Page 65

ERROR:

TABLE 14. Outdoor Control 7-Segment Display Alert Codes - Top Cap Switch

NOTE - System fault and lockout codes take precedence over system status codes (cooling, heating operating percentages or de-

frost/dehumidication). Only the latest active fault or lockout codes are displayed (if present). If no fault or lockout codes are active,

then system status codes are displayed. Alert codes are also displayed on the communicating thermostat.

Alert

Codes

Priority Alarm Description Possible Causes and Clearing Alarm

E 422 Moderate

Compressor top cap switch

exceeding thermal limit.

The top of the compressor is hot. Refrigerant charge may be low, or low mass ow

of refrigerant. Check TXV, clogged lter drier, condenser fan motor, indoor blower

motor, conrm indoor coil is clean. Check to make sure the blue wires from the

top thermostat did not get pulled o one of the TP terminal on the outdoor control

board.

E 442 Critical

The top cap switch has opened 5

times within one hour. As a result,

the outdoor unit is locked out.

When compressor thermal protection sensor opens 5 times within 1 hour, outdoor

stops working.

To clear, disconnect power to the indoor unit (24VAC power source to the outdoor

control) which will power o the outdoor control and will open the outdoor unit

contactor, which interrupts power to the inverter and then re-apply power.

Reactor Operations, Checkout and Status / Error Codes

OPERATION:

Reactor (Inductor or choke) is a passive two-terminal electrical component that stores energy in its magnetic eld. Reac-

tors are one of the basic components used in electronics where current and voltage change with time, due to the ability of

inductors to delay and reshape alternating currents.

CHECKOUT:

Main Power ON – Voltage IN reactor should be the same as the voltage OUT. With main power OFF and reactor discon-

nected from system; resistance between leads should be the same

STATUS CODES:

None

ERROR CODES:

None

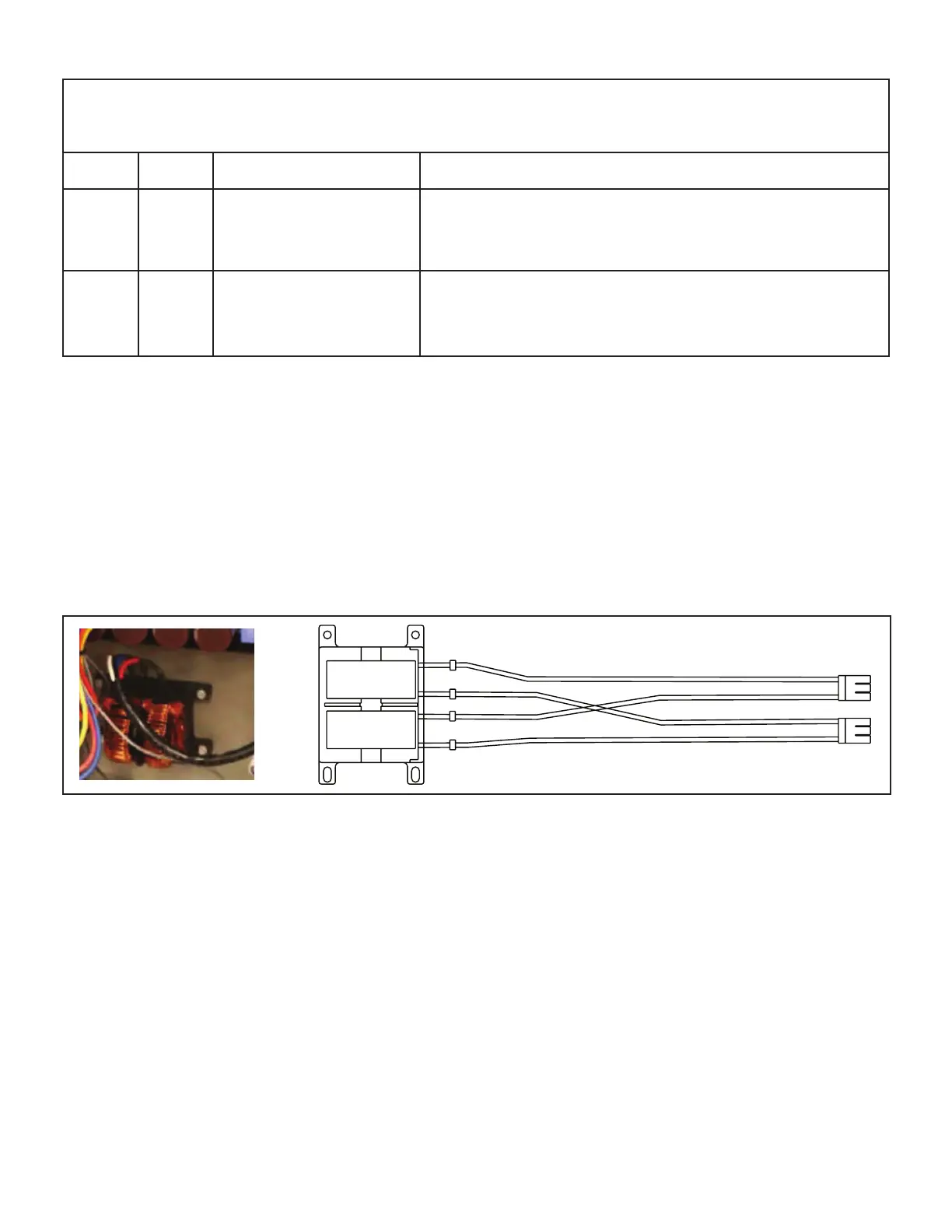

VOLTAGE “IN”

VOLTAGE “OUT”

FIGURE 41. EL23XCVS/E18XCV Reactor

Outdoor Fan Operation and Checkout

OPERATION:

EL23XCV units have a variable speed ECM fan motor. The variable speed ECM fan motor is controlled by PWM fan output

when the compressor is running and will vary the fan speed to match the compressor capacity.

LOW AMBIENT OPERATION:

The EL23XCV units have factory installed low ambient operator that will control the condenser fan motor based upon liquid

line temperature.

EL23XCV units have a variable speed ECM fan motor. The outdoor control will begin to modulate the outdoor fan motor

speed is below 65°F to maintain a liquid line sensor temperature between 58°F and 70°F. If the liquid line sensor drops

below 55°F the control will cycle the fan o until liquid temperature rises above 58°F.

Loading...

Loading...