EVERY 2000 HOURS MAINTENANCE

Maintenance for every 50, 250, 500 and 1000 hours service should be performed at the same time.

METHOD FOR CHANGING OIL IN FINAL DRIVE CASE

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Accordingly, wait until they have cooled down before starting the work.

• If there is remaining pressure inside the case, the oil or plug may jump out. Loosen the plug slowly

to release the pressure.

• Do not stand in front of the plug when you loosen the plug.

Refill capacity (each of right and left): 11 ℓ

Items to be prepared

• Container to receive drained oil

• A sliding T-handle (with 1/2" square drive).

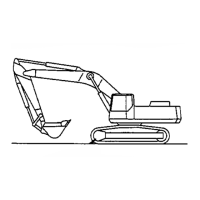

1.

Set the TOP mark at the top with the line running on TOP

mark and plug (P) perpendicular to the ground surface.

2.

Place the oil container to receive oil under plug (P).

3.

Remove plugs (P) and (F) by using the handle, and drain

oil.

Check O-rings attached to the plugs for damage. If neces-

sary, replace them with new ones.

4.

Tighten plug (P).

5.

Refill oil through plug (F) hole.

Plug (F) is installed at 2 places. Add oil through the one

with which it is easier to add oil and through which no in-

ternal gears are seen.

6.

When oil begins to overflow from the plug (F) hole, install

plug (F).

Tightening torque of plugs (P) and (F): 68.6 ± 9.8 Nm {7 ±

1 kgm}

METHOD FOR CLEANING HYDRAULIC TANK STRAINER

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury. Accordingly, wait until they have cooled down before starting the work.

• When removing the oil filler cap, the oil may spout out. Turn it slowly to release the internal pres-

sure, then remove it.

MAINTENANCE MAINTENANCE PROCEDURE

4-65

Loading...

Loading...