Loading...

Loading...

Do you have a question about the Lennox Prodigy 2.0 and is the answer not in the manual?

| Brand | Lennox |

|---|---|

| Model | Prodigy 2.0 |

| Category | Controller |

| Language | English |

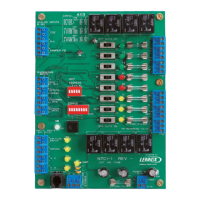

Describes add-on boards connecting to the main board for variations based on application.

Explains M3 Unit Controller operation via wired thermostat, room sensor, or L Connection Zoning.

Details the five different staging options available for cooling operation.

Details the three staging options available for heating operation.

Describes configuring backup modes and lists default set points for room sensor operation.

Details compressor protection mechanisms like minimum run/off times and freeze-stats.

Explains minimum run and off times for compressors, including Energence units.

Describes how freeze-stats protect compressors from low evaporator coil temperatures.

Explains high pressure switches that protect compressors from over-pressurization.

Details thermal protector switches for compressor protection.

Explains low pressure switches that protect compressors from low suction pressure.

Describes how the controller detects loss of power and manages compressor restart.

Details burner protection and timing for gas heat sections.

Details primary/secondary limits that protect the gas heat section.

Explains flame roll-out switches that shut down gas valve upon activation.

Describes operation sequences for combustion air proof switches.

Explains how the controller detects gas valve energization and errors.

Details time delays for gas heat valve operation between stages.

Describes various safety and operational components.

Describes monitoring return air temperature to interrupt demand if limits are exceeded.

Explains how smoke detectors affect unit operation and damper position.

Details using optional inputs for safety switches like blower overload or phase loss.

Explains how the airflow switch monitors air flow and controls compressors/valves.

Describes the function of the dirty filter switch and its alarm indication.

Details the thermal overload relay switch for blower motor protection.

Explains overflow switches that shut off the compressor upon detecting an overflow condition.

Details blower on-delay settings for gas and cooling units.

Details blower off-delay settings for electric, gas, and cooling units.

Defines warm-up mode and economizer damper control during this period.

Explains cool-down delay behavior and economizer function.

Details gas heat output control for up to two gas heat sections.

Details electric heat operation and stage delays.

Explains time delay between first and second-stage electric heat demands.

Details behavior when electric heat limits open.

Lists resistance vs. temperature data for standard thermistors.

Provides resistance vs. temperature data for the optional room sensor.

Describes the analog relative humidity sensor and its output.

Details the analog CO2 sensor and its DC voltage output.

Describes the analog supply duct differential static pressure sensor.

Details optional enthalpy sensors and their output.

Explains the pressure transducer for economizer operation.

Explains outdoor fan operation in high efficiency A Box units at different outdoor temperatures.

Describes outdoor fan cycling by liquid line pressure switch in low ambient conditions.

Details outdoor fan sequence of operations during low ambient conditions.

Explains outdoor fan cycling for other unit types in low ambient conditions.

Explains settings for Supermarket Reheat using de-humidistat or RH sensor.

Details Humiditrol reheat operation based on RH sensor readings and compressor staging.

Explains using digital inputs to control dehumidification via Humiditrol or third-party products.

Describes using heated outside air for dehumidification when outside air temp is low.

Explains selecting minimum damper positions for MSAV blower units.

Details compressor and Humiditrol operation based on thermostat and humidity sensor inputs.

Provides a general overview of economizer controls and functions.

Details enabling the economizer and selecting the applicable economizer type.

Explains operating profile options for the economizer damper during free cooling.

Configures compressor lockout when outdoor air is suitable or below a low ambient set point.

Details the enthalpy set point for single enthalpy free cooling mode.

Explains how to set the maximum damper position for free cooling.

Details menu paths to modify minimum damper positions for high and low operations.

Explains setting the motorized outdoor air damper position and its function.

Provides checkout procedures to confirm economizer operation and damper travel.

Explains using IAQ sensors with economizers to control CO2 levels and damper position.

Provides a general overview of demand control ventilation.

Describes the default operation of the M3 Unit Controller for IAQ input and damper travel.

Details setting maximum and minimum damper positions for DCV.

Explains how to adjust indoor air quality parameters for different applications.

Details controlling single-stage and two-stage power exhaust fans based on configuration.

Summarizes blower delay options for gas/electric and cooling operations.

Explains CAV control mode for units with single-speed blowers.

Explains MSAV control for A Box units with direct-driven or two-speed blowers.

Details MSAV control for A Box units with direct-driven or two-speed blowers.

Explains MSAV control for B Box units with direct-driven or VFD blowers.

Details M3 Unit Controller compatibility with factory-installed VFDs for supply blowers.

Explains CAV control with zone bypass dampers for duct static pressure control.

Details compatibility with specified bypass damper actuators for CAV zoning.

Explains analog output control for CAV bypass dampers using PID or staged control.

Details the discharge air control cooling option for maintaining set points.

Explains using outdoor air reset to adjust discharge air cooling set points based on OAT.

Details using return air reset to adjust discharge air cooling set points based on RAT.

Defines the total reset limit for discharge air control cooling, combining RAT and OAT resets.

Details the discharge air control heating option for maintaining heating set points.

Explains using outdoor air reset to adjust discharge air heating set points as OAT becomes warmer.

Details using return air reset to adjust discharge air heating set points as RAT becomes warmer.

Details M3 Unit Controller operation of bypass dampers for duct static pressure control.

Explains M3 Unit Controller adjustment of fresh air damper based on occupied mode.

Details M3 Unit Controller operation of cooling stages and reset options.

Explains how outdoor air reset saves energy by adjusting discharge air set point.

Explains how return air reset reduces over-cooling by adjusting discharge air set point.

Details M3 Unit Controller operation of heating stages and reset options.

Explains how outdoor air reset saves energy by decreasing discharge air set point as OAT increases.

Explains how return air reset reduces overheating by decreasing discharge air set point as RAT increases.

Details power exhaust fan control options for single/two-stage equipment.

Explains how actuators control supply air volume for CAV units with bypass dampers.

Describes the optional BACnet module for communication with BACnet MSTP networks.

Provides recommendations for setting up BACnet devices on a network.

Lists default BACnet settings for the M3 Unit Controller.

Lists available analog output objects and their valid value ranges.

Lists available analog value objects and their valid ranges and notes.

Lists available analog input objects and their data ranges.

Details how the M3 Unit Controller can be set up to de-energize cooling components for load shedding.

Explains the default operation of the Service Relay output and its use as a control output.

Lists options for system relative humidity monitoring.

Lists options for system indoor air quality monitoring.

Lists options for system outdoor air temperature operation.

Refers to Appendix A for control parameter definitions.

Refers to Appendix B for diagnostic information.

Explains using network control panels for scheduling and daisy-chaining controllers.

Details the calibration procedure for the Advanced Airflow System.

Explains the blower diagnostics process during calibration.

Describes the damper diagnostic steps during calibration.

Details calculating and controlling target OA CFM based on various modes.

Explains under and over ventilation alarms and their causes.

Details damper actuator control voltage inputs and feedback, and stuck conditions.

Lists CFM values for various airflow targets by model for A Box units.

Explains different control modes for the unit controller.

Details M3 Unit Controller operation using room sensor for temp, staging, and diagnostics.

Explains M3 Unit Controller operation via thermostat, controlling staging and general operation.

Provides general information on unit operations applicable to all rooftop units.

Explains DCV use for fresh air based on CO2 levels and damper position.

Describes fresh air tempering to minimize temperature fluctuations using heating/cooling.

Details discharge air cooling reset for energy savings and preventing over-cooling.

Details discharge air heating reset for energy savings and preventing overheating.

Details M3 Unit Controller operation in room sensor mode for HVAC staging.

Details M3 Unit Controller's direct control over compressor staging based on room sensor.

Explains economizer and fresh air use for cooling demand.

Details M3 Unit Controller's direct control over heating staging based on temperature sensor.

Details humiditrol operation for dehumidification demand using reheat.

Details humiditrol operation for combined cooling and dehumidification demands.

Details M3 Unit Controller operation in thermostat mode for 2-heat/2-cool systems.

Details M3 Unit Controller's control of compressor stages for cooling demand.

Details M3 Unit Controller's activation of heating sections for heating demand.

Details M3 Unit Controller operation for discharge air temp control with thermostat/3rd party.

Details M3 Unit Controller operation in thermostat mode for bypass zoning.

Explains bypass damper function for maintaining supply duct static pressure.

Details M3 Unit Controller operation with 3rd party controller for discharge air temp control.

Explains bypass damper function for maintaining supply duct static pressure.

Details terminal connections for thermostat signals.

Details terminal connections for IAQ sensors.

Details terminal connections for safety inputs.

Illustrates the primary levels of the M3 Unit Controller user interface menu.

Explains how to navigate and use the M3 Unit Controller menu interface.

Explains selecting the dehumidifier sensor type.

Details network integration options like L-Connection, BACnet, and RTU Standalone.

Covers blower calibration, speed settings, and RPM adjustments.

Details economizer settings, airflow alarms, and damper position settings.

Explains enabling fresh air heating and its setpoint.

Explains enabling fresh air cooling and its setpoint.

Explains how to clear delays via the user interface.

Describes rebooting the M3 Unit Controller.

Explains how to enable or disable controller lockout.

Details blower speed settings for different operating modes and unit types.

Explains engaging or disengaging VFD bypass.

Details economizer settings, airflow alarms, and damper position settings.

Explains dehumidifier sensor type and setpoint configuration.

Allows direct entry of parameter data IDs for modification.

Details initial setup for new units, including language and display units.

Details how network status (LON, BACnet, L-Connection, RTU) is displayed.

Lists possible mode messages displayed on the unit, including setpoints.

Explains the meaning of various LED indicators on the circuit board.

Explains how to set Configuration ID 1 for unit features like Humiditrol, Economizer, and Network.

Explains how to set Configuration ID 2 for various switches and features.

Recommends PC software for adjusting parameters and saving configuration files.

Details parameters for electric heat warm-up, blower delays, and stage limits.

Lists parameters for gas heat warm-up, blower delays, and high fire settings.

Covers parameters for smoke alarm control, error time off delay, and staging options.

Details parameters for occupied/unoccupied set points and after-hours override.

Lists parameters for fresh air heating/cooling stage differentials and set points.

Lists parameters for discharge air control cooling and heating resets.

Lists parameters for exhaust fan damper control and airflow calibration.

Covers parameters for free cooling lockout, fresh air heating/cooling setpoints.

Cross-references M2 ECTO parameters to M3 parameters for settings menu accessibility.

Explains how the M3 unit controller detects and alarms for incorrect frequency, phasing, and voltage.

Describes alarms related to power loss detection.

Details the alarm for smoke detector input activation.

Describes alarms for compressor high pressure or high temperature.

Details alarms for compressor high pressure.

Explains alarms related to phase monitor status.

Describes alarms for compressor low pressure.

Details alarms for drain plan overflow shutdown.

Describes alarms for compressor freeze stat activation.

Explains alarms for return air overheating.

Details alarms for blower motor overload.

Describes alarms related to heat section combustion air switch.

Explains alarms for no proof gas valve.

Details alarms for primary heat limit switch.

Explains alarms for secondary heat limit switch.

Details alarms for electric heat limit switch.

Explains alarms for flame roll out switch.

Details alarms for network sensor errors.

Explains alarms for zone (room) sensor readings out of range.

Details alarms for outdoor temperature sensor readings out of range.

Explains alarms for humidity sensor readings out of range or for dehumidification mode.

Details alarms for discharge air temperature sensor readings out of range.

Explains alarms for return air temperature sensor readings out of range.

Details alarms for add-on board communication issues.

Explains reheat setup error alarms.

Details alarms for incorrect hardware configuration settings.

Explains alarms for incorrect Humiditrol settings.

Details alarms for conflicting thermostat inputs.

Explains alarms for outdoor air differential pressure sensor errors.

Explains alarms for VFD shutdown due to faults or overload.

Explains alarms for low supply CFM detected by Advance Airflow.

Details alarms indicating low blower RPM or non-working blower.

Explains alarms for outdoor air damper or economizer mechanical faults.

Details alarms for low outdoor airflow affecting IAQ.

Explains alarms for excessive outdoor airflow leading to wasted energy.

Details alarms when MSAV blower settings are below target CFM.

Explains alarms when MSAV blower settings are above target CFM.

Details alarms for low secondary 24VAC voltage.

Explains alarms for high secondary 24VAC voltage.

Details alarms for incorrect line phasing detected by the Phase-Voltage Detection feature.

Explains alarms for VFD shutdown due to faults or overload.

Details alarms indicating target airflow cannot be achieved due to reduction.

Details terminal connections for thermostat signals.

Details terminal connections for IAQ sensors.

Details terminal connections for safety inputs.