For the MS31x and MS41x printer models, you can load paper labels up to 50 sheets in the standard tray and up to the

full capacity of the optional trays. You can load up to 15 paper labels and up to 10 sheets of card stock in the multipurpose

feeder.

For the MS51x and MS61x printer models, you can load paper labels up to the full capacity of the standard tray and

the optional trays. You can load up to 30 paper labels and up to 20 sheets of card stock in the multipurpose feeder.

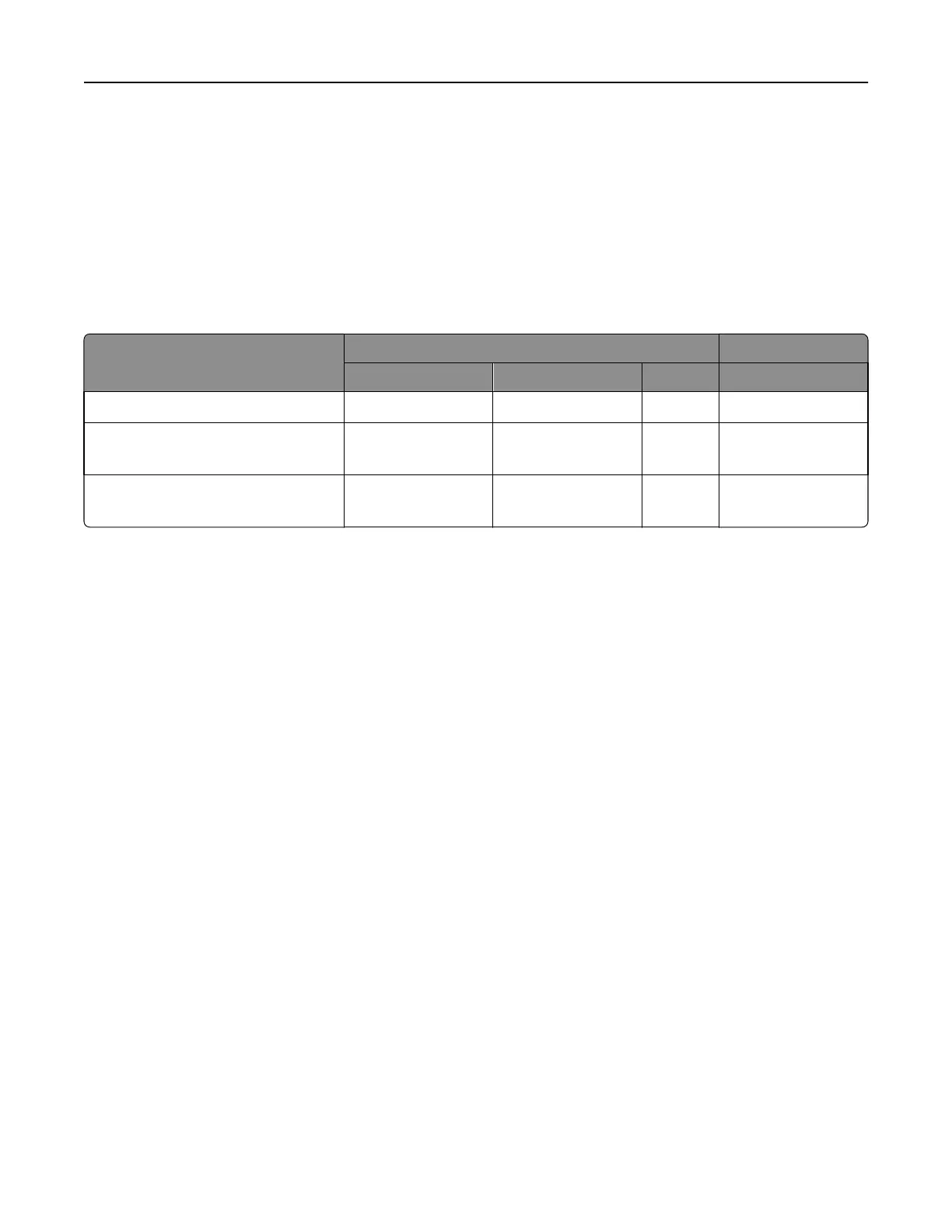

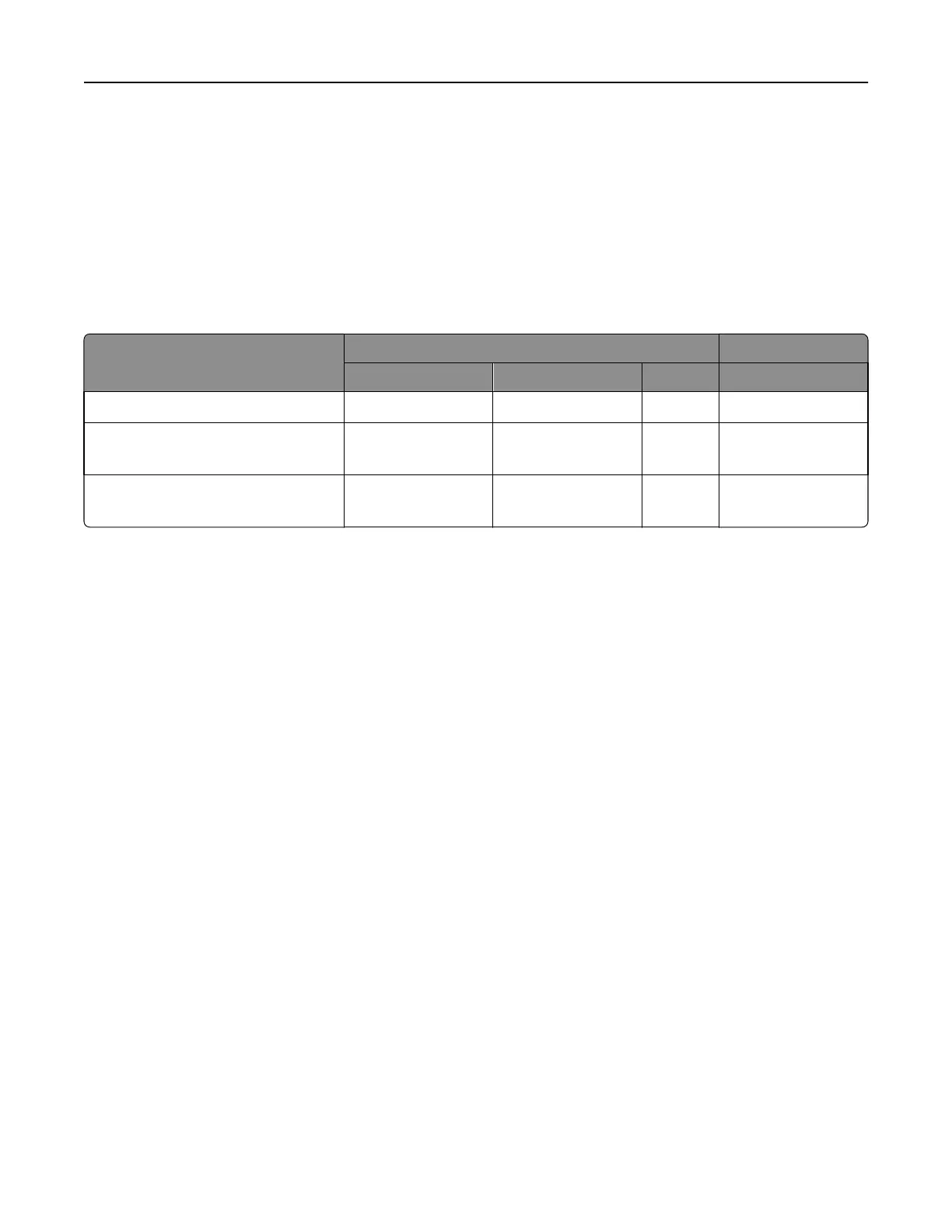

The following table lists the maximum weights supported by the standard tray, the optional 250‑ and 550‑sheet trays,

and the multipurpose and manual feeders.

Overview of card stock and label support

Paper source

Card Stock Labels

Index Bristol Tag Cover Paper

Standard tray — — —

60–90 g/m

2

Optional 250‑sheet tray

Optional 550‑sheet tray

———

60–120 g/m

2

Manual feeder

Multipurpose feeder

60–163 g/m

2

60–163 g/m

2

—

60‑163 g/m

2

Media specifications

Labels Width: 210–216 mm (8.3–8.5 in.)

Length: 279–297 mm (11–11.7 in.)

Weight:

Up to 163 g/m

2

(43 lb)

Thickness: Up to 0.25 mm (0.01 in.)

Smoothness: 100–400* Sheffield

*150–250 Sheffield is optimal. Using media higher than 300 Sheffield could result in printing degradation.

Card stock Weight:

Up to 163 g/m

2

Index Bristol (90 lb)

Up to 163 g/m

2

Tag (100 lb)

When printing on labels:

• Check with the manufacturer or vendor to ensure the labels can withstand temperatures up to 210°C (410°F) without

sealing, curling excessively, wrinkling, or releasing hazardous emissions.

• Check with the manufacturer or vendor to ensure the labels can withstand 25 psi (172 kPa) pressure without

delaminating, oozing around the edges, or releasing hazardous fumes.

• Do not use labels with slick backing material.

• Use full label sheets. Partial sheets may cause labels to peel off during printing, resulting in a jam.

• Do not use labels with exposed adhesive.

• Do not print within 1 mm (0.04 in.) of the edge of the label, of the perforations, or between die‑cuts on the label.

• Be sure adhesive backing does not reach to the sheet edge. Zone coating of the adhesive at least 1 mm (0.04 in.)

away from the edges is recommended. Adhesive material contaminates the printer and could void the warranty.

• If zone coating of the adhesive is not possible, remove a 1.6 mm (0.06 in.) strip on the leading and driver edge, and

use a non‑oozing adhesive.

• Portrait orientation works best, especially when printing bar codes.

Printer specifications 78

Loading...

Loading...