Page 57

V- SYSTEMS SERVICE CHECKS

A-Heating System Service Checks

All LGH units are ETL/CSA design certified without mod

ification.

Before checking piping, check with gas company or authori

ties having jurisdiction for local code requirements. Refer to

the LGH installation instruction for more information.

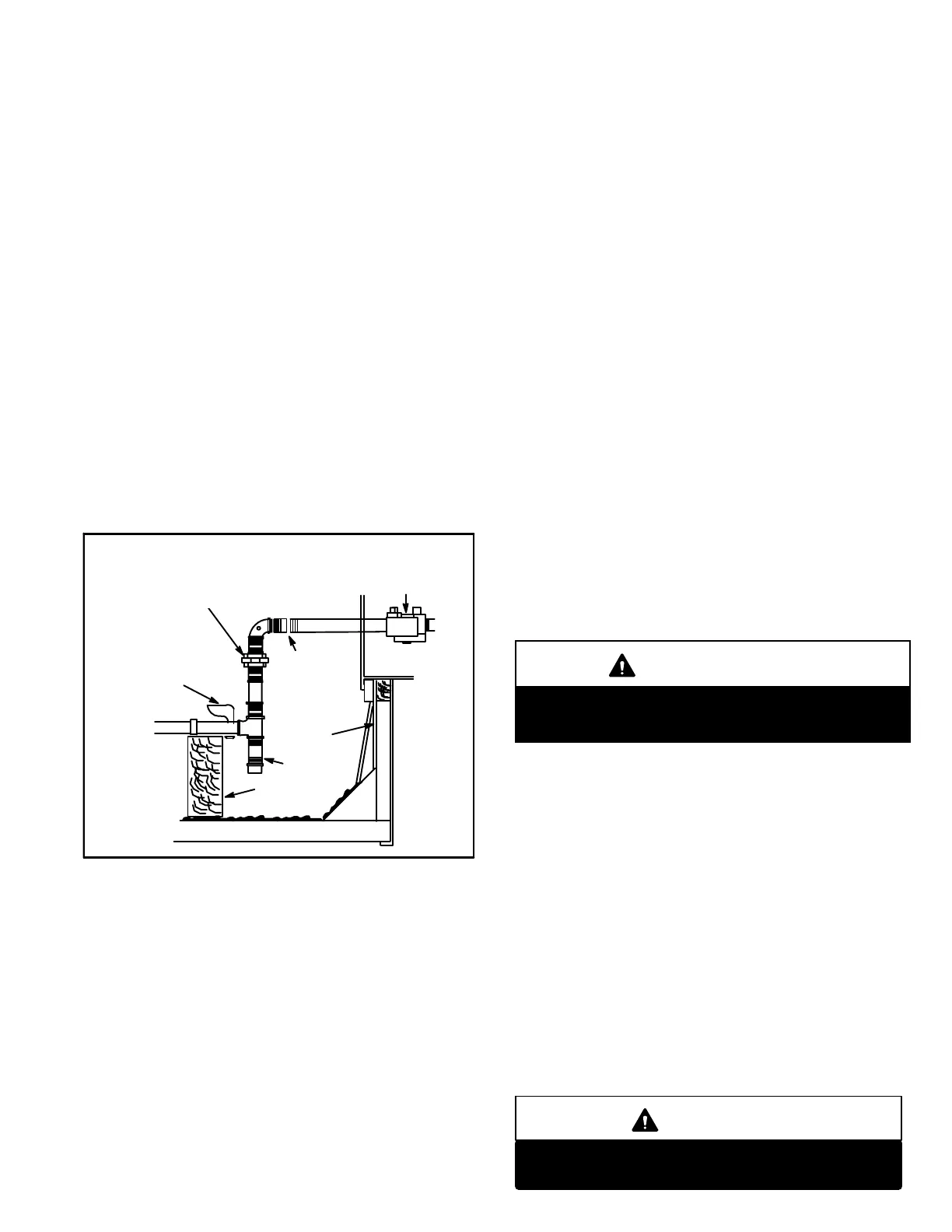

1-Gas Piping

Gas supply piping must not allow more than 0.5”W.C.

(124.3 Pa) drop in pressure between the gas meter and the

unit. Supply gas pipe must not be smaller than the unit gas

connection. Refer to installation instructions for details.

2-Testing Gas Piping

NOTE-In case emergency shutdown is required, turn off

the main manual shut‐off valve and disconnect the main

power to the unit. These controls should be properly la

beled by the installer.

When pressure testing gas lines, the gas valve must be dis

connected and isolated. Gas valves can be damaged if

subjected to more than 0.5 psig [14”W.C. (3481 Pa)]. See

figure 38.

UNIT

GROUND

JOINT UNION

MANUAL MAIN

SHUT-OFF VALVE

(REFER TO LOCAL CODES)

GAS PIPING

SUPPORT

DRIP LEG

ROOF

MOUNTING

FRAME

GAS PIPING COMPONENTS

REFER TO INSTALLATION INSTRUCTIONS

VALVE

CAP HERE TO

ISOLATE VALVE

WHEN PRESSURE

TESTING LINE

FIGURE 38

When checking piping connection for gas leaks, use the

preferred means. Common kitchen detergents can

cause harmful corrosion on various metals used in gas

piping. The use of specialty Gas Leak Detector is strong

ly recommended.

Do not use matches, candles, flame or any other source of

ignition to check for gas leaks.

3-Testing Gas Supply Pressure

When testing gas supply pressure, connect test gauge to the

inlet pressure tap located on unit gas valve GV1 and or

GV3. Test supply gas pressure with unit firing at maximum

rate (both stages energized). Make sure the reading falls

within the range of the following values. Low pressure may

result in erratic operation or “underfire.” High pressure can

result in permanent damage to the gas valve or “overfire.”

For natural gas units, operating pressure at the unit gas

connection must be between 4.7”W.C. and 10.5”W.C.

(1168 Pa and 2610 Pa). For L.P. gas units, operating

pressure at the unit gas connection must be between

10.8”W.C. and 13.5”W.C. (2685.3 Pa and 3356.7 Pa).

On multiple unit installations, each unit should be checked

separately while operating at maximum rate, beginning with

the one closest to the supply gas main and progressing to

the one furthest from the main. Multiple units should also

be tested with and without the other units operating.

Supply pressure must fall within the range listed in the

previous paragraph.

4-Check and Adjust Manifold Pressure

After line pressure has been checked and adjusted, check

manifold pressure. Move test gauge to the outlet pressure

tap located on unit gas valve GV1 and or GV3. See figure

37 for location of pressure tap on the gas valve.

The manifold pressure is factory set and should not require

adjustment. If manifold pressure is incorrect and no other

source of improper manifold pressure can be found, the

valve must be replaced. See figure 37 for location of gas

valve (manifold pressure) adjustment screw.

All gas valves are factory regulated. The gas valve should

completely and immediately cycle off in the event of gas or

power failure. The manual shut‐off knob can be used to im

mediately shut off gas supply.

CAUTION

For safety, connect a shut‐off valve between the ma

nometer and the gas tap to permit shut off of gas

pressure to the manometer.

Manifold Adjustment Procedure

1- Connect test gauge to the outlet pressure tap on the

gas valve. Start the unit (call for second stage heat)

and allow five minutes for the unit to reach steady

state.

2- While waiting for the unit to stabilize, notice the

flame. The flame should be stable without flashback

and should not lift from the burner heads. Natural

gas should burn basically blue with some clear

streaks. L.P. gas should burn mostly blue with some

clear yellow streaks.

3- After allowing the unit to stabilize for five minutes,

record the manifold pressure and compare to the val

ues given in table 4.

CAUTION

Disconnect heating demand as soon as an accu

rate reading has been obtained.

Loading...

Loading...