P 7/ 19

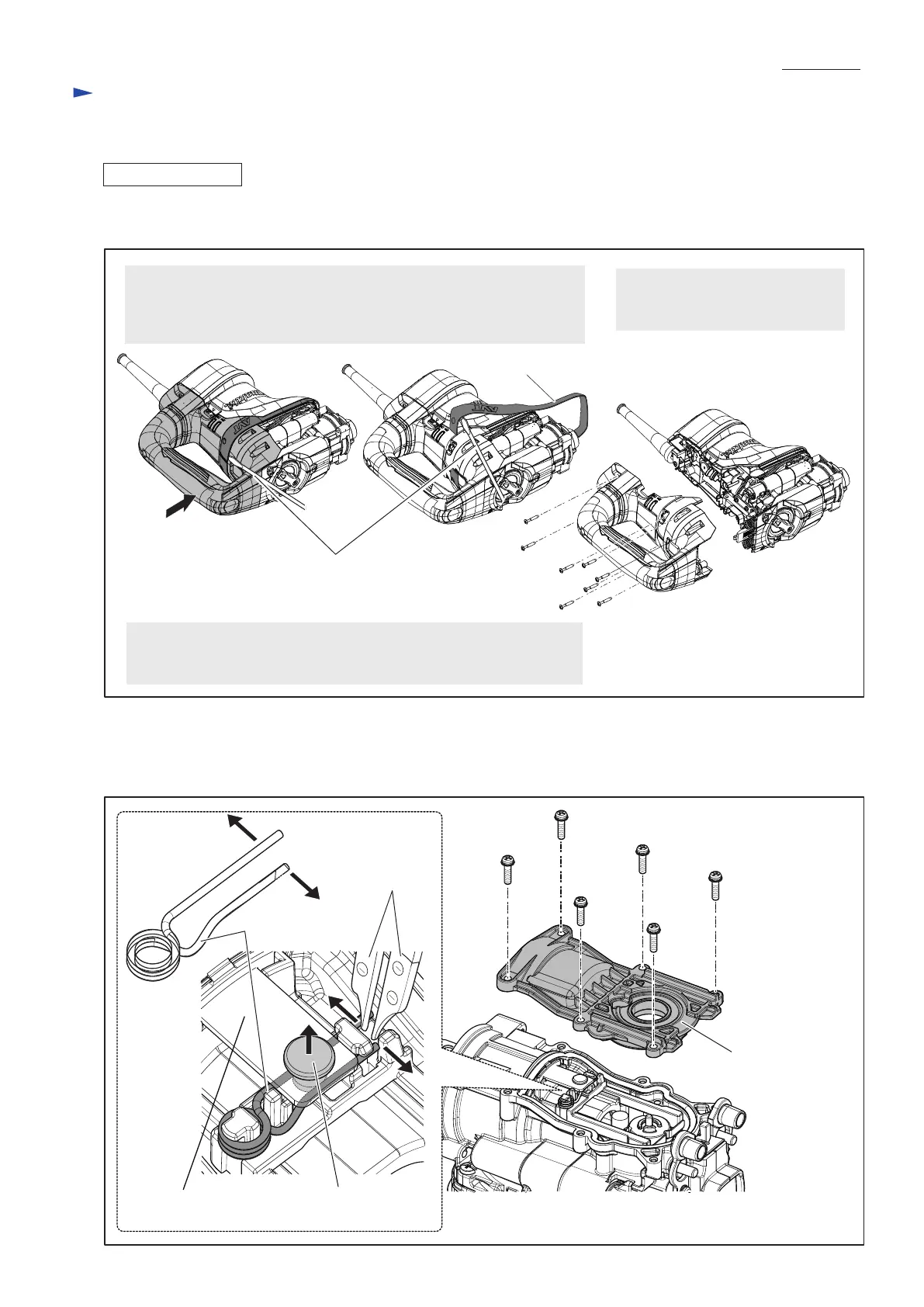

DISASSEMBLING

Fig. 10

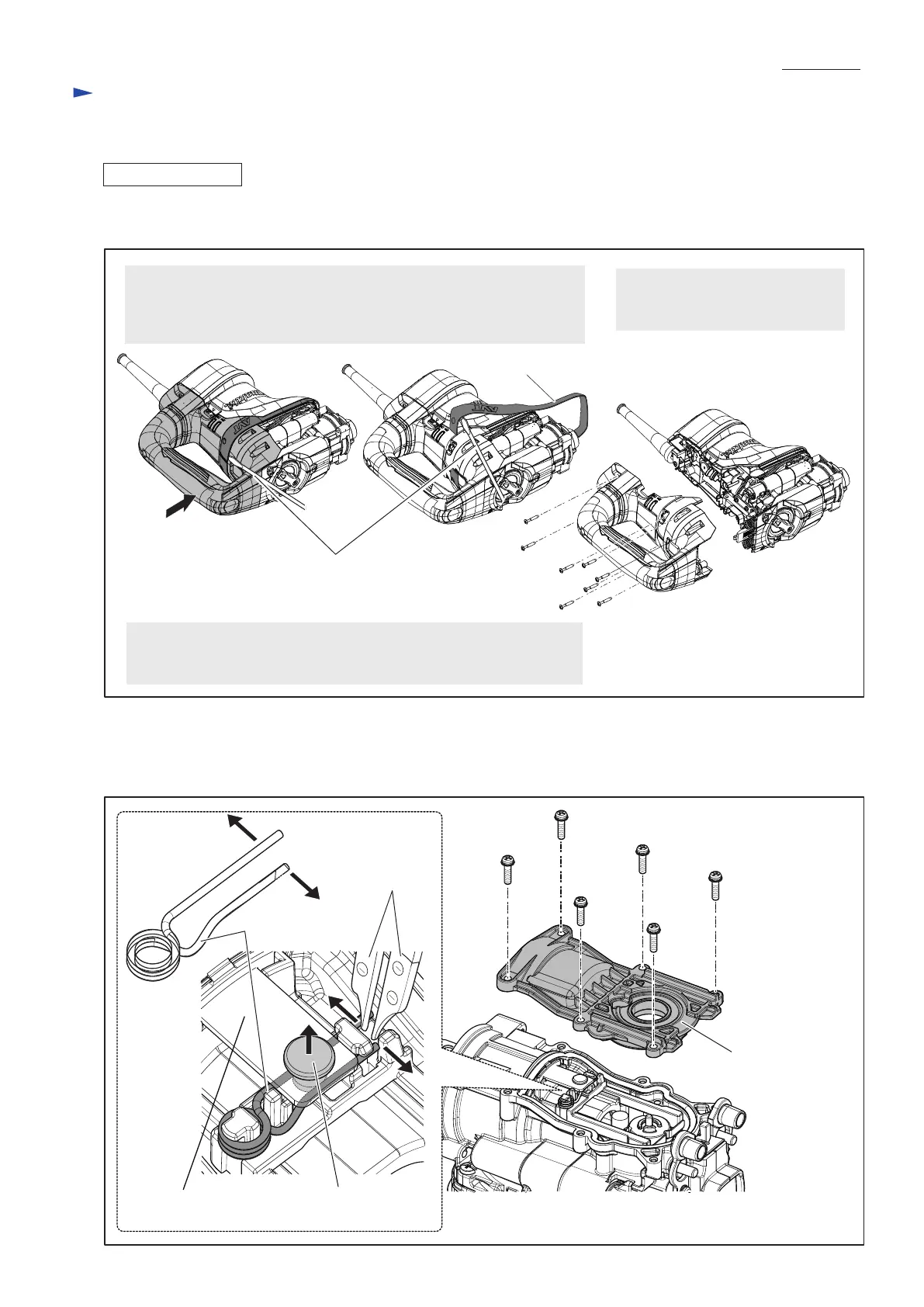

Fig. 11

(1) After removing Barrel section as drawn in Fig. 6, disassemble Handle section as drawn in Fig. 10.

(2) Remove six M4x16 Pan head screws and Crank cap.

While expanding the ends of Torsion spring 7 with 1R003, remove Flat fillister head pin 6 on Link plate. (Fig. 11)

As for HR4003C,

• the removal precess of Guard 40 can be skipped.

• Disassemble Handle section by unscrewing six 4x25 Tapping screws.

1. Reserve the insertion slit for a slotted screwdriver between Guard 40

and Handle base for HR4013C by pressing Handle section toward

Crank housing side.

And remove Guard 40 by prying it up with a slotted screwdriver.

2. Disassemble Handle section for

HR4013C by unscrewing eight

4x25 Tapping screws.

Guard 40

Slotted screwdriver

[3] DISASSEMBLY/ASSEMBLY

[3]-3. Crank housing, Cylinder, Counter weight

Repair

4x25 Tapping screw

(8 pcs.)

Torsion spring 7

1R003

Flat fillister head pin 6Link plate

M4x16 Pan head screw (6 pcs.)

Crank cap

Loading...

Loading...