Page 52

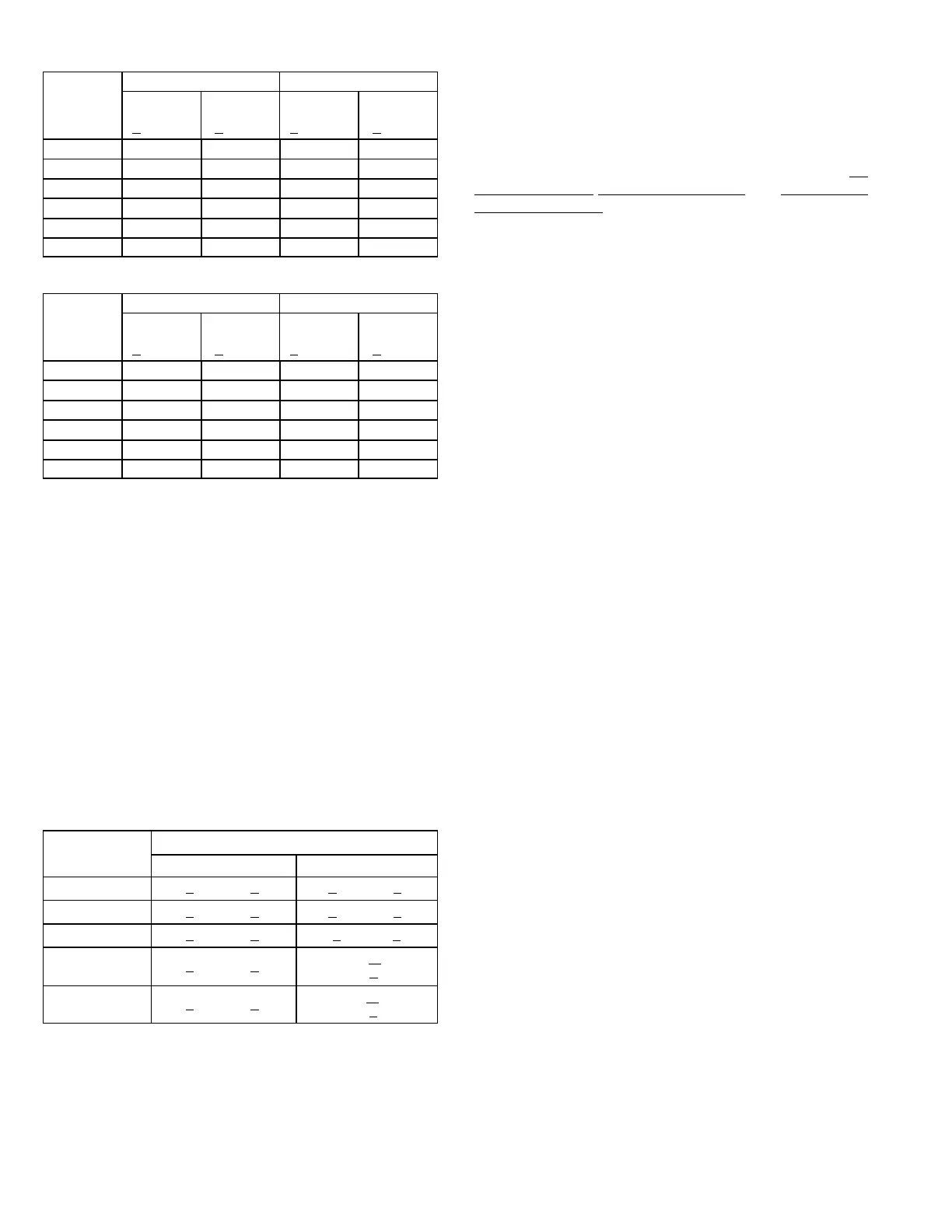

TABLE 15

LGH/LCH150S Fin/Tube Coil - TXV

Outdoor

Coil

Entering

Air Temp

CIRCUIT 1 CIRCUIT 2

Dis

charge

+

10 psig

Suction

+

5 psig

Dis

charge

+

10 psig

Suction

+

5 psig

655 F 275 140 298 139

755 F 312 142 335 141

855 F 354 143 374 142

955 F 398 146 419 146

1055 F 449 149 465 148

1155 F 500 151 514 150

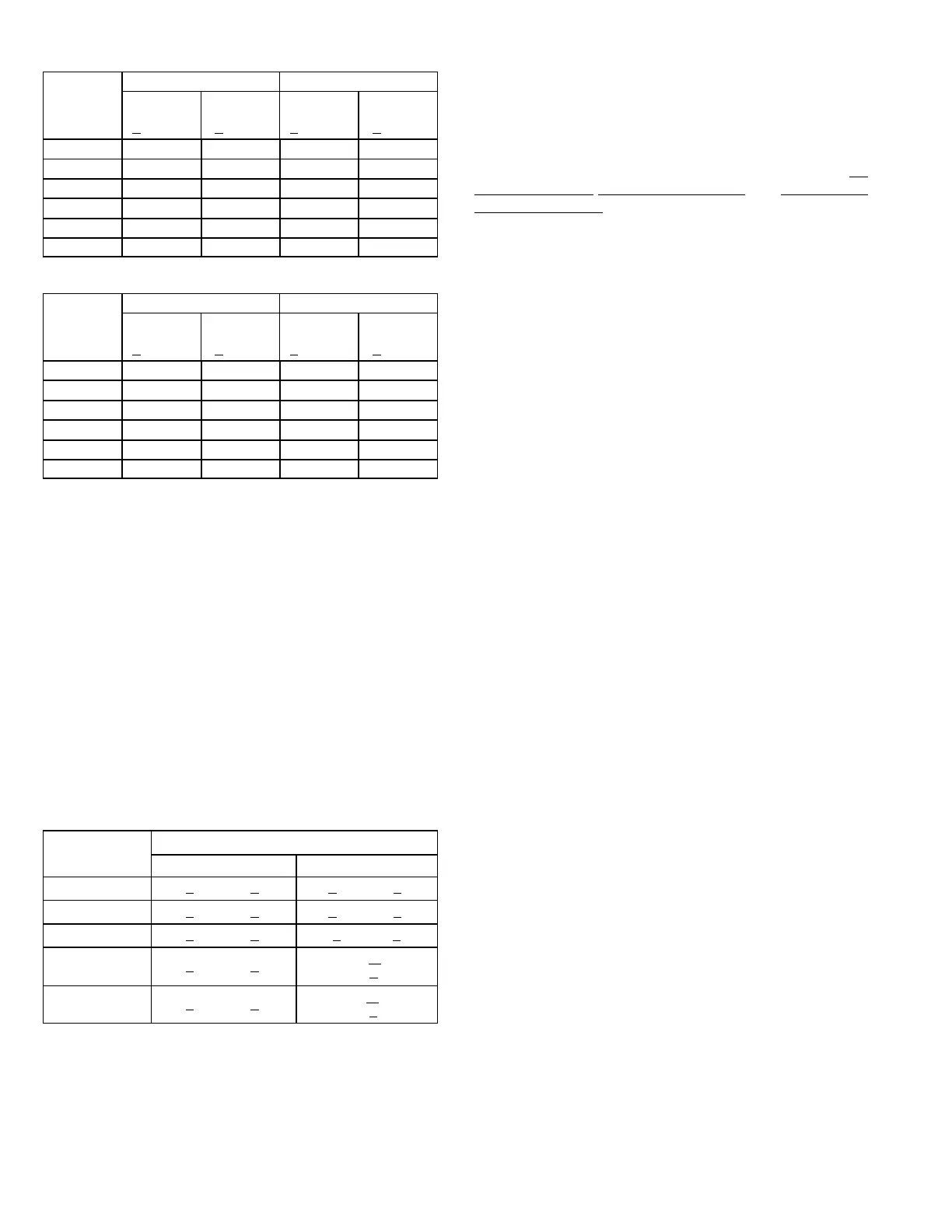

TABLE 16

LGH/LCH150S Fin/Tube Coil Hot Gas Reheat - TXV

Outdoor

Coil

Entering

Air Temp

CIRCUIT 1 CIRCUIT 2

Dis

charge

+

10 psig

Suction

+

5 psig

Dis

charge

+

10 psig

Suction

+

5 psig

655 F 280 136 296 136

755 F 319 141 335 141

855 F 360 142 376 143

955 F 407 144 420 144

1055 F 455 147 466 147

1155 F 510 150 518 150

Charge Verification - Approach Method - AHRI Testing

(Fin/Tube Coil Continued)

1- Using the same thermometer, compare liquid tempera

ture to outdoor ambient temperature.

Approach Temperature = Liquid temperature (at con

denser outlet) minus ambient temperature.

2- Approach temperature should match values in table 17.

An approach temperature greater than value shown indi

cates an undercharge. An approach temperature less

than value shown indicates an overcharge.

3- The approach method is not valid for grossly over or

undercharged systems. Use tables 9 through 16 as a

guide for typical operating pressures.

TABLE 17

APPROACH TEMPERATURE - FIN/TUBE COIL - TXV

Unit

Liquid Temp. Minus Ambient Temp.

1st Stage 2nd Stage

092

6°F + 1 (3.3°C + 0.5) 7°F + 1 (3.9°C + 0.5)

102

6°F + 1 (3.3°C + 0.5) 9°F + 1 (5.0°C + 0.5)

120 & 150

6°F + 1 (3.3°C + 0.5) 10°F+1 (5.6°C + 0.5)

092, 120 & 150

Hot Gas Reheat

6°F + 1 (3.3°C + 0.5)

8°F + 1

(4.4°C +

0.5)

102

Hot Gas Reheat

6°F + 1 (3.3°C + 0.5)

9°F + 1

(5.0°C +

0.5)

F-Refrigerant Charge and Check - Fin/Tube Coil & RFC

LGH/LCH150S

WARNING-Do not exceed nameplate charge under any

condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant, re

claim the charge, evacuate the system, and add required

nameplate charge.

NOTE - System charging is not recommended below 60_F

(15_C). In temperatures below 60_F (15_C), the charge

must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Make sure outdoor coil is clean. Attach gauge manifolds

and operate unit at full CFM in cooling mode with econo

mizer disabled until system stabilizes (approximately five

minutes). Make sure all outdoor air dampers are closed.

2- Check each system separately with all stages operat

ing. Compare the normal operating pressures (see table

18) to the pressures obtained from the gauges. Check

unit components if there are significant differences.

3- Measure the outdoor ambient temperature and the suc

tion pressure. Refer to the appropriate circuit charging

curve to determine a target liquid temperature.

Note - Pressures are listed for sea level applications.

4- Use the same thermometer to accurately measure the

liquid temperature (in the outdoor section).

D If measured liquid temperature is higher than the

target liquid temperature, add refrigerant to the

system.

D If measured liquid temperature is lower than the

target liquid temperature, recover some refrigerant

from the system.

5- Add or remove charge in increments. Allow the system

to stabilize each time refrigerant is added or removed.

6- Continue the process until measured liquid tempera

ture agrees with the target liquid temperature. Do not

go below the target liquid temperature when adjusting

charge. Note that suction pressure can change as

charge is adjusted.

7- Example LGH/LCH150 Circuit 1: At 95°F outdoor am

bient and a measured suction pressure of 130psig, the

target liquid temperature is 96°F. For a measured liquid

temperature of 106°F, add charge in increments until

measured liquid temperature agrees with the target liq

uid temperature.

Loading...

Loading...