7

lci1.com 574 - 537- 890 0 Rev: 11.16.18

Solera

®

Classic Awning

Installation and Owner’s Manual

(For Aftermarket Applications)

CCD-0001254

FAILURE TO MAINTAIN CONTROL OF THE ROLL

TUBE, FABRIC AND SUPPORT ARM ASSEMBLIES

MAY RESULT IN SERIOUS PERSONAL INJURY OR

PROPERTY DAMAGE.

USE CARE WHEN REMOVING THE COTTER PINS.

THE COTTER PINS ARE HOLDING THE PRE-WOUND

TENSION OF THE SPRING. FAILURE TO SECURELY

HOLD THE ROLL TUBE MAY ALLOW THE ROLL

TUBE TO RAPIDLY ROLL UP AND CAUSE PERSONAL

INJURY OR DAMAGE.

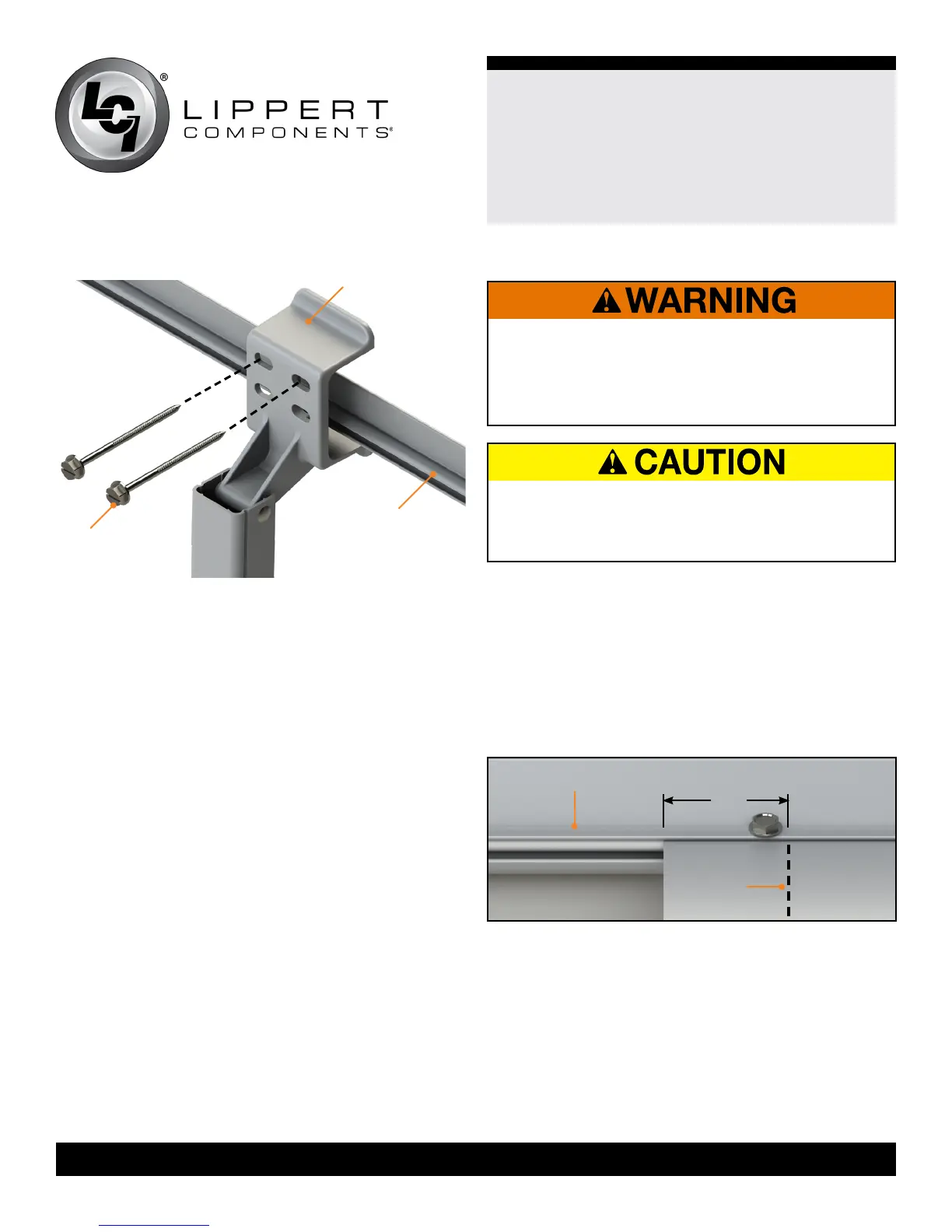

Securing the Fabric

1. Roll the awning in and out several times to ensure that

the fabric is square on the roll tube.

2. Secure the fabric in the awning rail no more than 1”

inside the edge of the fabric on both ends using a #6 x

½” hex. head screw. Install the screw down through the

awning rail into the fabric and the polycord (Fig.10).

Awning Rail

1”

Fabric

Stitching

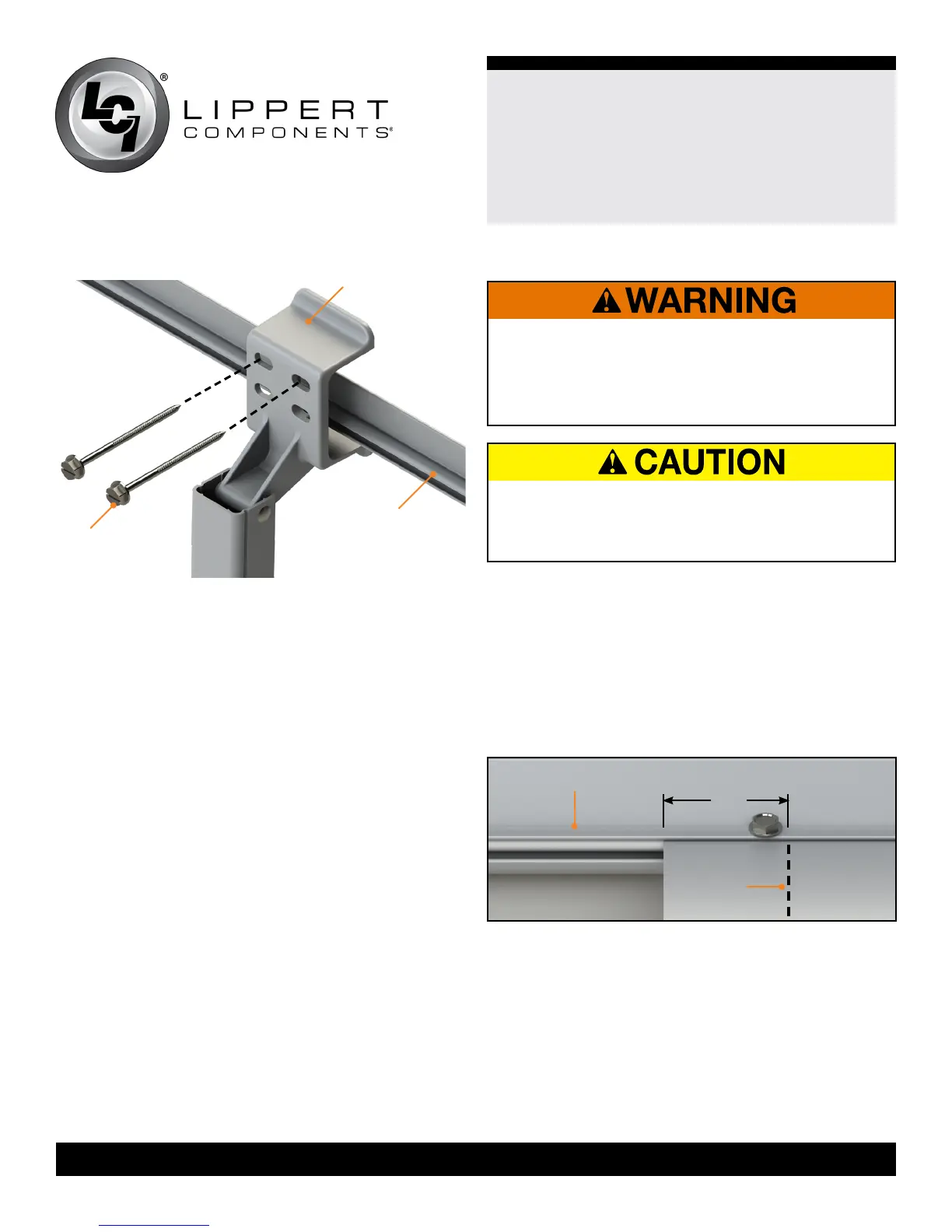

10. Once the upper bracket is placed, mark and pre-drill

two 3/16” holes through the awning rail or unit.

A. Apply a liberal amount of silicone sealant over the

holes.

B. Attach the upper mounting bracket using the provided

¼” x 3” lag screws provided (Fig.9).

NOTE: All screws supporting the awning assembly MUST

have a backer within the structure of the wall of the unit.

Refer to the unit’s manufacturer for proper backer location.

It is acceptable that the lag screws go through the at

portion of the awning rail.

11. Repeat step 10 for the other support arm assembly.

NOTE: Prior to completing removing cotter pins in step 12,

make sure the cam lock is on the roll out position.

12. Firmly grasp the roll tube and head and remove the

safety cotter pin from each end of the roll tube. Keeping a

rm grasp on the roll tube and head, place the cam lock in

the roll up position.

13. Allow the fabric to slowly roll up.

Fig.10

Fig.9

Upper Mounting

Bracket

Awning Rail

Lag Screw

Loading...

Loading...