Application examples

4.2 Example 2: Spray nozzle control

4−7

l

EDSVS9332P−EXT DE 2.0

4.2 Example 2: Spray nozzle control

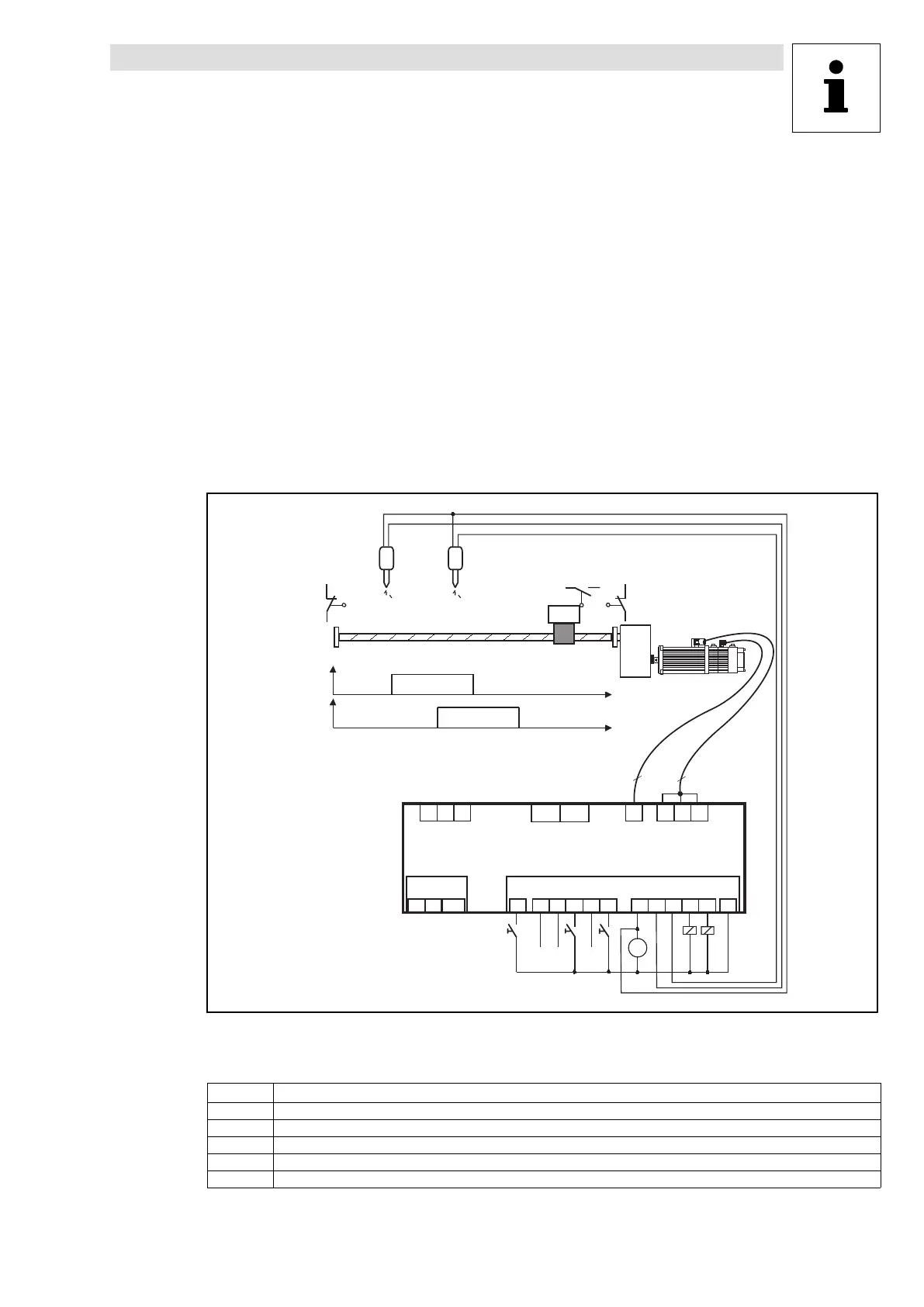

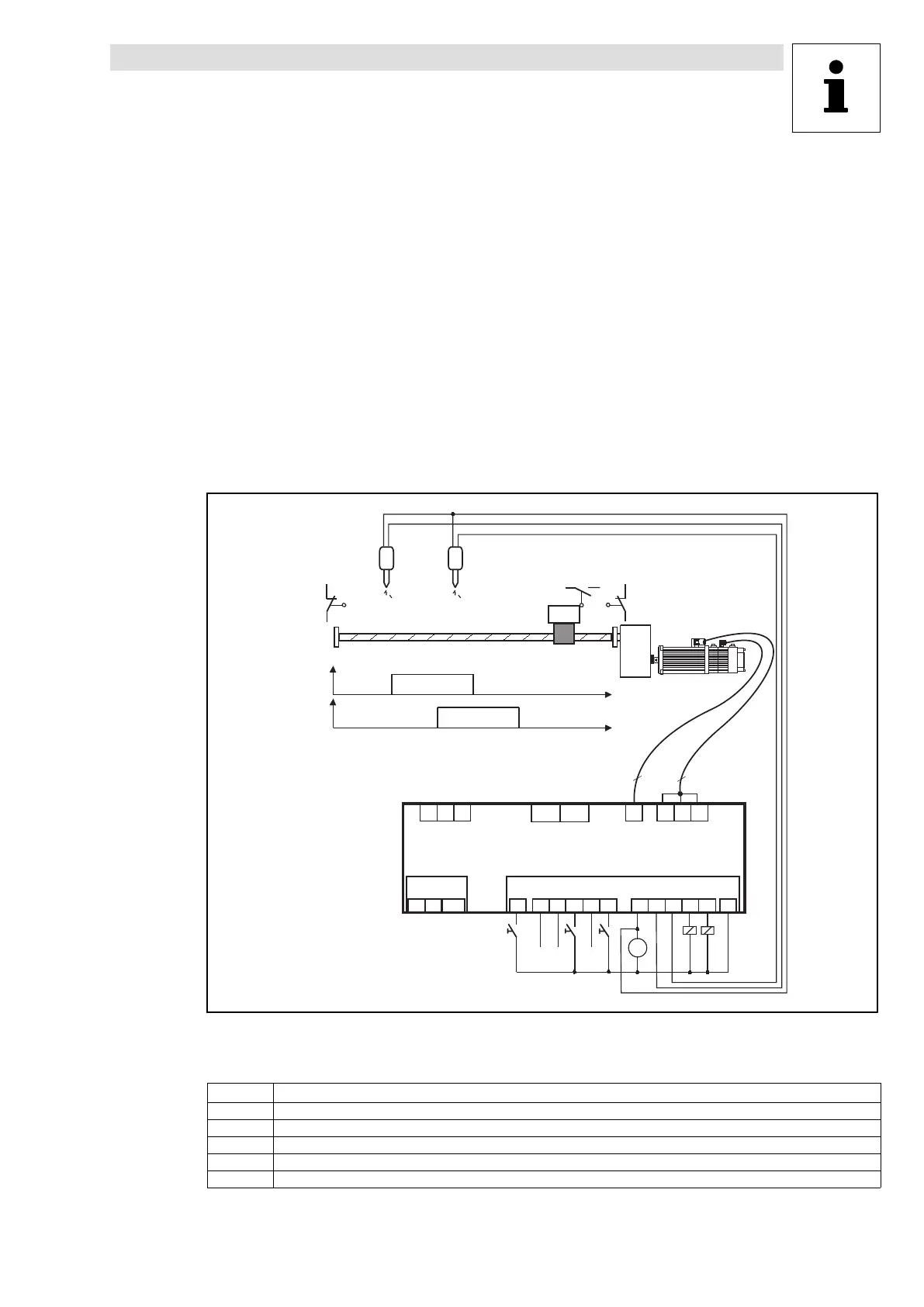

The combination of the spray nozzle control and the positioning of the workpiece are required for

printing machines and painting equipment. Previously a cam controller was used. However,

mechanical inaccuracies and wear often led to bad results. The absolute positioning in the 9300

servo position controllers and open control structure enables the nozzle control to be provided with

the corresponding messages. They can be read via a fieldbus or (as shown in the example) output

via the terminals.

The spray nozzle control in Fig. 4−3 is an example of absolute positioning, which replaces former

applications with mechanical cam groups.

These applications do not require mechanical limit switches or initiators that were used to be

necessary to detect the position. Using the evaluation electronics of the 9300 servo position

controller, the position information of the fed part is determined and positioned.

X5

28 E1 E2 E3 E4 E5 A1 A2 A3

A4 59

L3L2L1

39

+UG -UG

93XX

WVU

HI LO

GND

X4

RFR

24V

=

+

-

S4

S4

X7

S1

S2

S2S1

X5/A1

X5/A2

s

s

39

Fig. 4−3 Example of an absolute positioning with the ’SP1’ function block (position switch points)

Input

Function

E1 Limit switch (S1) negative direction

E2 Limit switch (S2) positive direction

E3 Start program

E4 Homing switch (S4)

E5 Changeover manual jog / program mode

Loading...

Loading...