Page 50

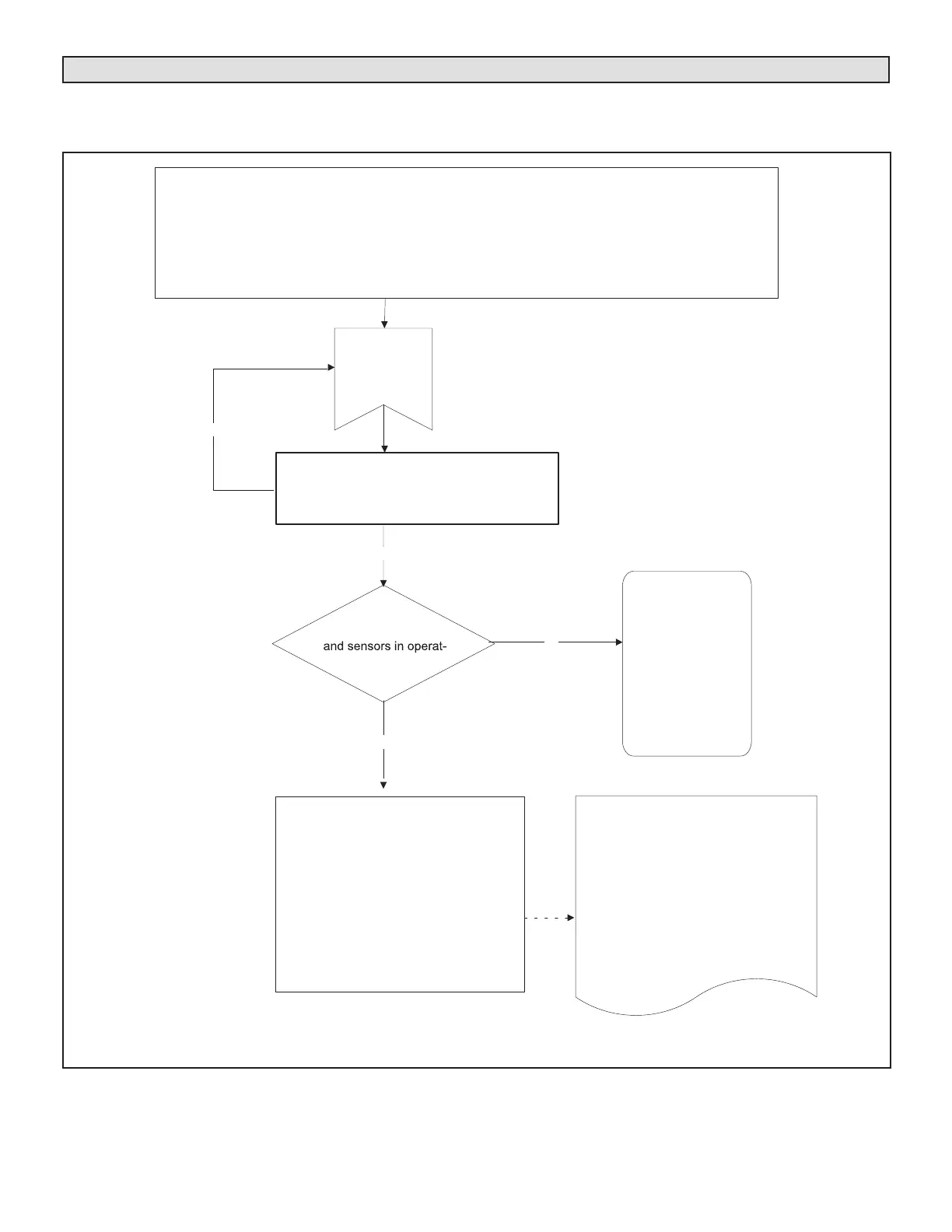

Unit Sequence of Operation

The following gures illustrate the overall unit sequence of operation along with the operation of various pressure switches

and temperature sensors. The gures also illustrate the use of the compressor anti-short-cycle function in relation to unit

Status, unit Fault and lockout LED Codes and unit system operation interactions.

Yes

No

Yes

No

Room thermostat provides a Y1 or Y2 demand to

the main control on systems with a conventional

24VAC thermostat or a percentage of demand on

systems with an S30/S40 thermostat.

All switches closed

ing range.

Check for status or

fault codes in the

outdoor control or

room thermostat.

(NOTE - Refer to low

pressure and high

pressure switch flow

charts for sequence

of operation.

1. View the AIR CONDITIONING screen

for current compressor frequency in

hertz.

2. View the AIR HANDLER screen for

actual CFM of the indoor blower

motor.

From idle mode

Outdoor Control

1. Sends a demand to the compressor

inverter to start and run the

compressor up to the requested

pumping capacity (Frequency in

hertz).

2.

Output signal is provided on PWM

and COM terminals to start and run the

ECM outdoor fan at the demand RPM.

3. Sends a communication signal into

the indoor unit to start and run the

supply fan motor at the demand air

volume (CFM).

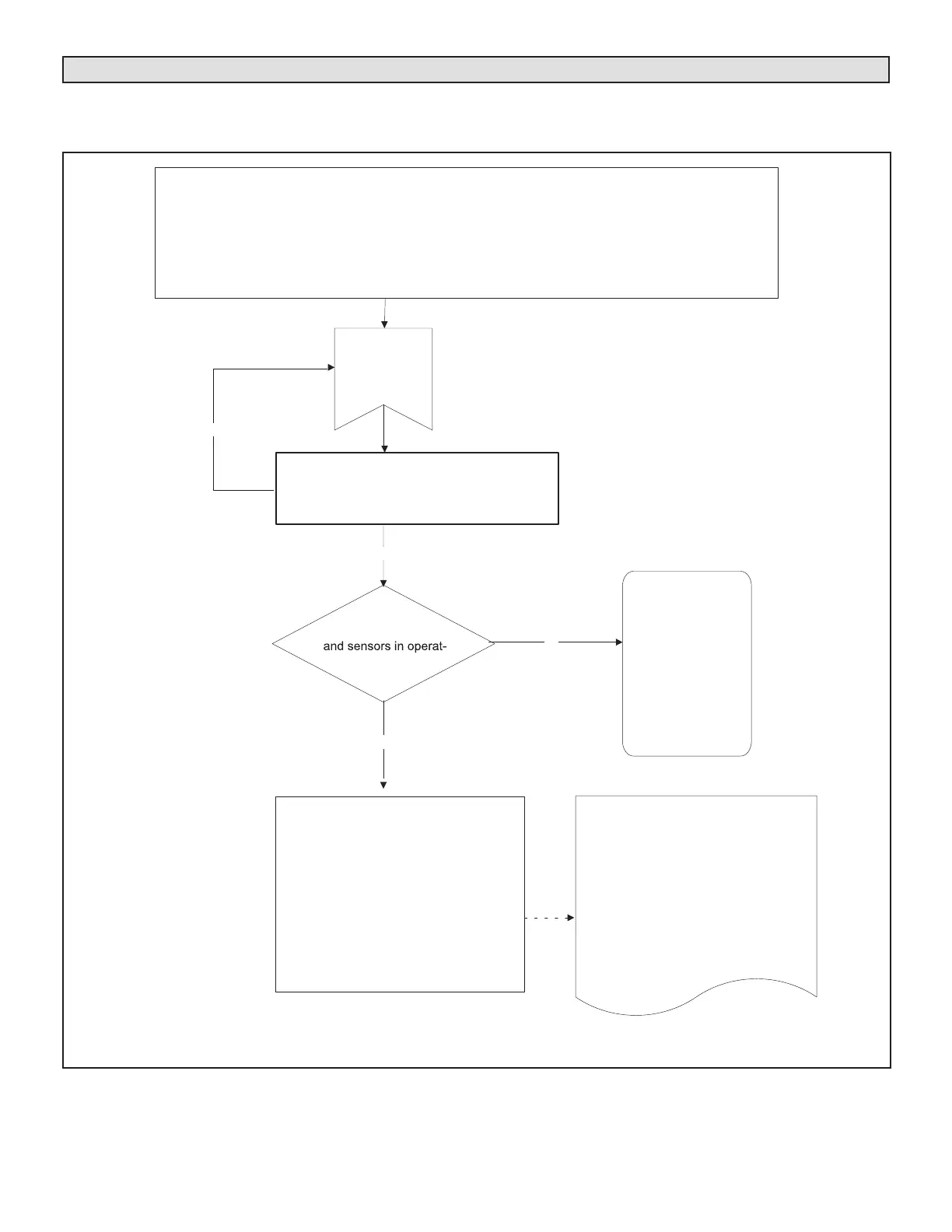

On 24 VAC power-up or outdoor reset, the outdoor control shall perform the following tasks:

1. Start the anti-short cycle 3-minute delay in the outdoor control.

2. Check status of the temperature sensor and pressure devices.

3. If the outdoor control does not detect any error codes, outdoor control sends 24 volts out on the

CNTCTR terminals to pull in the contactor coil. (Note - These checks take about 60 seconds.)

4. The contactor contacts pull IN and main power is applied to the compressor inverter.

Diagnostic Screen

FIGURE 22. 24 Volt Power-Up or Outdoor Reset

Loading...

Loading...