G-11

GL6000, GL7000, GL9000, GL11000, WSM

G GENERAL

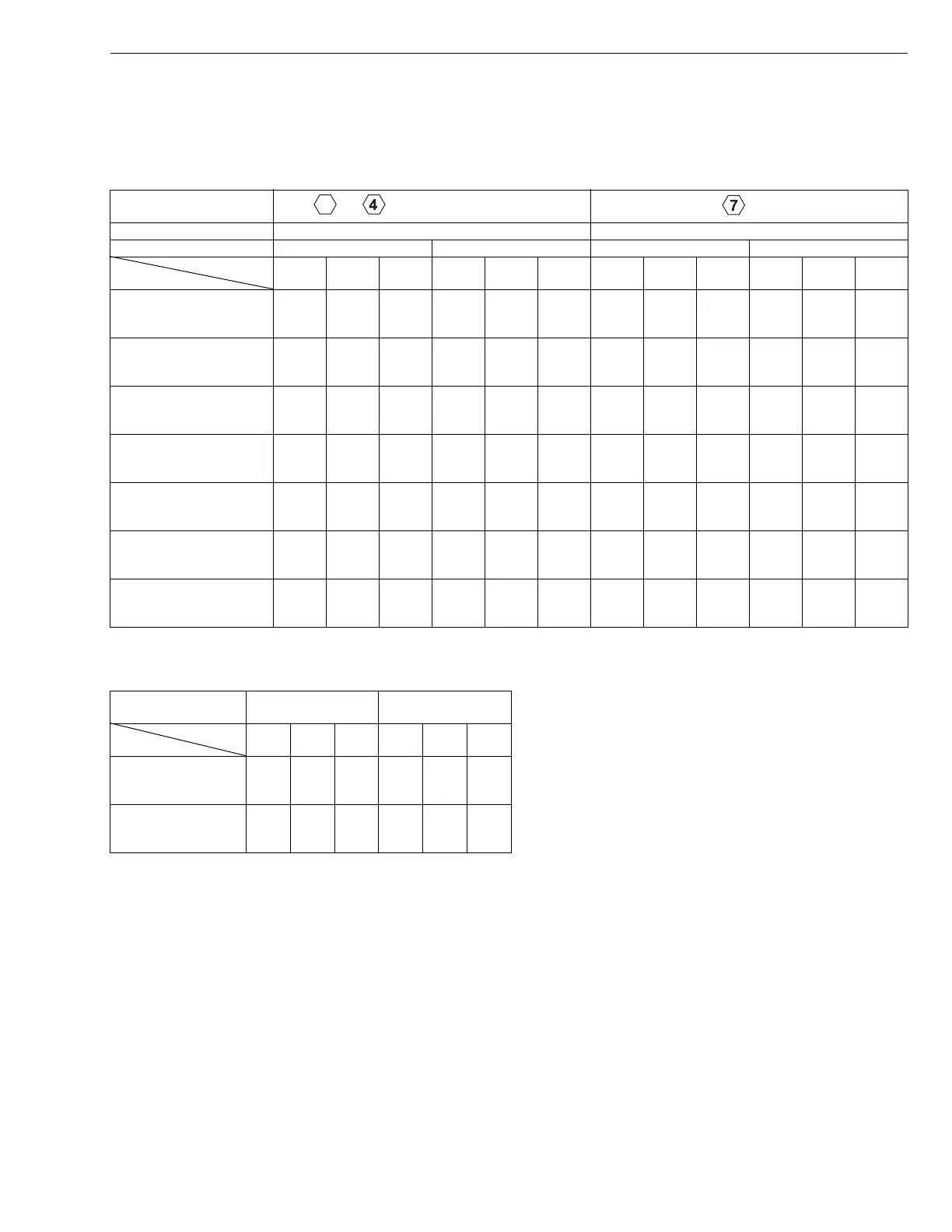

5. TIGHTENING TORQUES

[1] GENERAL USE SCREWS, BOLT AND NUTS

Screws, bolt and nuts whose tightening torque are not specified in this Workshop Manual should be tightened

according to the table below.

W1034542

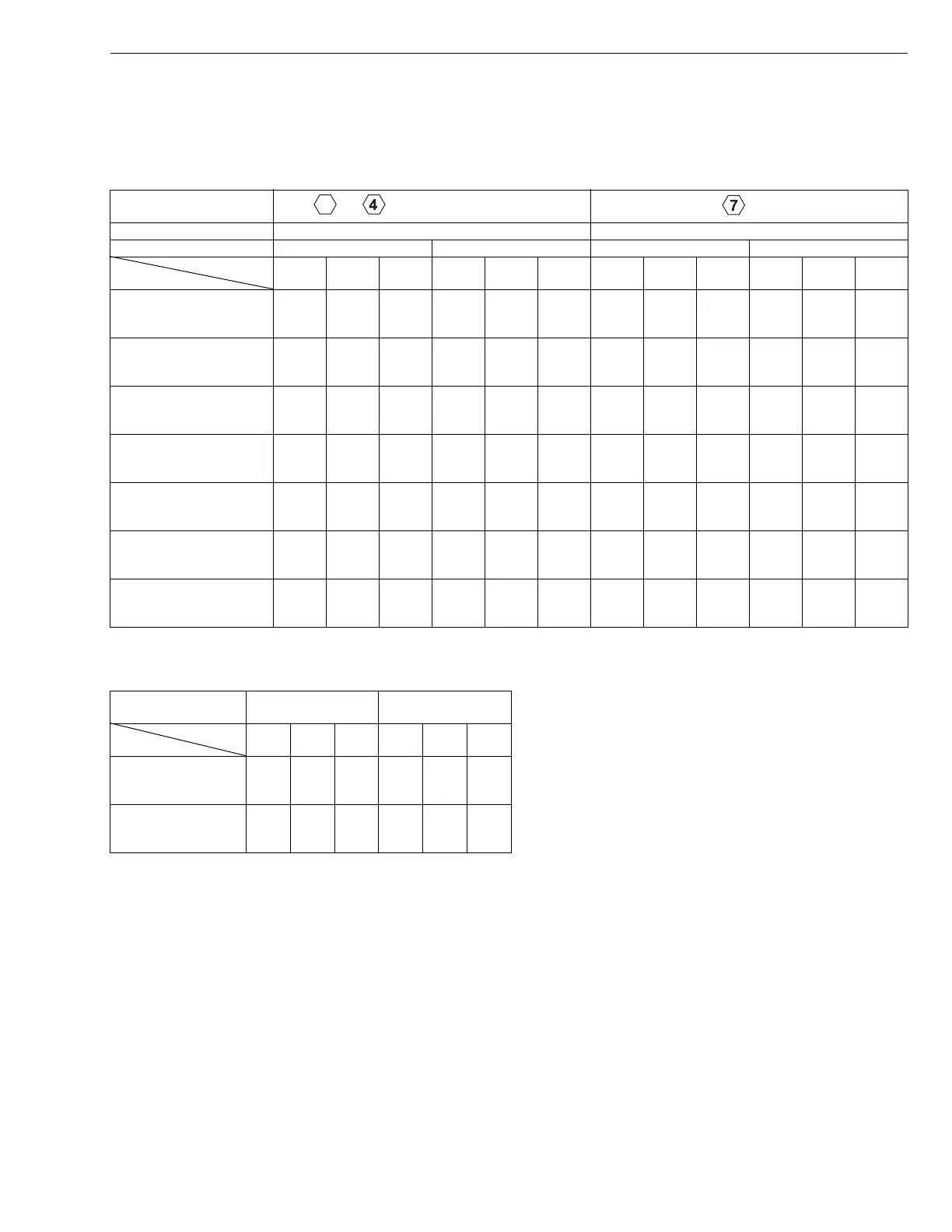

[2] STUD BOLTS

W1048139

Indication on top of

bolt

No-grade or 4T 7T

Material of bolt SS400, S20C S43C, S48C

Material of opponent part Ordinariness Aluminum Ordinariness Aluminum

Unit

Diameter

N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M4

(4 mm, 0.16 in.)

1.00

to

2.90

0.10

to

0.30

0.70

to

2.10

---------

M5

(5 mm, 0.20 in.)

1.90

to

3.60

0.20

to

0.40

1.40

to

2.70

---------

M6

(6 mm, 0.24 in.)

7.85

to

9.31

0.80

to

0.95

5.79

to

6.87

7.85

to

8.82

0.80

to

0.90

5.79

to

6.50

9.81

to

11.2

1.00

to

1.15

7.24

to

8.31

7.85

to

8.82

0.80

to

0.90

5.79

to

6.50

M8

(8 mm, 0.31 in.)

17.7

to

20.5

1.8

to

2.1

13.1

to

15.1

16.7

to

19.6

1.7

to

2.0

12.3

to

14.4

23.6

to

27.4

2.4

to

2.8

17.4

to

20.2

17

.7

to

20

.5

1.8

to

2.1

13.1

to

15.1

M10

(10 mm, 0.39 in.)

39.3

to

45.1

4.0

to

4.6

29.0

to

33.2

31.4

to

34.3

3.2

to

3.5

23.2

to

25.3

48.1

to

55.8

4.9

to

5.7

35.5

to

41.2

39.3

to

44.1

4.0

to

4.5

29.0

to

32.5

M12

(12 mm, 0.47 in.)

62.8

to

72.5

6.4

to

7.4

46.3

to

53.5

–––

77.5

to

90.2

7.9

to

9.2

57.2

to

66.5

62.8

to

72.5

6.4

to

7.4

46.3

to

53.5

M14

(14 mm, 0.55 in.)

108

to

125

11.0

to

12.8

79.6

to

92.5

–––

124

to

147

12.6

to

15.0

91.2

to

108

–––

Material of opponent

part

O

rdin

ariness Aluminum

Unit

Diameter

N·m kgf·m lbf·ft N·m kgf·m lbf·ft

M8

(8 mm, 0.31 in.)

11.8

to

15.6

1.2

to

1.6

8.68

to

11.5

8.82

to

11.8

0.90

to

1.2

6.51

to

8.67

M10

(10 mm, 0.39 in.)

24.6

to

31.3

2.5

to

3.2

18.1

to

23.1

19.7

to

25.4

2.0

to

2.6

14.5

to

18.8

Loading...

Loading...