Page 54

G-Refrigerant Charge and Check - Fin/Tube Coil & TXV

LGH/LCH094U, 122U, 152U

WARNING-Do not exceed nameplate charge under any

condition.

This unit is factory charged and should require no further

adjustment. If the system requires additional refrigerant, re

claim the charge, evacuate the system, and add required

nameplate charge. This unit is equipped with solenoid valves

which do not allow refrigerant flow between the high side and

the low side when the unit is de-energized. When reclaiming/

evacuating the system, make sure refrigerant/vacuum is

pulled from both the suction and discharge lines. When adding

nameplate charge, add 1/3 to the suction line and 2/3 to the

discharge line.

NOTE - System charging is not recommended below 60°F

(15°C). In temperatures below 60°F (15°C) , the charge

must be weighed into the system.

If weighing facilities are not available, or to check the

charge, use the following procedure:

IMPORTANT - Charge unit in standard cooling mode.

1- Attach gauge manifolds and operate unit in cooling

mode with economizer disabled until system stabilizes

(approximately five minutes). Make sure outdoor air

dampers are closed.

2- Make sure both compressors are operating.

3- Use a thermometer to accurately measure the outdoor

ambient temperature.

4- Apply the outdoor temperature to tables 19 through 21

to determine normal operating pressures. Pressures

are listed for sea level applications at 80

5F dry bulb

and 67

5F wet bulb return air.

5- Compare the normal operating pressures to the pres

sures obtained from the gauges. Minor variations in

these pressures may be expected due to differences in

installations. Significant differences could mean that

the system is not properly charged or that a problem

exists with some component in the system. Correct

any system problems before proceeding.

6- If discharge pressure is high, remove refrigerant from

the system. If discharge pressure is low, add refrigerant

to the system.

S Add or remove charge in increments.

S Allow the system to stabilize each time refrigerant

is added or removed.

7- Use the following approach method along with the nor

mal operating pressures to confirm readings.

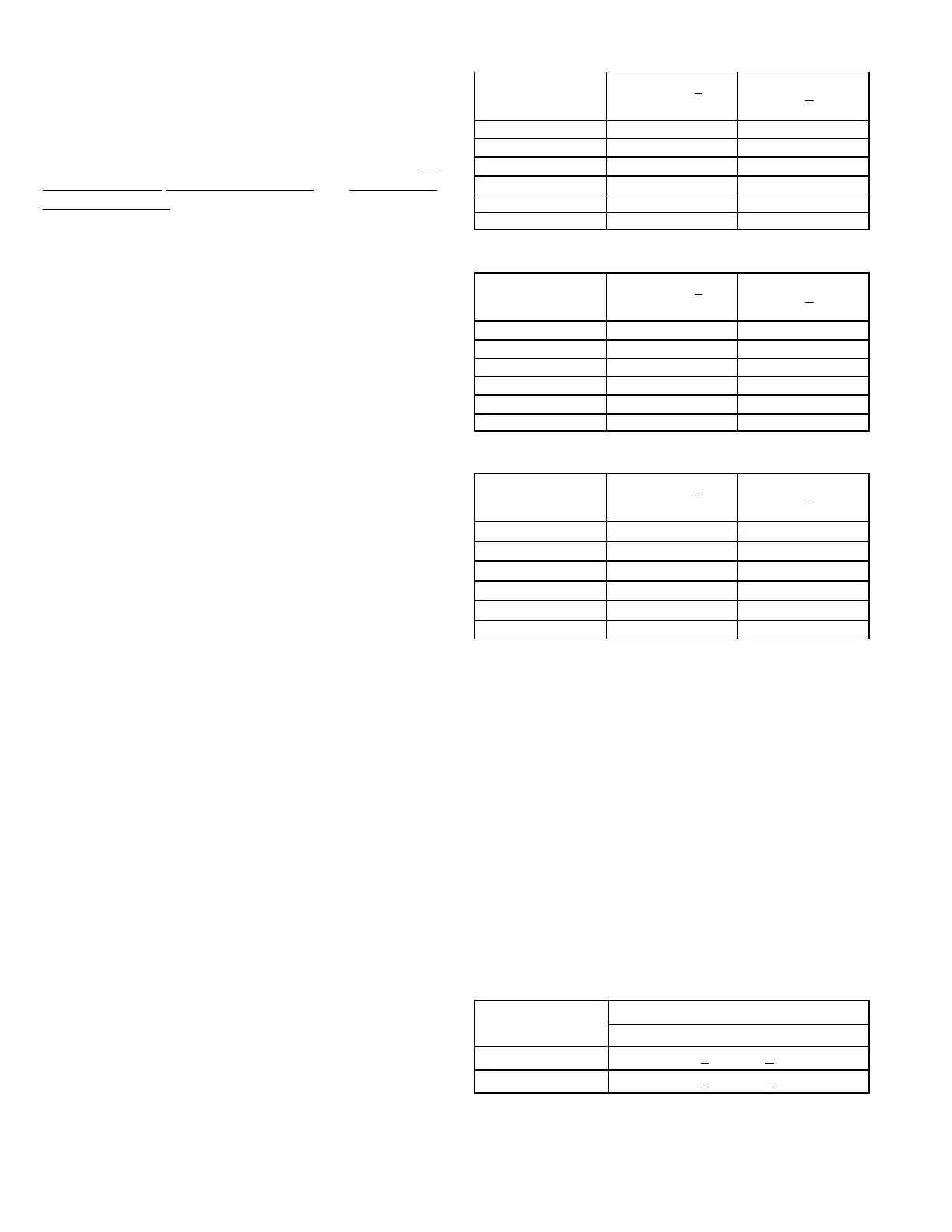

TABLE 19

LGH/LCH094U

Outdoor Coil

Entering Air

Temp

Discharge +10

psig

Suction +5 psig

655 F 238 136

755 F 273 141

855 F 313 143

955 F 361 146

1055 F 396 149

1155 F 448 152

TABLE 20

LGH/LCH122U

Outdoor Coil

Entering Air

Temp

Discharge +10

psig

Suction +5 psig

655 F 250 134

755 F 288 138

855 F 331 141

955 F 378 143

1055 F 412 144

1155 F 463 147

TABLE 21

LGH/LCH152U

Outdoor Coil

Entering Air

Temp

Discharge +10

psig

Suction +5 psig

655 F 266 129

755 F 305 132

855 F 346 134

955 F 391 138

1055 F 443 141

1155 F 498 143

Charge Verification - Approach Method - AHRI Testing

(Fin/Tube Coil Continued)

1- Using the same thermometer, compare liquid tempera

ture to outdoor ambient temperature.

Approach Temperature = Liquid temperature (at con

denser outlet) minus ambient temperature.

2- Approach temperature should match values in table

22. An approach temperature greater than value

shown indicates an undercharge. An approach tem

perature less than value shown indicates an over

charge.

3- The approach method is not valid for grossly over or

undercharged systems. Use tables19 through21 as a

guide for typical operating pressures.

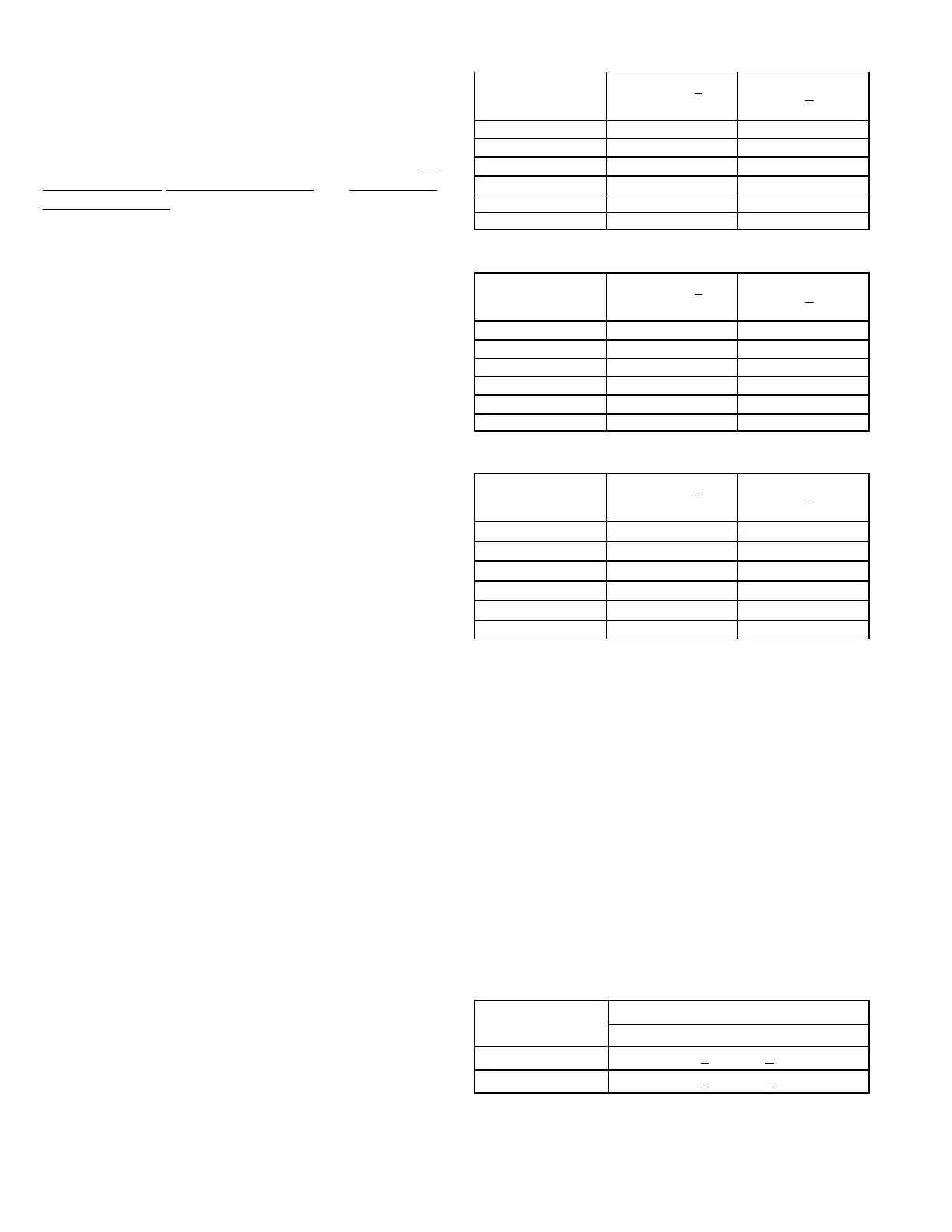

TABLE 22

APPROACH TEMPERATURE - 094, 122, 152

Unit

Liquid Temp. Minus Ambient Temp.

Full Load (Both Compressors)

094 5°F + 1 (2.8°C + 0.5)

122, 152 4°F + 1 (2.2°C + 0.5)

Loading...

Loading...