Page 11

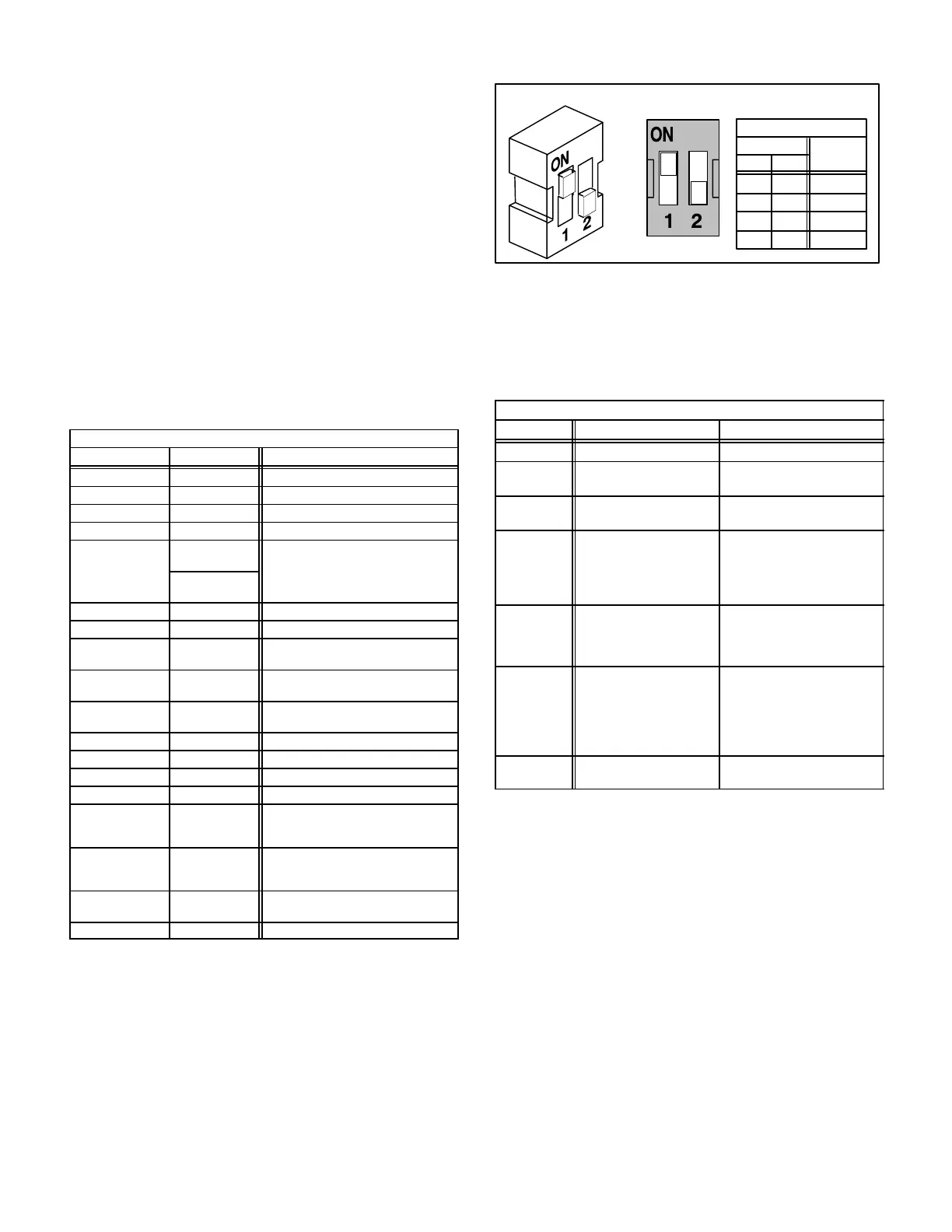

Fan OFF" timings (time that the blower operates after a

heating or cooling demand has been satisfied) are de-

termined by the arrangement of switches on the furnace

control board. See figure 5. To adjust fan off " timings,

gently reposition the switches to a new timing position.

Figure 6 shows the various fan off" timings and how

switches should be positioned. 80MGF−1, −2, −3, −4 and −6

units are shipped with a factory fan off" setting of 180 sec-

onds. 80MGF−5 and −7 units are shipped with factory "off"

setting of 60 seconds. Fan off" time will affect comfort and

efficiency and is adjustable to satisfy individual applica-

tions. The fan off" timing is initiated after a heating or cool-

ing demand but not after a blower demand (that is, when

indoor thermostat switch is changed from ON to AUTO

and heating/cooling demand is not present, the blower

stops immediately).

TABLE 2

FURNACE CONTROL A3 TERMINAL DESIGNATIONS

Terminal Type Function

Y Screw Strip Cooling Demand

G Screw Strip Blower Demand

R Screw Strip 24VAC to Thermostat

W Screw Strip Heating Demand

Early Units

1/4" Spade

Later Units

Screw Strip

ommon

120VAC HOT 1/4" Spade Line Voltage In

AUX 1/4" Spade Line Voltage Out (Switched)

CMB BLWR 1/4" Spade

Switched 120VAC to

Combustion Air Blower

ACB HEAT 1/4" Spade

Switched 120VAC to

Blower Heating Tap

ACB COOL 1/4" Spade

Switched 120VAC to Blower

Cooling Tap

VALVE 1/4" Spade 24VAC to Gas Valve

24VAC HOT 1/4" Spade 24VAC In From Transformer

GROUND 1/4" Spade To Cabinet Ground

FLAME SENSE 1/4" Spade Flame Microamp Sensing

PSW 1/4" Spade

24VAC In From Pressure Switch

Switch Open: Prohibits Ignition

Switch Closed: Allows Ignition

HI LIMIT IN 1/4" Spade

24VAC In From Limits

Limit Open: Closes Gas Valve

Limits Closed: Allows Ignition

HI LIMIT OUT 1/4" Spade

24VAC to Limit Train

and Pressure Switch

ROLLOUT IN 1/4" Spade 24VAC In From Rollout Switches

FIGURE 6

FAN-OFF TIME ADJUSTMENT SWITCHES

LOCATED ON FURNACE CONTROL (A3)

Fan-Off Timings

Switch

12

Timing

Seconds

Off

OnOff

Off

OffOn

On On

120

90

180

240

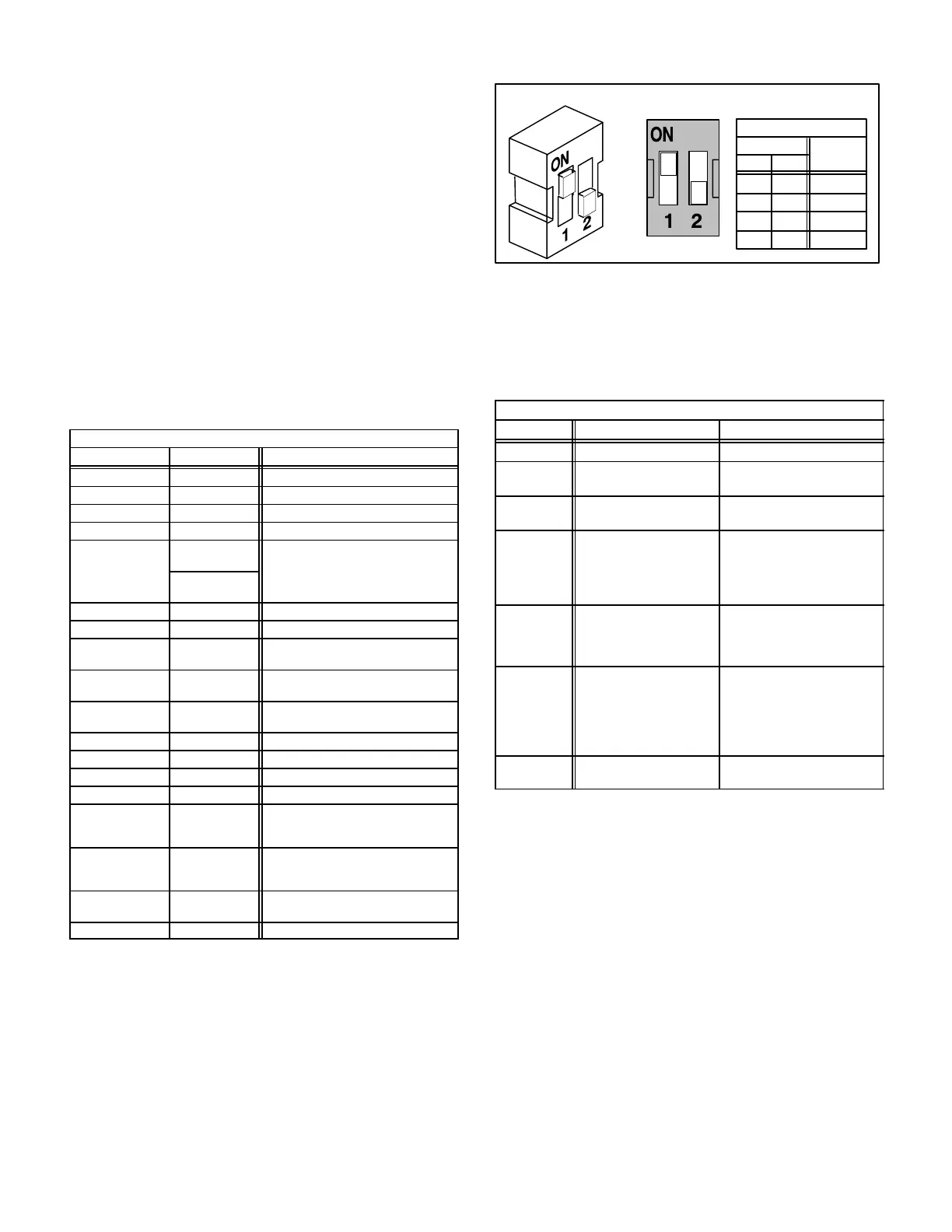

Diagnostic LED

The furnace control is equipped with a diagnostic LED

used for troubleshooting the unit and the control. LED

functions are shown in table 3.

TABLE 3

Furnace Control A3 Diagnostic LED

LED State Meaning Remedy

Steady On Control Failure Replace Control

Slow Flash

Normal Operation and

No Call For Heat

- - - -

Fast Flash

Normal Operation with

Call For Heat

- - - -

Two

Flashes

Control Lockout

Failed to Sense or Sustain

Flame. Check Gas Valve,

Burners, Spark Electrode

and Wire, Flame Sensor.

Replace Control If All OK.

Three

Flashes

Pressure Switch Open

Failed to Prove Combus-

tion Blower Operation or

Blocked Vent. Repair or

Replace as Necessary.

Four

Flashes

Open Limit

Check Primary Limit, Rollout

Switches and Secondary

Limits. Find source of Over-

temperature. If all OK, Reset

or Replace Limits as Neces-

sary.

Five

Flashes

Flame Sensed and Gas

Valve Not Energized.

Check Gas Valve. If OK,

Check Flame Sensor.

Loading...

Loading...