Page 9

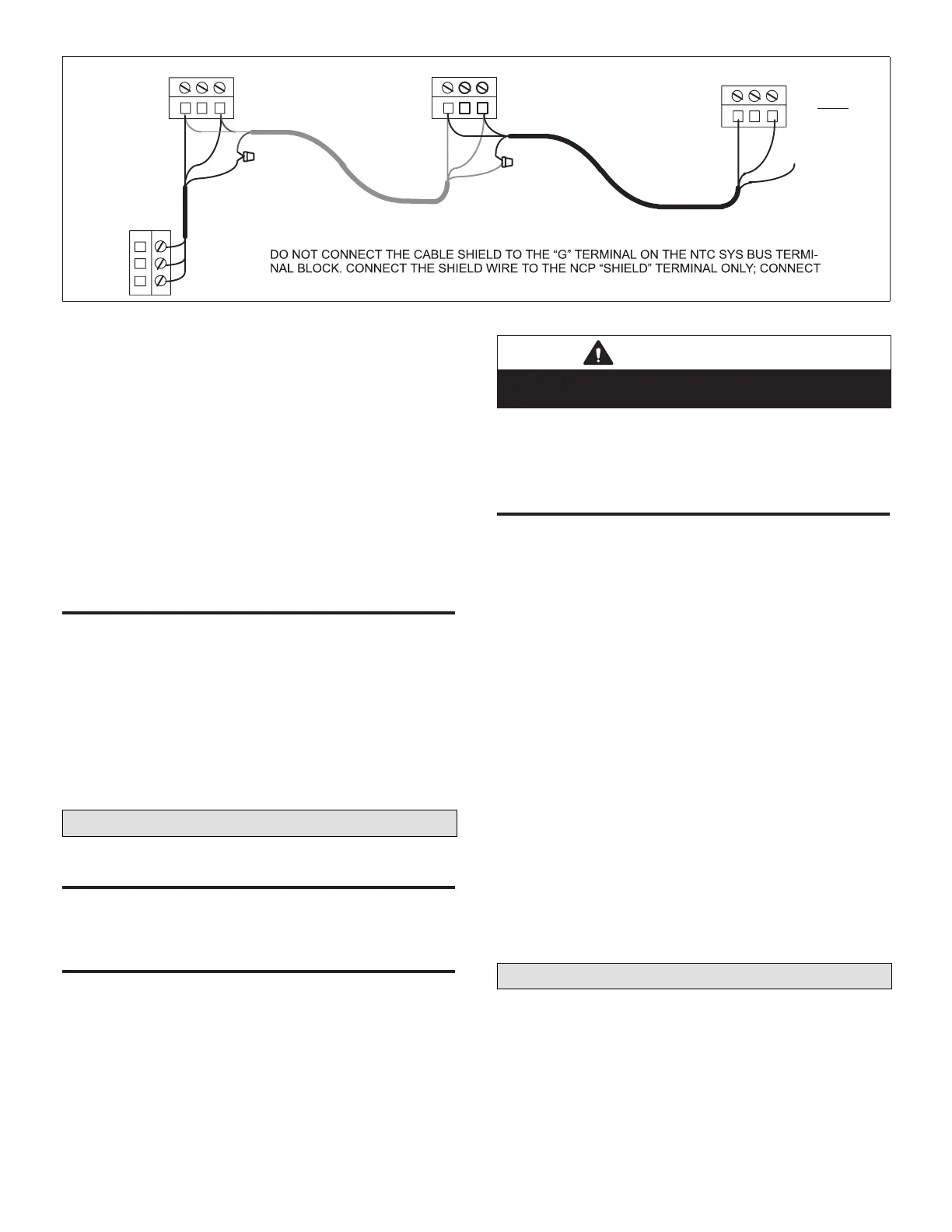

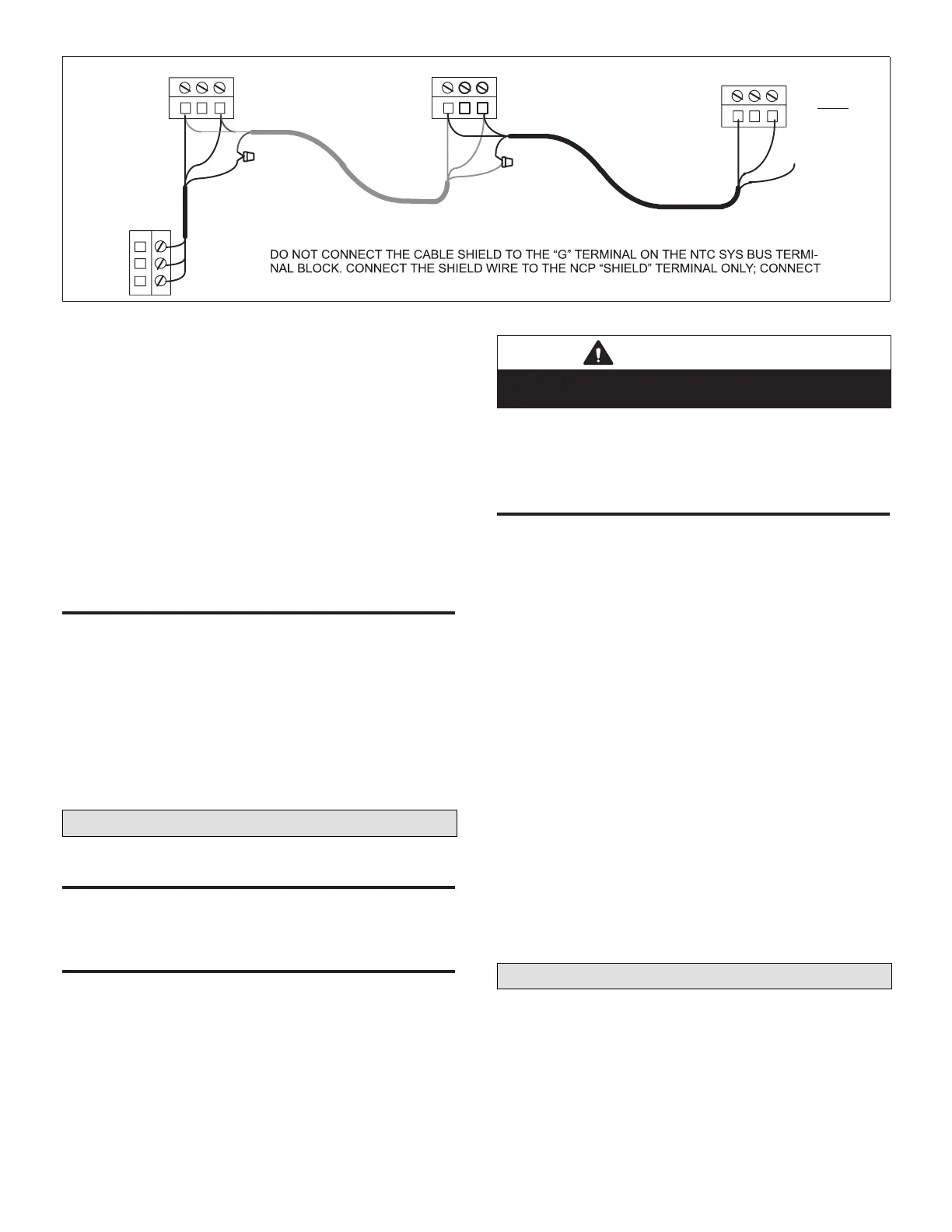

1

2

3

+G −

SYS BUS

ON NCP

SYS BUS

ON NTC

SYS BUS

ON LAST

NTC

+

−

Shield

Shield

Shield

Shield

CONNECT + TERMINALS OF NCP TO + TERMINALS ON THE NTC SYS BUS TERMINAL BLOCK.

CONNECT − TERMINALS OF NCP TO −TERMINALS ON THE NTC SYS BUS TERMINAL BLOCK.

UNIT SHIELD WIRES TOGETHER.

SYS BUS

ON NTC

Figure 11. L Connection Network Daisy−chain Communication Wiring

This input can be used to indicate a blower overload.

Set ECTO A3.04 to option 1. A blower overload must be

installed. If the blower overload trips, the NTC will de−

energize all outputs and issue an alarm code 203 (blower

overload trip). The NTC will retry the input every ve

minutes.

This input can also be used to indicate a loss of phase.

Set A3.04 to option 2. A loss of phase device must be

installed. If the loss of phase device trips, the NTC will

de−energize all outputs and issue an alarm 204 (loss of

phase). The NTC will retry every ve minutes.

NOTE: Connect 24VAC and common wiring to N.C.

terminals when input is not used.

n.o. noRmally open inpUT

The N.O. input is used to de−energize all NTC outputs

when it closes. The NTC will de−energize all outputs and

issue an alarm code 201 (N.O. input is ON). The NTC will

retry every ve minutes.

This input can also be used by a smoke detector. Set

A3.03 to option 1. A smoke detector must be installed.

If the smoke detector trips, the NTC will de−energize all

outputs and issue an alarm code 4 (smoke detector trip).

The NTC will retry every ve minutes.

NOTE: Leave this input open when not used.

Check−Out Procedure

UniT opeRaTion

Use the manual switches to simulate a thermostat demand

and conrm proper unit operation.

wiRing BeTween nTC and UniT

1. Move all manual switches to the OFF position.

2. Apply power to unit.

3. Move the “ G” switch to the ON position to energize the

unit blower.

4. Move the “Y1” switch to the ON position and conrm

the appropriate operation. Move the “Y1” switch to the

OFF position and repeat for each heating and cooling

stage. Proper operation of each function conrms that

the wiring between the NTC and the unit is correct.

IMPORTANT

Do not energize cooling and heating output switches at

the same time

5. Move all switches back to the AUTO position. All

switches must be in the AUTO position to allow the

NTC to control the unit.

nTC opeRaTion

1. Make sure the heartbeat LED is green, energized for

one second and off for one second. This indicates

normal NTC operation. If the LED is green, energized

on for 3 seconds and off for 3 seconds, the NTC is

in an off delay. Press the pushbutton to by−pass the

delay.

2. Make sure the yellow ”XMT” transmit light is blinking.

This indicates that the NTC is transmitting to the

NCP. If the transmit LED is not blinking, make sure

communication wiring connections are correct and

secure and that power is being supplied to the NCP.

NOTE: The transmit LED blinking rate depends on the

number of units connected to the L Connection

bus. The blink rate can be as slow as once every

30 seconds.

3. If an NCP is not connected, the NTC will control the

unit to default settings: 70°F (21°C) heating setpoint,

75°F (24°C) cooling setpoint, and occupied time

period (continuous blower).

4. If the heartbeat is ashing red, the controller is locked

out because of an alarm. Make sure all digital inputs

(P177) are properly connected. The N.C. LED should

be ON. If air ow switch is not used the input must be

jumpered. The service input should normally be OFF

Adjustable Parameters

The NTC default control parameters can be adjusted

using a PC, Unit Controller PC software (version 2.02),

and a PC to L Connection converter.

Loading...

Loading...