SHOP MANUAL

Paragraph 61

Bulb

Fig. 71—To check reguiator cut-in voltage, con-

nect voltmeter to N terminal as shown and in-

staii a 30W bulb in place of 10A fuse.

minal and ground (Fig. 71). Remove lOA

fuse (connecting red wires) from fuse

panel and connect a 30W bulb in its

place. Start engine and increase speed

until charge indicator lamp goes off or

dims.

At this point, voltage reading

should be 4.5-5.8 volts. If cut-in voltage

is too high, bend voltage relay adjusting

arm (4-Fig. 72) closer to coil. If cut-in

voltage is low, bend adjusting arm away

from coil.

To check no-load regulating voltage,

connect voltmeter across B terminal and

ground (Fig. 73). Start engine and

operate above 1300 rpm, then discon-

nect battery ground cable. Increase

engine speed to obtain maximum

Fig. 72—Cut in voitage can be adjusted by

bend-

ing voitage relay adjusting arm (4). Bend voltage

regulator adjusting arm (2) to adjust regulated

voltage.

1,

Voltage regulator

2.

Adjusting

arm

;i.

Voltage relay

4,

Aiijustin^^ arm

22

3

1

12

14

16

20

21

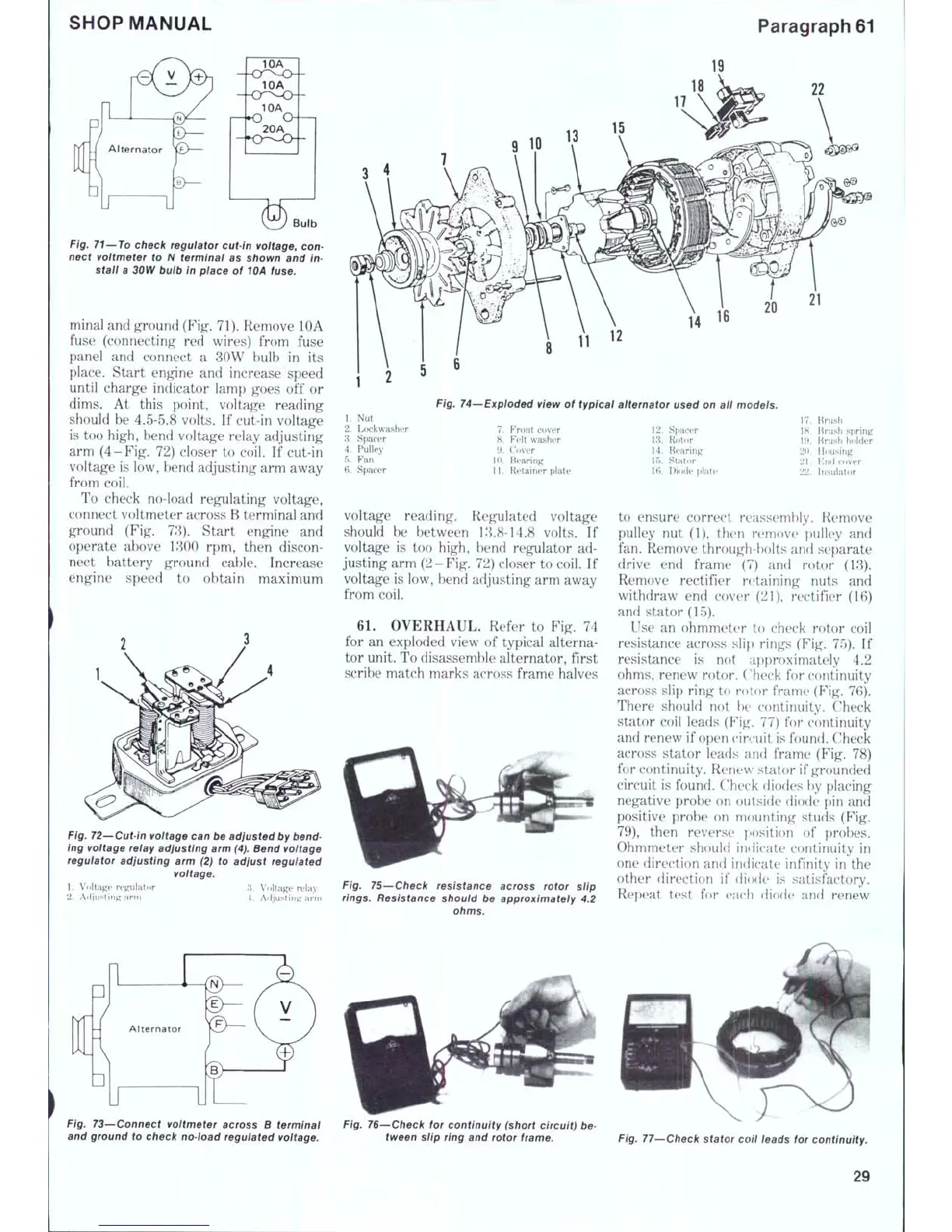

Fig. 74—Exploded view of typicai alternator used on aii models.

1.

Nut

2.

Lockwasher

3.

Spacer

4.

Pulley

5.

Fan '

6. Spacer

voltage reading. Regulated voltage

should be between 13.8-14.8 volts. If

voltage is too high, bend regulator ad-

justing arm (2-Fig. 72) closer to coil. If

voltage is low, bend adjusting arm away

from coil.

61.

OVERHAUL. Refer to Fig. 74

for an exploded view of typical alterna-

tor unit. To disassemble alternator, first

scribe match marks across frame halves

7.

Front cover

8. Felt washer

9. Cover

10.

Bearing

11.

Retainer plate

12.

Spacer

13.

Rotor

14.

Bearing

15.

Stator

16.

Diode plate

17.

Brush

18.

Brush spring

19.

Brush holder

20.

Housing

21.

Knd cover

22.

Insulator

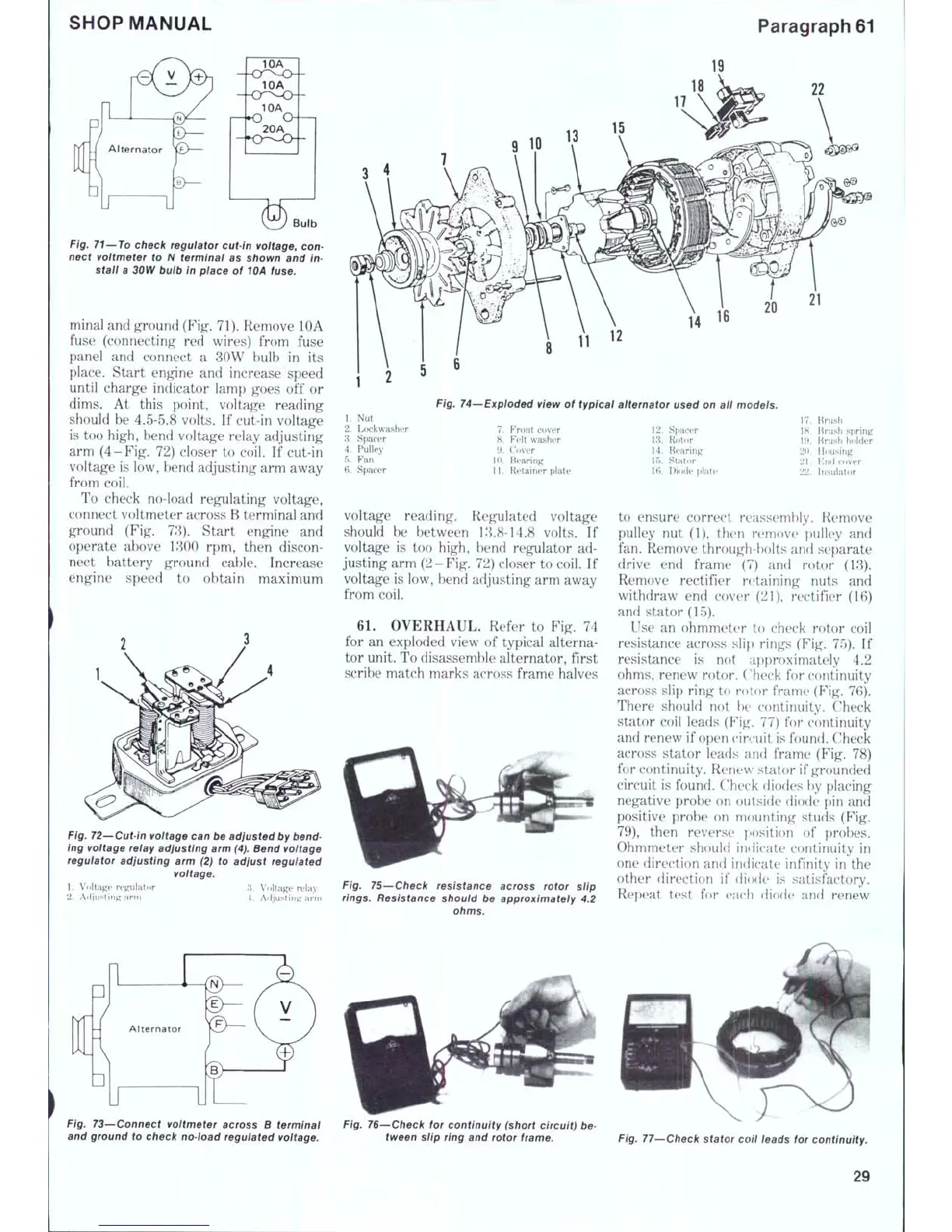

Fig. 75—Check resistance across rotor siip

rings. Resistance shouid be approximately 4.2

ohms.

to ensure correct reassembly. Remove

pulley nut (1), then remove pulley and

fan. Remove through-bolts and separate

drive end frame (7) and rotor (13).

Remove rectifier retaining nuts and

withdraw end cover (21), rectifier (16)

and stator (15).

Use an ohmmeter to check rotor coil

resistance across slip rings (Fig. 75). If

resistance is not af)proximately 4.2

ohms,

renew rotor. Check for continuity

across slip ring to rotor frame (Fig. 76).

There should not be continuity. Check

stator coil leads (F'i^. 77) for continuity

and renew if open circuit is found. Check

across stator leads and frame (Fig. 78)

for continuity. Renew stator if grounded

circuit is found. Check diodes hy placing

negative probe on outside diode pin and

positive probe on mounting studs (Fig.

79),

then reverse position of probes.

Ohmmeter should indicate continuity in

one direction and indicate infinity in the

other direction if diode is satisfactory.

Repeat test for each diode and renew

Fig. 73—Connect voltmeter across B terminai Fig. 76—Check for continuity (short circuit) be-

and ground to check no-ioad regulated voitage. tween siip ring and rotor frame. Fig. 77—Check stator coii leads for continuity.

29

Loading...

Loading...