.

5.

If the oil does not reach the (L) mark on dipstick (G), add

oil through the hole for the dipstick.

When adding oil, remove air bleeding plug (1).

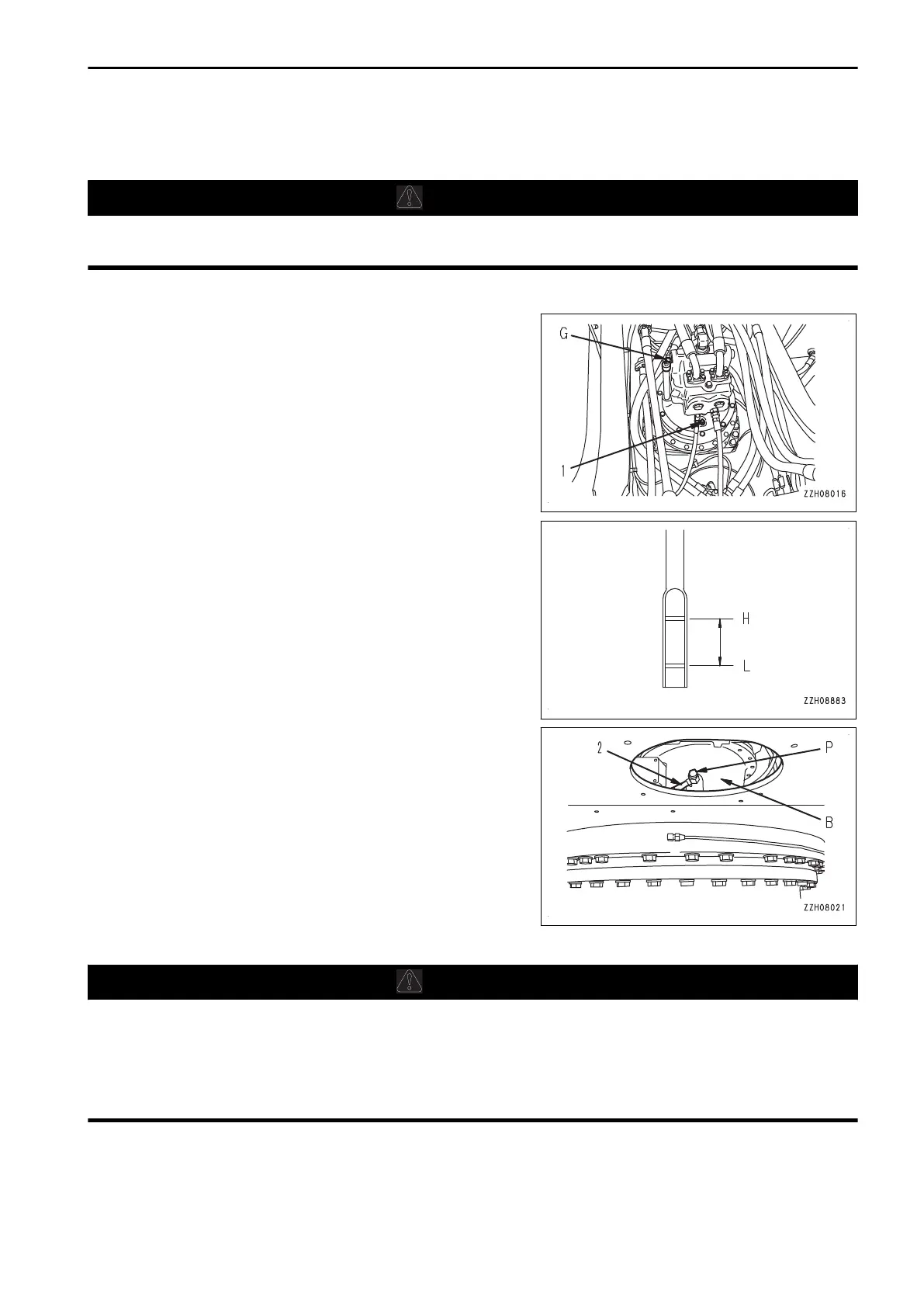

6.

If the oil level is above line (H) of dipstick (G), loosen drain

valve (P) to drain the excessive oil.

When draining the oil, take hose (2) out of inspection hole

(B) and place an oil container under hose (2), then “open”

the drain valve.

7.

After checking oil level or adding oil, insert dipstick (G) into

the hole and install air bleeding plug (1).

METHOD FOR CHECKING OIL LEVEL IN FINAL DRIVE CASE, ADDING OIL

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Accordingly, wait until they have cooled down before starting the work.

• If there is remaining pressure inside the case, the oil or plug may jump out. Loosen the plug slowly

to release the pressure.

• Do not stand in front of the plug when you loosen the plug.

Items to be prepared

Sliding T-handle (with 1/2" square drive).

MAINTENANCE MAINTENANCE PROCEDURE

4-57

Loading...

Loading...