5 -28

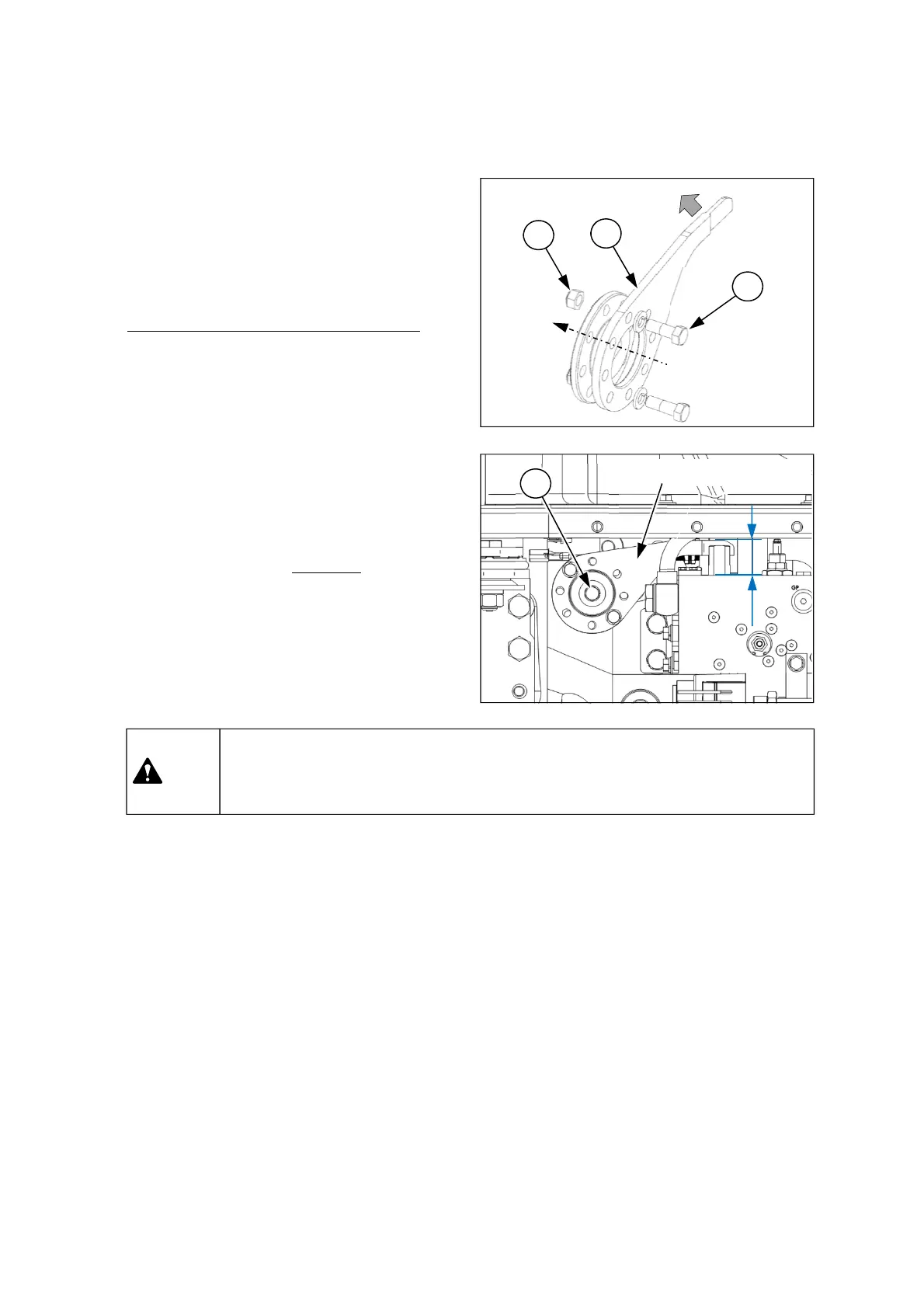

Unscrew the two bolts④ and rotate the clutch

arm③ counter-clockwise by 2.5 degrees.

Assemble the two bolts④ with washers and nuts

⑤ into the next assembly holes counter-

clockwise from the previous attached holes.

Tighten the two bolts.

Tightening torque: 34~39 N.m (25~29 lb-ft)

Note: This rule must be adapted when you

adjust the clutch arm next times.

3

4

5

Clutch arm assembly

2

“H”

▶If the clutch arm assembly is not adjusted on time, it may cause a rapid/earlier

clutch disk abrasion and damage of the synchro-mech gears.

Caution

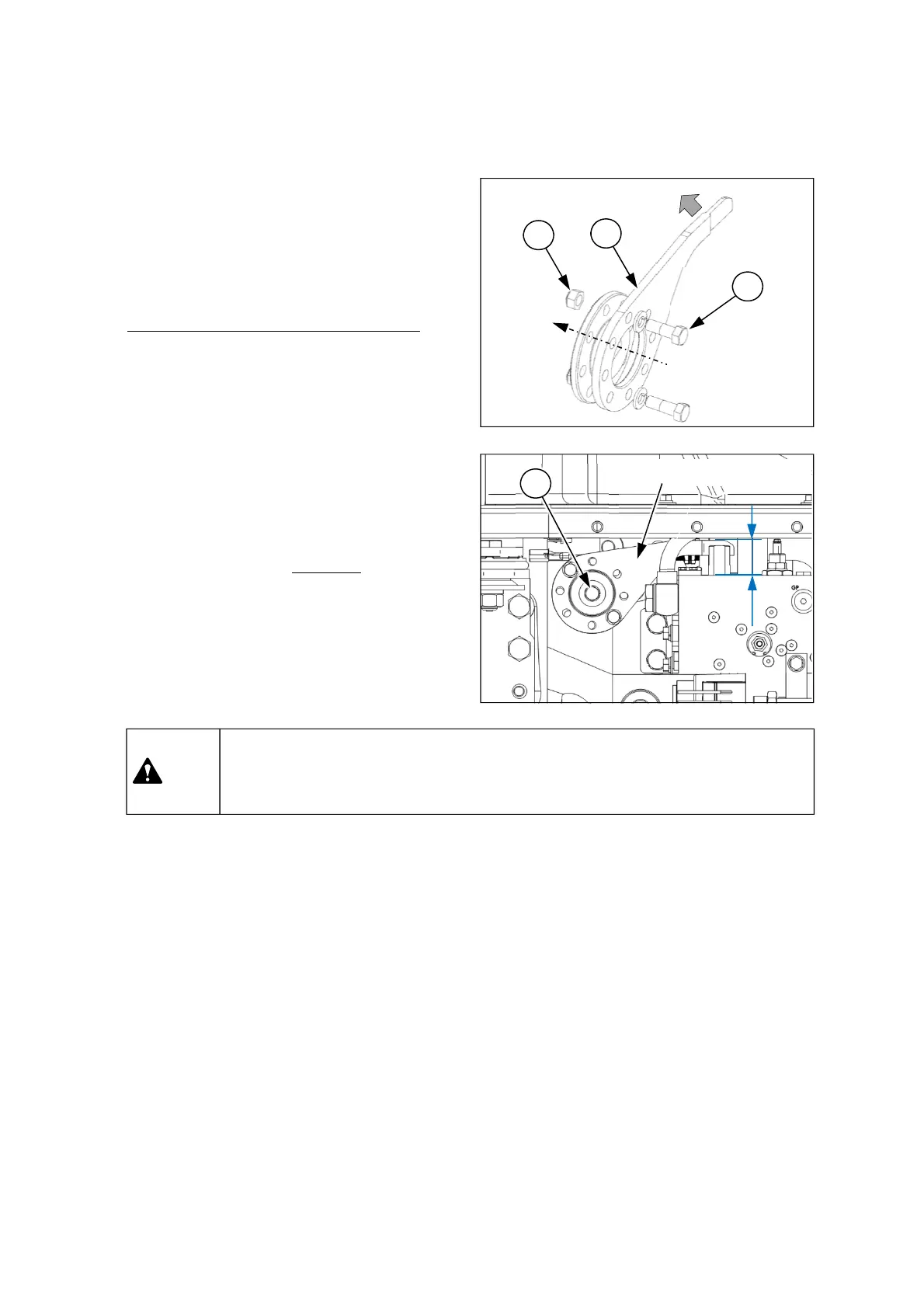

Assemble the clutch arm assembly to the tractor

in the reverse order of disassembly, and tighten

the bolt②.

Check if the height(“H”) of the clutch arm from

the valve block is about 35~36mm after

adjustment.

New assembly hole

Counter-clockwise

Loading...

Loading...